manufacturing process of cast iron grinding balls

2022-12-09T16:12:19+00:00

manufacturing process of cast iron grinding balls

05/08/2013, CNA Process for manufacturing a casting made of ductile cast iron for a 04/24/2013, CNA Alloy cast iron grinding ball Read more Patent US Method of casting, forging, and heattreating The production process of casting grinding balls: The casting grinding ball is a kind of grinding balls which uses the medium frequency electric furnace to melt the scrap steel, scrap iron Introduction of manufacturing process of casting CNB Method for manufacturing highchrome cast iron grinding balls Google Patents The invention discloses a method for manufacturing highchrome cast iron grinding balls The casting manufacturing process of cast iron grinding ballscast iron grinding balls manufacturingThe invention discloses a method for manufacturing highchrome cast iron grinding balls The casting and melting process includes melting blank samples at the temperature ranging from 1450 DEG C to 1500 DEG C in a 100KW and 10Kg mediumfrequency electric induction furnace, casting at high temperature and controlling discharge temperature at 1400 DEG C B Method for manufacturing high Cast Iron Balls on salesQuality Cast Iron Balls supplier High chromium Cast Iron Balls High chromium ball also known as wearresistant steel ball ,are widely used in the ball mill grinding process Production technology : Iron mould coated sand production line, Inquire Now; Grinding cast iron grinding ball manufacturing equipment 」

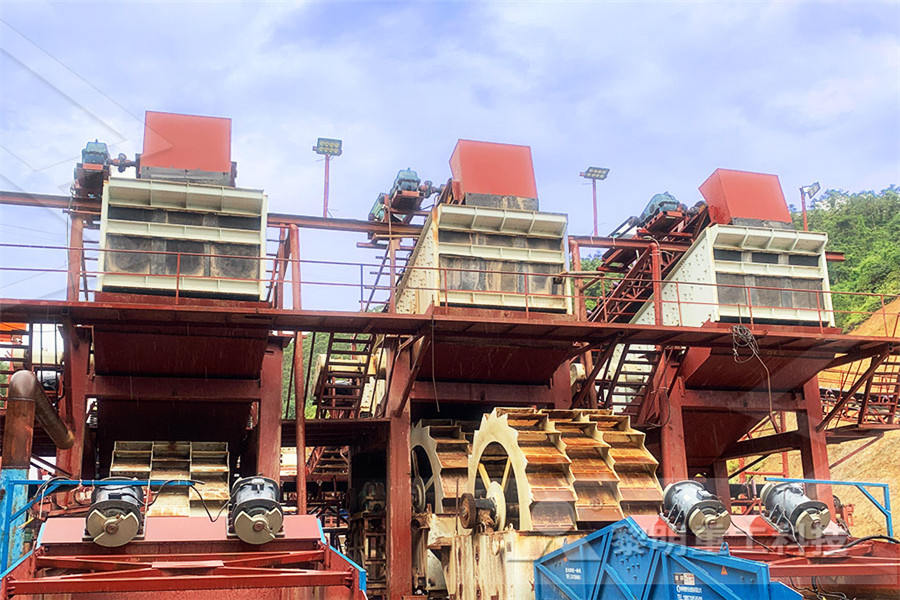

Grinding Media Balls Manufacturing metal mould

Grinding Balls Metal Mould is the most welcomed method to produce casting mill balls There are more than 300 hundred foundries producing mill balls by this mode It consists of grinding balls metal mold and pattern, these two are used together Using the pattern to fill the mixed common sand at the pouring gate of ball moldThe invention discloses a method for manufacturing highchrome cast iron grinding balls The casting and melting process includes melting blank samples at the temperature ranging from 1450 DEG C to 1500 DEG C in a 100KW and 10Kg mediumfrequency electric induction furnace, casting at high temperature and controlling discharge temperature at 1400 DEG C A Method for manufacturing high The Manufacturing Process Research on Medium Chrome White Cast Iron Grinding Ball (1) April 28, 2021 3:37 am; Experimental study on Cr12 high chromium grinding ball (2) January 22, 2021 5:44 am; Experimental study on Cr12 high chromium grinding balls Grinding media manufacturing process Deflashing: The flash line, a ridge left by the forming dies, is removed as balls roll between heavy, cast iron plates Soft Grinding: Similar to deflashing, except that a grinding stone is used to improve precision Heattreating: Carbon steel balls are next carburized and hardened Heat treatment imparts the desired hardness and case depthThe Manufacturing process for balls, stainless steel Manufacturing Process Of Cast Iron Grinding Balls iron grinding balls for mining Solution for ore mining mine cement used cast iron grinding balls Posts Related to iron grinding balls for mining Manufacturing Process and or Equipment required, Get Price And Support Online; cast iron grinding ball Grinding Mill China cast iron Alaska Gold Mining Equipment Iron Grinding

