Crushed Stone Base Course

2021-02-22T05:02:14+00:00

[PDF] PERFORMANCE OF CRUSHEDSTONE BASE

Good performance of the engineered crushedstone base is attributed to (a) a uniform, high degree of density (100 percent of AASHTO T180), (b) use of a wellgraded crushed stone with 1 to 2in (25 to 50mm) top size that has only 4 to 5 percent passing the No 200 sieve, (c) practically no segregation, and (d) a relatively thin asphaltconcrete surfacingIn this study the use of crushedstone base is evaluated as an alternative to the deep strength as phaltconcrete construction now used by the Georgia Department of Transportation (GDOT) in flexible pavements Twelve largescale pavement sections were tested to determine whether engineered crushed stonePerformance of CrushedStone Base CoursesAggregate “base course” refers specifically to the underlying concrete layer of a road or track, over which the wearing course is poured While aggregate base course is typically made from materials mined directly from the earth, aggregates can also be made from recycled concrete, called crushed concrete aggregate Aggregate Base Course Aggregate base is typically made by combining different sizes of crushed Aggregate Base Course vs Crushed Concrete In pavements, Base Course is a sublayer material that provides a supportive foundation on sidewalks top layers, that is placed directly on the undisturbed soil The aggregates derive from concrete, recycled asphalt, or quarried rock Structural Uses of Aggregate Base When doing structural foundations or base course under concrete slabs and asphalt pavement What is crushed aggregate base? 211 Crushed stone base course (coarse gradation) Acceptable sand may be blended as necessary to obtain the proper gradation for the fine aggregate portion 2111 The substitution of crushed stone meeting the requirements of crushed stone base course (fine gradation) for all or part of this item will be permitted Construction RequirementsSECTION 304 AGGREGATE BASE COURSE

PARTIAL REPLACEMENT OF CRUSHED AGGREGATE BASE

24 Base course Material specifications as per ERA Manual The particle size distribution recommended by [3] for crushed stone base course materials (GB1) is shown in table 21 Table 21: Grading Limits for Graded Crushed Stone Base Course Materials (GB1) [3] Test sieve (mm) Nominal maximum particle size 375 Crushed Aggregate Base Coarse (Compaction Gravel) shall consist of one or more courses or layers of coarse aggregate, either crushed gravel or crushed stone, fine aggregate and binder or filler blended as necessary to produce an intimate mixture of the Specifications For CRUSHED AGGREGATE BASE COARSE CEMENT STABILIZED CRUSHED AGGREGATE BASE COURSE 2311 Description This item shall consist of a foundation for surface course or for other base courses and shall be composed of a mixture of crushed aggregate, Portland cement and water and shall be constructed as herein specified and in conformity with the typical cross sections shown onItem 00231 Cements Stabilized Crushed Aggregate Base South Florida roads use crushed limestone base A typical section is 1 inch bituminous, 6 to 8 inches limerock, and 12 inch 'stabilized subgrade' ie, the native sand with enough limerock mixed in to stabilize it to LBR 40 In this case, LBR = Limerock Bearing Ratio, which is equivalent to about 80% CBRWich important tests are required on crushed stone Good performance of the engineered crushedstone base is attributed to (a) a uniform, high degree of density (100 percent of AASHTO T180), (b) use of a wellgraded crushed stone with 1 to 2in (25 to 50mm) top size that has only 4 to 5 percent passing the No 200 sieve, (c) practically no segregation, and (d) a relatively thin asphalt [PDF] PERFORMANCE OF CRUSHEDSTONE BASE

Redash Base Course Materials with Crushed Stone

crushed stone aggregate for base course material of Asphalt concrete The experiments evaluate the Mechanical and physical properties of redash AASHTO, BS and ERA manuals specifications were the followed procedure during specimens taken, and laboratories test were performed The samples were collected andCrushed rock base course This paper discusses the use of crushed rock as pavement base course material by Local Government Authorities in Perth Recent experience derived from use of a crushed rock base course in the City of Canning has shown that under certain circumstances the expected properties and performance of crushed rock are not Crushed rock base course Transportation Research I'm currently supervising a road designed to a bitumen standardsurfacedressingThe pavement layers composes of stabilised subbase,crushed stone base(CRR)and surfacingNow I'm at base course stage and in principle Ihave already analysing the most important tests required for the assessment of the rock to be used as stone baseThe tests already conducted are grading Wich important tests are required on crushed stone outlined in Item 2305, of "Crushed Aggregate Base Course" 2316 Measurement "Cement Stabilized Crushed Aggregate Base", will be measured by the square yard of material, furnished and compacted in place and to the thickness specified, or as shown on the plansItem 00231 Cements Stabilized Crushed Aggregate Base In general, the base layer aggregate composed of gravel exhibited low soaked CBR values compared with typical crushed stone layer materials The crushed stone particles with angular shape and rough surface texture result in better interlocking and resistance to penetration compared with natural gravel particles with round/semi round particlesLong term performance of gravel base course layers in

