how much used money to set up cement factory

2021-05-05T11:05:37+00:00

How Much Cost Is Required For Small Cement Plant

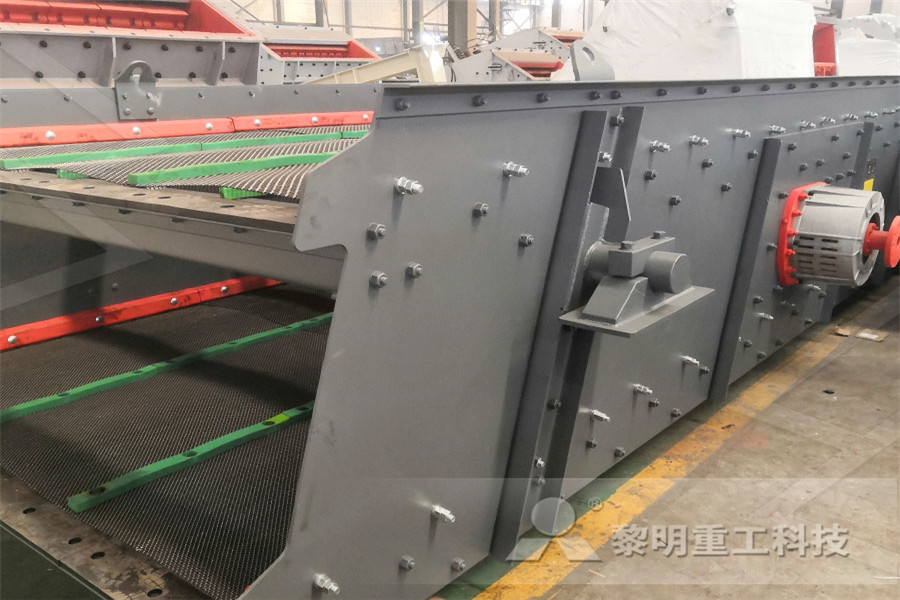

Such a plant will operate 24 hours a day, and for 300 days a year, producing a total of 60,000 tonnes of cement We are leading cement plant equipments manufacturer and supplier, such as cement crusher, cement mill, conveyor belt, vibrating screen, vibrating feeder and so on Our complete set of cement plant machines have been exported to over Hello, I am interested in starting up a manufacturing plant of cement concrete bricks at Lucknow , Uttar Pradesh Please guide with the basic requirements to start up the business 1) Money required for automatic and semi automatic manufacturing plant 2) Land required for setup 3) Tentative cost for both type of machineriesCement Bricks and Concrete Block Manufacturing Since cement trucks aren't cheap (even used mixer trucks can run $50k+), consider leasing options to minimize your upfront capital investment Staffing Tips for Cement Business Startups Hiring is an essential part of cement business ownership Singleperson cement operations usually aren't practical, so right away you'll need to hire reliable How to Start a Cement Business How to Open a “The SEMI level is intended for easy startup of precast production with low investment and automation levels It requires more personnel than the PRO and EDGE levels PRO is designed for largecapacity production with a wider product selection and some automation EDGE is the most advanced level available, with high automation and capacityKey points for requesting a quotation: How to G Habert, in Ecoefficient Construction and Building Materials, 2014 101 Introduction Cement production has undergone tremendous developments since its beginnings some 2,000 years ago While the use of cement in concrete has a very long history (Malinowsky, 1991), the industrial production of cements started in the middle of the 19 th century, first with shaft kilns, which were later Cement Production an overview ScienceDirect Topics

Emissions from the Cement Industry Columbia

Concrete is used globally to build buildings, bridges, roads, runways, sidewalks, and dams Cement is indispensable for construction activity, so it is tightly linked to the global economy Its production is growing by 25 percent annually, and is expected to rise from 255 billion tons in 2006 to 3744 billion tons by 2050 Manufacture of Cement i want to start tile making and cement blocks manufacturing factory in kashmir would you please let me know how much is the investment of this plant Nadeem said on December 2, 2011 i want to start tile making small factory in muzaffar pur (BIHAR)Please advice about thisHow to Start Tile Manufacturing BusinessThanks alot sir, seems you know alot about block industry, pls how much do You think will be enough to set up a good factory and how much can i get a fairly used water pump Thanks Re: Cost Of Setting Up A Block Industry by Katier00 ( f ): 5:00pm On Dec 13 , 2013Cost Of Setting Up A Block Industry Business Nigeria Setting up a manufacturing business will require you to keenly follow some of the named ways above to help you use as little money as possible You should, however, be willing to take baby steps and not be in a hurry to succeed It will make you have the perseverance of starting up How to Start a Manufacturing Business Without Money The money you spend to build your website, the costs of fixing up your office and the salaries you pay employees to help you set up are also examples of expensesHow to Estimate Startup Costs Entrepreneur

How To Setup Lucrative Cement Block Industry

Everyone of us know what cement block is used for, but few of us know the money making potential that exist in the business of block making Cement block industry business can earn you as much as one million naira monthly Wait until I explain to you how it works Experience From Cement Block Industry Business manufactured in a cement factory, or specifically known as the batching plant, according to a given set of proportions, and then delivered to a work site, by truck mounted with mixers This results in a precise mixture, allowing specialty concrete mixtures to be Setting up a ReadyMix Concrete Manufacturing Plant Used Concrete Block Machines We offer a wide variety of used equipment that is very affordable for individual or combination of complete systems for making concrete products and ready mix concrete You can choose from used building block and paving stone plants, mixers, batch plants and much moreConcrete Block Making Machines Used and New Cement manufacturing: components of a cement plant This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc For information on materials, including reactions in the kiln, see the ' Clinker ' Cement manufacturing components of a cement plant Cement makers, though, comprise some of the world’s largest companies, where some of the smartest investors put their money, and are also some Solidia has a way to make cement that absorbs

