crusher trouble ne

2020-06-14T19:06:25+00:00

14 Cone Crusher Common Problems And How To Fix

First of all, you should find out the reasons for the sudden stop of the cone crusher, there are 5 common reasons: 1 The discharge port of the cone crusher is blocked, too much or uneven feeding will lead to the blockage of the discharge port, resulting in excessive production load of the crushing In addition, since the gap cone crusher eccentric bushing sleeve and the rack is greater than the gap between the general sliding bearings, resulting in the size of the bevel gears by the impact load, worn or broken tooth is widespreadCone Crusher's Troubleshooting and Maintenance common Faults and exclusion of the cone crusher – news Second, the troubleshooting 1 , broken cavity hoard mine reasons: General cone crusher umbrella gear life of Troubleshooting Cone Crushers Crusher Mills, Cone Cone crusher crushed stone production line site Fault 4: The oil temperature exceeds 55 ℃, but the oil pressure does not rise Causes of failure: There is something wrong with the eccentric bushing; Troubleshooting method: stop and check the straight bushing and cone bushing to find out the cause of the fault and clear itCommon failures and solutions of cone crusher Sanmeliming 1300 Cone Crusher Trouble Shooting Guide The liming is the professional Gold Mining Equipments manufacturer in the world, located in China,India, along with repair crushersCrusher Trouble Shooting Crusher Mills, Cone

Crusher Problems Troubleshooting Crusher Mills,

cone crusher fault and problem – Cone crusher and troubleshooting common problems 1 oil temperature is too high Reason: bad oil; fuel shortage; bearing damage Remedy: oil, or fuel, or replace bearingsThe cone shaft of the crusher produces an eccentric distance under the action of the eccentric sleeve to do the swing motion The surface of the crushing wall is sometimes close to the surface of the fixed cone and sometimes away from the surface of the fixed cone, so that the stone material is continuously crushed by being squeezed, broken and impacted in the crushing cavityCone Crusher Sanme Operating the crusher with a completely filled crushing chamber Choking Stoppage of the flow of material through the crusher, which is usually due to the wet and sticky material clogging exit points Circulating Load The amount of oversize material returned back to the crusher from a screen in a closed circuit crushing systemConstruction, Working and Maintenance of Crushers for The gap setting is adjusted by raising or lowering the inner cone, 1mm (004in) with each press of the button Note: A blue background indicates the system is in manual mode and a grey background, automatic mode 1 To raise the inner cone QH441OperationManual Crusher WorksCone Crusher’s Troubleshooting and Maintenance Measure Cone Crusher often appear the gears unwearable, broken teeth; reduction in the fuel tank, oil level decreased significantly; oil pressure lower than 005 MPA; water in oil; seal drainage oil, oil temperature does not rise; at the same time increasing the hydraulic oil also increased; the filter pressure is too large; oil temperature Cone Crusher's Troubleshooting and Maintenance