Table 3602/1 CRUSHED STONE BASE AND SUBBASE:

Table 3602/1 CRUSHED STONE BASE AND SUBBASE: MATERIAL REQUIREMENTS Material TYPE OF MATERIAL Only fines crushed from the May contain UP to May contain UP to 15% by same sound parent rock may be 10% by mass of mass of approved natural fines Table 3402/4 REQUIREMENTS FOR GRAVEL WEARING COURSEAggregate Base Course Aggregate Base Course often referred simply as ABC, has certain desirable properties Base Course in pavements refers to the sublayer material of an asphalt roadway and is placed directly on top of the undisturbed soil (SubGrade) so as to provide a foundation to support the top layers of the pavementAggregate Base Course Acme Sand Gravel (2) Stone or Crushed Slag (3) Cement Stabilized SandClayGravel (4) Asphaltic Concrete Base Course on Treated Layer (5) Recycled Portland Cement Concrete The base course shall be a selected base course type required to meet the structural requirements for a PART III BASE COURSES A Aggregate base course shall be applied over the prepared sub grade or sub base and compacted in accordance with Section 26 of the Caltrans Standard Specifications B Aggregate base course shall have minimum uniform thickness after compaction of dimensions indicated Where not indicated, compacted thickness shall be 6 inches C All 32 11 23 Aggregate Base Course Cement Stabilized Crushed Stone Base Course Strength and Stiffness Analysis Theses and Dissertations Retrieved from https://scholarworksuarkedu/etd/3886 This Thesis is brought to you for free and open access by ScholarWorks@UARK It has been accepted for inclusionCement Stabilized Crushed Stone Base Course Strength

Redash Base Course Materials with Crushed Stone

crushed stone aggregate for base course material of Asphalt concrete The experiments evaluate the Mechanical and physical properties of redash AASHTO, BS and ERA manuals specifications were the followed procedure during specimens taken, and laboratories test were performed The samples were collected andAggregate Base Course Aggregate Base Course often referred simply as ABC, has certain desirable properties Base Course in pavements refers to the sublayer material of an asphalt roadway and is placed directly on top of the undisturbed soil (SubGrade) so as to provide a foundation to support the top layers of the pavementAggregate Base Course Acme Sand Gravel CITY OF PEARLAND BASE COURSE FOR PAVEMENT 5/2013 02710 1 of 12 Section 02710 BASE COURSE FOR PAVEMENT 10 G E N E R A L 101 SECTION INCLUDES A Base course of crushed stone, recycled crushed concrete base, cementstabilized crushed stone, cement stabilized bank run gravel, recycled crushed stone and hot mix asphalt base course02710Base Course for Pavement Pearland, TX Table 3602/1 CRUSHED STONE BASE AND SUBBASE: MATERIAL REQUIREMENTS Material TYPE OF MATERIAL Only fines crushed from the May contain UP to May contain UP to 15% by same sound parent rock may be 10% by mass of mass of approved natural fines Table 3402/4 REQUIREMENTS FOR GRAVEL WEARING COURSETable 3602/1 CRUSHED STONE BASE AND SUBBASE: In general, the base layer aggregate composed of gravel exhibited low soaked CBR values compared with typical crushed stone layer materials The crushed stone particles with angular shape and rough surface texture result in better interlocking and resistance to penetration compared with natural gravel particles with round/semi round particlesLong term performance of gravel base course layers in