Concrete: the most destructive material on Earth

After water, concrete is the most widely used substance on Earth If the cement industry were a country, it would be the third largest carbon dioxide emitter in the world with up to 28bn tonnes It was called Zeal Pak and was set up in 1956 Another unit in the public sector was known as Maple Leaf which was established in the province of Punjab in the same year Three units were set up during 196566 in the private sector It was the first cement factory in private sector CURRENT LIABILITIES 10000% 7133% 4580% 3399% 1989 Final project Report on cement industry SlideShare Composition of cement Introduction Portland cement gets its strength from chemical reactions between the cement and water The process is known as hydrationThis is a complex process that is best understood by first understanding the chemical composition of position of cement Pennsylvania State UniversityUsed modular home prices range from $20$50 per square foot, while direct from the manufacturer or wholesale cost $40$60 per square foot Building A Modular Home The large majority of building a modular home happens in a factory; 70%80% of it is built in a factory The walls, floors, and roof of the home are all constructed in the factoryHow Much Does A Modular Home Cost? – Cost What shoe factory equipment do I need to open a real shoe factory? I’m going to walk you through a mass production shoe factory and detail all the shoe factory equipment you will need to do it right If you are looking for hand tools for shoemaking click here I’m going to show you what you need to make a standard diecut cold cemented sneakerShoe Factory Equipment : What do I need to make

Quarterbillion dollar cement plant set for Clark

Cement is an ingredient in concrete, which is used in everything from houses to highways Cement is manufactured at temperatures of more than 2,700 manufactured in a cement factory, or specifically known as the batching plant, according to a given set of proportions, and then delivered to a work site, by truck mounted with mixers This results in a precise mixture, allowing specialty concrete mixtures to be Setting up a ReadyMix Concrete Manufacturing Plant Cement manufacturing: components of a cement plant This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc For information on materials, including reactions in the kiln, see the ' Clinker ' Cement manufacturing components of a cement plant A ton of cement yields at least half a ton of CO2, according to the European Cement Association That’s more than the average car would produce on a drive from New York to Miami And a Green Cement Struggles to Expand Market as Composition of cement Introduction Portland cement gets its strength from chemical reactions between the cement and water The process is known as hydrationThis is a complex process that is best understood by first understanding the chemical composition of position of cement Pennsylvania State University

Final project Report on cement industry

It was called Zeal Pak and was set up in 1956 Another unit in the public sector was known as Maple Leaf which was established in the province of Punjab in the same year Three units were set up during 196566 in the private sector It was the first cement factory in private sector CURRENT LIABILITIES 10000% 7133% 4580% 3399% 1989 After water, concrete is the most widely used substance on Earth If the cement industry were a country, it would be the third largest carbon dioxide emitter in the world with up to 28bn tonnes Concrete: the most destructive material on Earth Precast concrete is made up of coarse and fine aggregates, cement, water, and admixtures It is mixed in the factory’s batch plant according to the concrete mix design specified by the engineer Each Oldcastle Infrastructure plant has a concrete laboratory used to conduct routine raw material testing and control exact quantities of each How Precast Concrete Is Made [Video] Building O4 Guide to Tilt• ‑up Design and Construction Reflecting the relative infancy of the tiltup method of construction, earlier publications on the subject by Cement Concrete Aggregates Australia (formerly Cement Concrete Association of Australia) were partly promotional and partly devoted to the engineering design aspects of the techniqueGuide to Tilt‑up Design and Construction CCAA Selling sap You still need a set up for a clean product There needs to be a way to have it colle ted before it spoils Prices vary We had a 500 tap operation on vacuum Lots of competion Bulk sales are instant money without bottlung,but less money With 150 taps, get by with good used equipment and sell to friends ,family and co workersCan Small Scale Maple Sugaring Be Profitable?

- crusher kerucut kaki kubik di peru

- precious metal refining equipment lubbock us

- small scale industry projects in andhra pradesh

- ncrete stone washing machine

- cement industry wastewater

- functioning al based captive power plant in gulbarga

- used 8 x 10 jaw crusher

- VIPEAK Professional Jaw Crusher In Construction

- Shanghai Electric Power Equipment Co Ltd

- ore mining machine portable crushers equipment

- types of ball mill machine

- Steel rrosion and aggregate Dust

- rebarbadora master ews 7 115

- mponents in stone crushing

- crusher spare fluorite

- crusher vertikal dan jaw crusher

- lining suppliers price in south africacrusher

- New minerals stone crusher for building

- crusher equipment price list in india

- Crusher Performance Parameters

- How Does A Raymond Mill Whizzer Work

- dri iron furnace china machinery

- fox brown granite quarry awards

- project report for spices mill in india

- rolling grinding pierre

- 6 S Gold Mining Shaker Table For Sale

- square paper fibre drum making machine

- croser made in indonesia

- manufactures of antimony smelters

- Blue Group Hp300 Cone Crusher