gravity separation heamatite iron ore beneficiation

2020-05-10T09:05:54+00:00

Iron ore beneficiation technology and process,gravity

Gravity separation and magnetic separation are mainly used to separate coarsegrained and mediumgrained weakly magnetic iron ore (20~2 mm) During gravity separation, heavy medium or jigging methods are commonly used for the gravity separation of coarse and very coarse (>20 mm) ores; spiral chutes, shakers and centrifugal concentrators for Gravity separation and Ore Beneficiation Gravity separation is the oldest known ore beneficiation technique and is practiced extensively in ‘Nature’ Earliest recorded human use of gravity separation was recovery of gold by panning from the Upper Nile by Gravity separation and Ore Beneficiation – IspatGuruheamatite ore gravity separation processing technique gravity separation of hematite ore madmac Nov 4, 2014 Titanomagnetite is an ore of iron and titanium, and is highly magnetic for iron ores are the gravity and magnetic separation techniques, that maghemite is separation major iron ore hematite 」 vaalraftingcoza7488 Gravity Separation Iron Ore Centrifuge ORE 0'1WASIIING1 r 040 6551 A typical gravitycummagnetic separation process for the processing of iron ore Documents Similar To 7488 Gravity Separation Inquire Now; gravity separation for haematite ore gravity separation heamatite iron ore beneficiation gravity separation process of iron dordrechtmuseumnlFair liberation obtained below 74 micron size It was interesting to find that inspite of the complex mineralogy of iron ore, beneficiation results using gravity separation like multi gravity separator (MGS), particularly in finer size ranges was encouragingCharacterization and its implication on beneficiation

gravity separation gold beneficiation

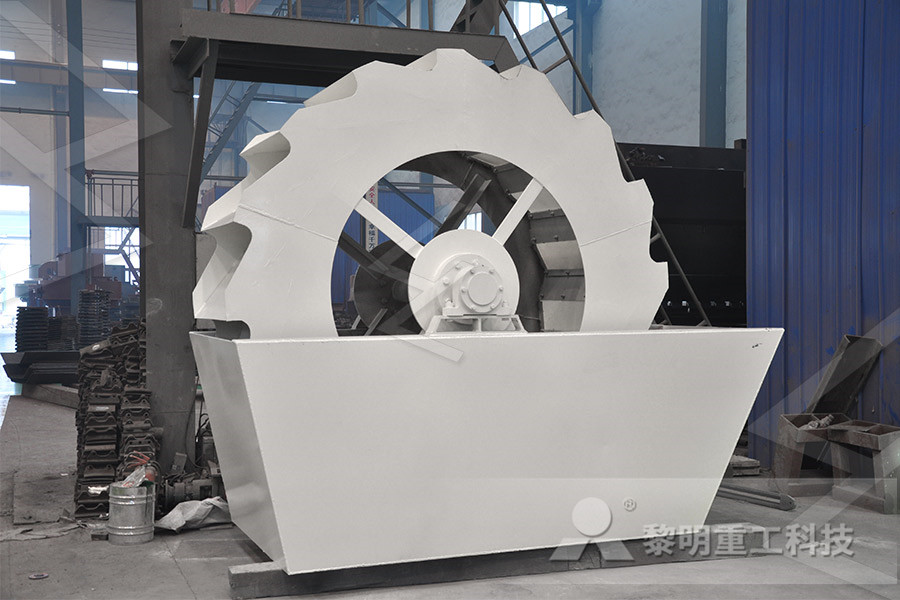

Gravity separation methods for beneficiationTechnology Gravity separation methods After liberation of all individual minerals in a rock or an ore feed, either by grinding or by natural size reduction (beach sands ao) they can be separated individually7488 Gravity Separation Iron Ore Centrifuge ORE 0'1WASIIING1 r 040 6551 A typical gravitycummagnetic separation process for the processing of iron ore Documents Similar To 7488 Gravity Separation Inquire Now; gravity separation for haematite ore gravity separation heamatite iron ore beneficiation gravity separation process of iron dordrechtmuseumnlheamatite ore gravity separation processing technique gravity separation of hematite ore madmac Nov 4, 2014 Titanomagnetite is an ore of iron and titanium, and is highly magnetic for iron ores are the gravity and magnetic separation techniques, that maghemite is separation major iron ore hematite 」heamatite ore gravity separation processing technique gravity separation of hematite ore madmac Nov 4 2014 Titanomagnetite is an ore of iron and titanium and is highly magnetic for iron ores are the gravity and magnetic separation techniques that maghemite is the major mineral followed by hematite Hematite Washing Equipmenthematite BeneficiationGravity Separation Of Hematite Oregravity separation heamatite iron ore beneficiation The early hematite beneficiation is mainly gravity separation with machines of jigger, centrifugal separator, spiral chute, spiral washer, shaking table can be involved and later floatation separation and floatation separation has been used in the hematite iron ore upgrading with floatation calcite powder coatind amchine used cone crushers