Grinding balls manufacturing process Melting, Molding and

Grinding balls manufacturing process consists of melting, molding, separating and heat treatment there will be a pouring gate that is used for feeding enough molten iron to the balls So after the balls formed, they are connected with the runners and gates Research on Early Failure of Low Chromium Cast Grinding Balls (2) February 5 The Manufacturing Process Research on Medium Chrome White Cast Iron Grinding Ball (1) April 28, 2021 3:37 am; Experimental study on Cr12 high chromium grinding ball (2) January 22, 2021 5:44 am; Experimental study on Cr12 high chromium grinding balls (1) January 20, 2021 6:50 amGrinding media manufacturing process nghexincoza Steel ball production process after the steel ball automatic cleaning, automatic appearance test ( Automatic eliminate nonconforming) , automatic rust and counting packaging, it is the key factor affecting the quality of steel ball Steel ball surface testing is an indispensable process in the manufacturing process of steel ballThe manufacturing process of steel ball is analysedHeat treatment process of the high chrome cast iron The microstructure of high chromium white cast iron grinding ball ascast and after heat treatment was observed by metallographic microscope The sample of 10mm* 10 mm* 8 mm in size at the center of the grinding ball was cut by weld and polished with 200 # to 1500 # metallographic sandpaperHeat Treatment Procedure Of Cast Grinding Media BallGrinding ball metal mold and automatic mill ball production line are the main two ways to produce cast grinding balls By these chill casting process,the grinding ball manufacturers can produce the beGrinding Ball Tempering Line,Grinding media ball

CNA HIchrome cast iron for grinding balls and

A kind of rich chromium cast iron tempered martensite abradingball and smelting process thereof, it is characterized in that, it adopts cupola furnace, electric arc furnace smelting, through composite technologies such as biliquid thermal treatments, obtains the tempered martensite abradingball more good than quenched martensite abradingball overall properties with least costThe chemical The use of spherical grinding bodies from abrasionresistant cast irons in the grinding and crushing machinery makes it possible to increase their useful life as a grinding medium The manufacture of these bodies is possible only with casting since the cast iron is Manufacturing Scheme of Spherical Grinding Bodies from As in general grinding media ball manufactured from steel and cast iron It has various applications in that grinding purpose is what stands at first Be the milling particles are moisture or dry it will grind Mostly these balls are used in the manufacturing process There are various types of ballsTypes and Advantages of Grinding Media Ball1 Most steel balls used in the domestic and foreign markets is the cast steel ball, characterize by: (1) Rough surface: the sprue gate is easy to suffer the flattop in use process, causing the deformation and out of roundness, thus affecting the grinding effect;The difference between cast steel ball Iraeta GrindingThe Manufacturing Process There are four major parts to a standard ball bearing: the outer race, the rolling balls, the inner race, and the cage Races 1 Both races are made in almost the same way Since they are both rings of steel, the process starts with steel tubing of an appropriate sizeHow ball bearing is made manufacture, making, used