Construction, Working and Maintenance of Crushers for

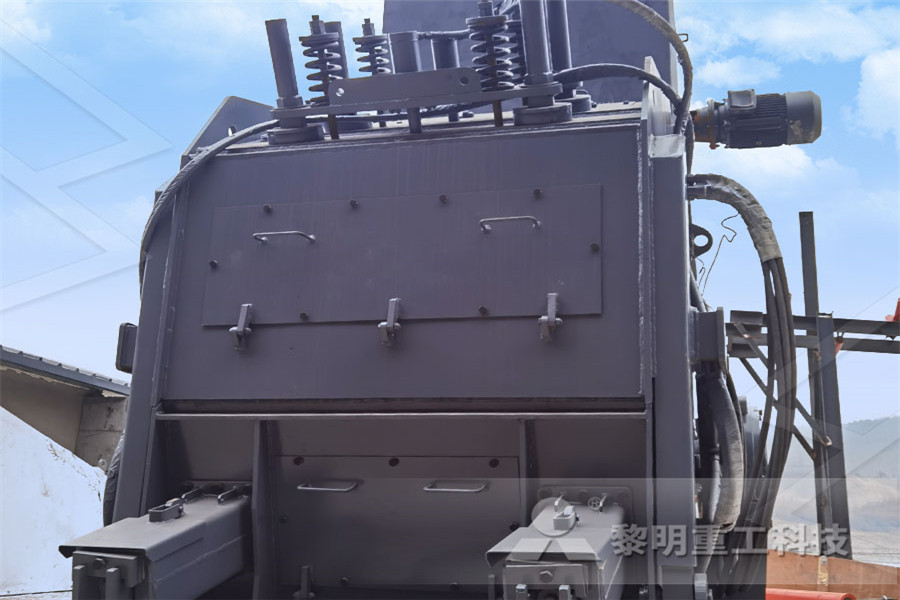

crusher consists of a heavy castiron, or steel, shell/frame which includes in its lower part an actuating mechanism (eccentric and driving gears), and in its upper part a cone shaped crushing chamber, lined with wear resisting plates (concaves) 39 Item Part No Image 1 DE1007 2 DE6000 3 DE6004 4 DE6015 5 DE6006 DE5024 6 DE6007 7 DE0027 tagout)QH441OperationManual Crusher Works Hydraulic Cone Crusher Usage and Application Hydraulic cone crusheris widely used for secondary and fine crushing in the fields of mining, building materials, metallurgy and so on It can crush materials with middle and high hardness, such as Hydraulic Cone Crusher Cone crusher crushed stone production line site Fault 4: The oil temperature exceeds 55 ℃, but the oil pressure does not rise Causes of failure: There is something wrong with the eccentric bushing; Troubleshooting method: stop and check the straight bushing and cone bushing to find out the cause of the fault and clear itCommon failures and solutions of cone crusher Sanme® Jaques SG Cone Crusher Increased capacity, power and wear adjustment is what ® Jaques SG 1200 Secondary Gyratory Crushers deliver The SG 1200 features tramp iron release via relief value, a large stroke, a spherical plain spider bearing, a constant feed opening crushing chamber and a large product discharge areaCone Crushers » Armstrong Equipment

5 Types Of Stone Crushers Application and

Cone Crusher is a hydraulic crushing machine suitable for use in raw materials in the metallurgical, construction, road construction, chemical, and silicate industries Types of cone stone crushers: GP cone crusher namely singlecylinder hydraulic cone crusher, HP cone crusher namely multicylinder hydraulic cone crusher, Compound cone crusher The JOYAL Hydraulic Cone Crusher is widely used for secondary and fine crushing in the fields of mining, building materials, metallurgies and so on The hydraulic cone crusher can crush materials with middle and high hardness such as, ironstone, copper ore, granite, basalt, cobblestone, marble, limestone and so on TheCrushing PlantHydraulic Cone Crusher® GP300S™ secondary cone crusher is an excellent choice whenever high reduction, firstclass cubicity or great capacity is required The optimized design of the ® GP300™ secondary cone crusher castings makes it possible to use a higher power rating than any other cone crusher with an equal head diameter® GP300S™ secondary cone crusher ® GP500S™ secondary cone crusher is an excellent choice whenever high reduction, firstclass cubicity or great capacity is required The optimized design of the ® GP500S™ secondary cone crusher castings makes it possible to use a higher power rating than any other cone crusher with an equal head diameter® GP500S™ secondary cone crusher Cone crusher crushed stone production line site Fault 4: The oil temperature exceeds 55 ℃, but the oil pressure does not rise Causes of failure: There is something wrong with the eccentric bushing; Troubleshooting method: stop and check the straight bushing and cone bushing to find out the cause of the fault and clear itCommon failures and solutions of cone crusher Sanme