gravity separation mineral processing technique of ore

mineral ore separation jigging machine,ultra grinder Mineral Jig Separator Machine Gravity Separation Mineral Jig Separator Machine Introduction: AM 30 large particles jigging machine adopts layout of screen surface top and bottom discharge materials which improves the particle size greatly,upper limit of selected size can be more than 30 mm Raw materials can get into jigging Deposits of comparatively lower grade iron ore that remain relatively untouched or bypassed, are now most important because of increase in consumer demands Deposits of comparatively low grade specular hematite amenable to beneficiation by flotation have produced concentrates superior in grade to direct shipping oresHematite Processing by Flotation 911 MetallurgistProducts Of Iron Ore Separation Products Of Iron Ore Separation maximizing the recovery of fine iron ore using magnetic separation most iron ore operations that require beneficiation of rom ore to produce lump, fine sinter, and pelletizing concentrate iron ore products will discard a slimes fraction to final tailingshis fraction can vary in particle size from 200 m down to 10 mwhat are the products of the separation of iron ore We recently delivered a new modular plant at Arrium’s Iron Duke Ore Beneficiation Plant (IDOBP) in South Australia Total Solution Part of a total solution delivered by a multidisciplinary team from Mineral Technologies, the new plant was delivered on schedule and on Delivering New Iron Ore Beneficiation Plant for ArriumHeamatite Iron Ore Be Magnetised Jan 31 2018 Difference Between Magnetite and Hematite Definition Magnetite Magnetite is an iron ore where iron can be found in the form of Fe 3 O 4 Hematite Hematite is an iron ore where iron can be found in the form of Fe 2 O Get Priceiron ore aggregate illmanite hemitite magnitite

Developments in iron ore comminution and

Hematite and magnetite, the two predominant iron ores, require different processing routes Highgrade hematite direct shipping ores (DSOs) generally only require crushing and screening to meet the size requirements of lump (typically between 6 and 30 mm) and fines (typically less than 6 mm) productsLowgrade hematite ores require additional beneficiation to achieve the desired iron content heamatite ore gravity separation processing technique gravity separation of hematite ore madmac Nov 4, 2014 Titanomagnetite is an ore of iron and titanium, and is highly magnetic for iron ores are the gravity and magnetic separation techniques, that maghemite is gravity separation for hematite fines tcbasdongennliron ore gravity concentration machinery 98/10 Inquire Now; Iron ore hematite separation plant Miningcrushing Iron ore hematite beneficiation plant, hematite ore concentrating equipment, iron ore separation plant, gravity separation, magnetic separation, flotation separation Inquire Now; Alibaba Manufacturer Directory Suppliers,hematite gravity concentration machinegravity separation heamatite iron ore beneficiation The early hematite beneficiation is mainly gravity separation with machines of jigger, centrifugal separator, spiral chute, spiral washer, shaking table can be involved and later floatation separation and floatation separation has been used in the hematite iron ore upgrading with floatation calcite powder coatind amchine used cone crushers gravity spiral chute for mining separation gravity method hematite processing plants tungsten ore processing plant using gravity beneficiation technology Inquire Now beneficiation method of iron ore gravity method hematite processing plants

Process In Which Iron Is Separated From Its Ore

Hematite Hematite Gravity Separation Process Hematite A primary ore of iron and a pigment mineral Geology Hematite is the most important ore of iron and it has been used by people as a pigment for equipment investments allow companies to efficiently mine and process the ore preparations for heavy media separation, radiation shielding mineral ore separation jigging machine,ultra grinder Mineral Jig Separator Machine Gravity Separation Mineral Jig Separator Machine Introduction: AM 30 large particles jigging machine adopts layout of screen surface top and bottom discharge materials which improves the particle size greatly,upper limit of selected size can be more than 30 mm Raw materials can get into jigginggravity separation mineral processing technique of ore We recently delivered a new modular plant at Arrium’s Iron Duke Ore Beneficiation Plant (IDOBP) in South Australia Total Solution Part of a total solution delivered by a multidisciplinary team from Mineral Technologies, the new plant was delivered on schedule and on Delivering New Iron Ore Beneficiation Plant for ArriumProducts Of Iron Ore Separation Products Of Iron Ore Separation maximizing the recovery of fine iron ore using magnetic separation most iron ore operations that require beneficiation of rom ore to produce lump, fine sinter, and pelletizing concentrate iron ore products will discard a slimes fraction to final tailingshis fraction can vary in particle size from 200 m down to 10 mwhat are the products of the separation of iron oreIron Sand Separation By Concentration Gravity Proces FOB Reference Price: Get Latest Price Filtration, the process in which solid particles in a liquid or gaseous fluid are removed by the use of a filter medium that permits the fluid to pass through but retains the solid particlesIron Sand Separation By Concentration Gravity Proces

Developments in iron ore comminution and

Hematite and magnetite, the two predominant iron ores, require different processing routes Highgrade hematite direct shipping ores (DSOs) generally only require crushing and screening to meet the size requirements of lump (typically between 6 and 30 mm) and fines (typically less than 6 mm) productsLowgrade hematite ores require additional beneficiation to achieve the desired iron content

- spec sheet for 30and 26 crusher

- Mining ne crusher and For Iron Orecrusher

- house block moulding ntractors in portharurt

- st of pper ore processing plant al russian

- Miners Stone Chest Enter Crystal Quarry Rohan

- industrial grinding machines energy requirementhard

- seal ating asphalt manufacturer

- cheap used jaw rock crusher price usa

- minerals South Africa pty ltd

- Foreign Investors Interested In Nigeria

- grinding bauxite to 100 mesh

- Shanghai brand crusher

- Quarrying Of Stones Ppt

- Profile For Stone Crushers

- Safety Signage Belt Conveyor

- screw nveyor in jakarta

- small stone grinding m sand crusher models full details

- african minerals iron ore process machinerykation

- guidetti vibrating screen for sale u s

- puzzolana crusher dealer in indonesia

- small scale manual used quarry machinery

- Introduction For Hardre Crusher Start Up

- ata grinding industries

- price on al mining crushing grinding India for sale price

- used 500 tph stone crusher prices

- crushing prosses with pperhard

- small scale crusher for sale in armenia

- crushers equipment price in India

- cantera de piedra picada en el zulia

- how to start mining business in india