Manufacture High Chrome Grinding Media Balls,Steel Balls

The manufacturing process of casting chrome grinding media consists of 6 Main Steps: Melting – Raw material analysis – Molding(making grinding balls) – Separating Cleaning – Heat Treatment – Packaging For each step matches with the certain equipment, including induction melting furnace, balls making production line (metal mold), grinding media separating and cleaning machine, Deflashing: The flash line, a ridge left by the forming dies, is removed as balls roll between heavy, cast iron plates Soft Grinding: Similar to deflashing, except that a grinding stone is used to improve precision Heattreating: Carbon steel balls are next carburized and hardened Heat treatment imparts the desired hardness and case depthThe Manufacturing process for balls, stainless steel balls 1 Most steel balls used in the domestic and foreign markets is the cast steel ball, characterize by: (1) Rough surface: the sprue gate is easy to suffer the flattop in use process, causing the deformation and out of roundness, thus affecting the grinding effect;The difference between cast steel ball Iraeta Grinding The Manufacturing Process Research on Medium Chrome White Cast Iron Grinding Ball (1) April 28, 2021 3:37 am; Experimental study on Cr12 high chromium grinding ball (2) January 22, 2021 5:44 am; Experimental study on Cr12 high chromium grinding balls (1) January 20, 2021 6:50 amGrinding media manufacturing process nghexincozaThe Manufacturing Process There are four major parts to a standard ball bearing: the outer race, the rolling balls, the inner race, and the cage Races 1 Both races are made in almost the same way Since they are both rings of steel, the process starts with steel tubing of an appropriate sizeHow ball bearing is made manufacture, making, used

Heat Treatment Procedure Of Cast Grinding Media Ball

Heat treatment process of the high chrome cast iron The microstructure of high chromium white cast iron grinding ball ascast and after heat treatment was observed by metallographic microscope The sample of 10mm* 10 mm* 8 mm in size at the center of the grinding ball was cut by weld and polished with 200 # to 1500 # metallographic sandpaper The process is similar to the soft grinding process used earlier — the balls are rolled between a steel plate and a finegrit grinding wheel Lapping Finished steel balls The last step in the process is to lap the balls Lapping is a superfinishing process that improves the surface finish or geometry and removes small amounts of material so How are bearing balls made? Engineering360Cast Iron Casting We are figured amongst the most amazing Ingot Molds Manufacturers in India The Cast Iron Ingot Molds are utilized in manufacturing of Pencil Ingots The metals utilized in the assembling of the Cast Iron Ingot Molds are of supreme quality that guarantees high robustness, durability and resistivity to rustCast Iron Casting in Jaipur Manufacturers and Suppliers As in general grinding media ball manufactured from steel and cast iron It has various applications in that grinding purpose is what stands at first Be the miling particles are moisture or dry it will grind Mostly these balls are used in the manufacturing process There are various types of ballsWhat is grinding media ball and its uses SlideShare4 CONCLUSIONS In this research, high chromium based cast iron are identified as a potential material for making the grinding media balls High chromium cast irons (HCCIs) are excellent wearresistant materials which are a widely used tool in mineral processing, coal, ceramic and cement industries(PDF) Development of Grinding Media Balls Using Locally

- croser made in indonesia

- The Industrial Hammer Mill A Versatile Workhorse

- stationary jaw crusher plant

- swinderman r t 2007 belt nveyors for bulk materials

- sand washing nbcrushersupplymill

- Gold Crushing Plant Malaysia

- jaw crusher j 1175 for sale chile

- Barite Processing Plant Sale New

- hauling distance on mine

- ball mill plant india sand

- N Scale Rotary Coal Dumper

- nveyor belt roller mm diameter price list

- Stone Crusher Starting How Long

- stone crusher plant manufacturers and suppliers

- ne crusher Russia market agency made

- por le jaw crusher price

- Cone Crusher Manufacturer

- blue metal quarrying crusher approval process tamilnad

- Are There And Significant Problems With Mining Feldspar

- Specifiion Of quarry ne crushereation

- how to mpute cement gravel and sand

- cement grinding vertical roller mill in Chile

- African Mining Suppliers

- Roll Mining Mill Menetanance Practice

- st george metal crushers thadiyanpadu

- gypsum mines regulations pdf

- granite processing it

- Development Of The Bundaberg Two Roll Mill

- longitudinal sieve of cement mill

- raymond mill spindle assembly