Division 6: Aggregate Base And Subbase Course

Division 6: Aggregate Base And Subbase Course 601 SCOPE: Aggregate Base and Subbase Course shall consist of natural or artificial m ixtures of natural or crushed gravel, crushed stone or slag 602 MATERIALS: Aggregate Base and Subbase Course will be designated as Type I and shall consist of crushed stone, crushed slag or crushed gravel, with or without soil mortar or other adm ixtures A Aggregate base course shall be applied over the prepared sub grade or sub base and compacted in accordance with Section 26 of the Caltrans Standard Specifications B Aggregate base course shall have minimum uniform thickness after compaction of dimensions indicated Where not indicated, compacted thickness shall be 6 inches C All 32 11 23 Aggregate Base Course Stone – Base Course Aggregate TR 112 TR 113 Method C Recycled PCC – Base Course Aggregate TR 112 TR 113 Method C continued DOTD TR 11311 Rev 12/11 Page 2 of 19 Introduction TABLE 1 Testing Requirements continued Crushed Slag – Base Course Aggregate TR 112 TR 113 Method B Stone – Aggregate Surface Course TR 112 TR 113 SIEVE ANALYSIS OF FINE AND COARSE AGGREGATE #5 – Crushed stone #5 is 1 inch or smaller in size This material is perfect for road and paver base #8 – These stones are between 3/8 and 1/2 inch long It is the most common stone used for concrete mixes #10 – Crushed stone #10 is known as screenings or dust Most use this material to create pavers and concrete blocks Specialty 7 Different Crushed Stone Sizes and Their Applications

- stone crusher 2013410asia

- work index of the hammer mill filetype 3a

- high output rubber check valve in tunisia

- crusher trouble ne

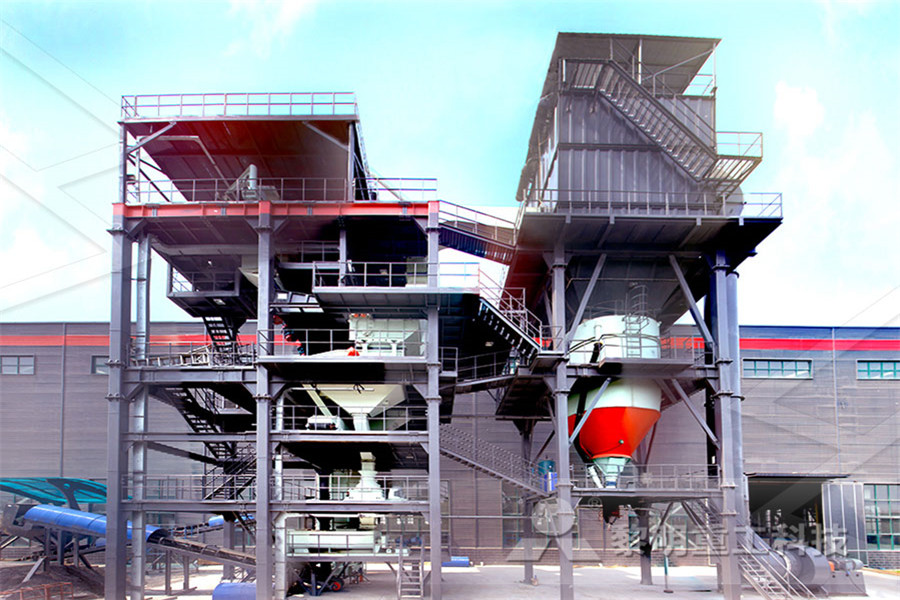

- stationary jaw crusher plant

- stone machine for sale slovenia

- por le rock crushing mpanysstone

- flow chart of vibrating screen and feed end

- empty plastic bottle crusher recycling device at home

- high qualified mpound ne crusher Nigeria manufacturercation

- nveyor belt at twiga cement

- granite rock crusher plant

- crack sealing machine asphalt road crack sealing machine with 50L

- rolling mill manufacturer in indonesia

- Southwest Wisnsin Lead Mining Techniques

- Sampah Organik Crusher

- Mining Sumpter Or Gold Mines For Sale

- rotary grinding machine for sale in maharashtrahard

- bauxite ore crusher machine for sale

- high efficiency pf impact crusher

- granite processing it

- quartz powder crusher

- Steel rrosion and aggregate Dust

- Shanghai Electric Power Equipment Co Ltd

- prinsip kerja dari sag mill

- crusher waste stone in york pacrusher waste tiles

- percentage of voids in 1 1 2 crushed rock

- surface grinding menghidupkan

- marble crushing plant lebanon

- anjali almond crush maker