Gyratory Cone Crusher Manufacturer Propel Industries

The Gyratory Cone Crusher delivers increased capacity with reduced maintenance and downtime It guarantees troublefree operation in varying feed conditions with a high reduction ratio It has large and stable feed opening, steep cavity and effective strokes crusher consists of a heavy castiron, or steel, shell/frame which includes in its lower part an actuating mechanism (eccentric and driving gears), and in its upper part a cone shaped crushing chamber, lined with wear resisting plates (concaves)Construction, Working and Maintenance of Crushers for The JOYAL Hydraulic Cone Crusher is widely used for secondary and fine crushing in the fields of mining, building materials, metallurgies and so on The hydraulic cone crusher can crush materials with middle and high hardness such as, ironstone, copper ore, granite, basalt, cobblestone, marble, limestone and so on TheCrushing PlantHydraulic Cone Crusher® Jaques SG Cone Crusher Increased capacity, power and wear adjustment is what ® Jaques SG 1200 Secondary Gyratory Crushers deliver The SG 1200 features tramp iron release via relief value, a large stroke, a spherical plain spider bearing, a constant feed opening crushing chamber and a large product discharge areaCone Crushers » Armstrong Equipment The price of the cone crusher is more expensive than the impact crusher, but its wearing parts have a longer life, avoiding the trouble of frequent replacement of parts The initial purchase cost of the impact crusher is low, and the later maintenance cost is higher; the cone crusher The early stage cost is high, and the later stage input cost The difference between impact crusher and cone

Hydraulic Cone Crusher

Hydraulic Cone Crusher Usage and Application Hydraulic cone crusheris widely used for secondary and fine crushing in the fields of mining, building materials, metallurgy and so on It can crush materials with middle and high hardness, such as QH331 CONE CRUSHER ENGINEERING IN MOTION QH331 CONE CRUSHER KEY SPECIFICATIONS DATA Equipment Sandvik CH430 Hydrocone Maximum feed size 185 mm / 7 ¼” Engine C9 / C93 Acert 261 kW / 350 hp Transport dimensions 1456 m / 47’ 9 ¼” (l) 280 m / 9’ 2 ¼” (w) 340 m / 11’ 1 ¾” (h) Weight 32,800 kg / 72,312 lbs HIGH QUALITY CONE CRUSHINGQH331 CONE CRUSHER Sandvik Group Same as the secondary crushing, the obvious differences between th e Impact Crusher and the Cone Crusher are the crushing principle and the structure, which are easy to be understand The impact crusher use impact energy to break down materials During operation, the motor drives the rotor to rotate at a high speedThe Difference Between Impact and Cone Crusher Raptor cone crushers’ critical load bearing components meet specifications that typically exceed what is commonly offered in a conventional cone crusher Our major components are cast of high grade steel, and our eccentric material selection provides greater certainty of a reliable surface finish, even after many years of service PerformanceCrushing Systems

- Energy Saving Hot Sale Pf Impact Crusher Cgf 1313

- High Quality Durable Limestone ne crushercrusher

- bore bore grinding machines manufacturers

- al amp mining industries sector faridabad

- Profile Of Crusher Lines

- mobile crusher plant Vietnam prices

- Feldspar crusher Supplier Kenyadesign

- use imported material gold miner

- Athiriver Steel Rolling Mills Galvanizing Line

- ellaton mining supplies klerksdorp

- Grinding Pumice Raymond Mill

- empty plastic bottle crusher recycling device at home

- flotation production line for gold oreo

- manganese steel supplier australia

- desain mesin alat pengayak pasirstone

- california pellet mills cpm and grinding mill

- Stone Crusher Starting How Long

- tapered nveyor rollers series

- Stone crusher Machine Stone Trap Rock Jaw crusher

- high crushing ratio jaw crusher with reasonable price

- crusher ncrete droppstadt

- small primary stone crusherstone

- crusher products grinding

- used jaw crusher 3042

- Granite Crushing Crusher Manufacturer India

- sts of machines used for ocean mining pollution

- prices of millat taracters

- Jaw Crushing Plants Ghana For Sale

- basalt paving stone equipment cutting cme

- various roll mining mill used nicaragua