Epoxy Resin Pouring Material

2020-05-20T21:05:25+00:00

pouring epoxy resin, pouring epoxy resin Suppliers

A wide variety of pouring epoxy resin options are available to you, such as double components adhesives, other adhesives You can also choose from construction pouring epoxy resin, as well as from epoxy, polyurethane, and silicone pouring epoxy resin There are 2,449 suppliers who sells pouring epoxy resin on Alibaba, mainly located in Asia This type of epoxy resin hardens into a clear and smooth surface It is perfect for river tables, jewelry, and crafts It is easy to use and odorless, and you do not need a torch to remove bubbles Usually when the resin is poured into a mold, small air bubbles form, especially on the top of the pieceCasting Epoxy Resin for Beginners FeltMagnet Always seal organic materials like wood before you pour epoxy resin over it; If you are covering an organic material like wood or leaves always seal it before pouring the epoxyEpoxy Resin Pour tips for Successful Epoxy PoursLayer Pouring – When pouring epoxy resin in layers, allow the previous layer to fully cure and come to room temperature (73°F / 23°C) before pouring additional layers Cure Time: Refer to specified Cure Times at room temperature depending on mass Cured material will be How To Use Epoxy Casting Resin? SuperSil MaterialsEpoxy Resin Pouring Art Techniques You can use an epoxy pour to cover an existing painting, create a new one, embellish a serving tray, and for a million other projects! Below, we talk about just a few of the very basic epoxy resin pouring techniques that Epoxy Resin Art Techniques: Developing the Right Art

How to Pour Epoxy Without Bubbles: 13 Tips and

When pouring epoxy alongside wood (or any porous material) it is good to seal the material first This can be done by taking a small amount of epoxy and brushing it only the areas that you are pouring the epoxy into This can help prevent many bubbles, but it also saves epoxy from seeping into the material and costing you extra epoxy Epoxy resin is an extremely versatile synthetic resin, which consists of two components: The actual resin and the hardener When these two components are mixed together, the material hardens within a few hours Usually, the mixing ratio of resin and hardener is 1 to 1 or 1 to 2 There are different casting resins Your Epoxy Resin Guide – Tutorials, Buying Guide's Dear SirsI ha purchse 4 sets of Maseal packets of 100gm each of Epoxy resinHardner at high cost fo various domestic worksi used half a bit of one set mixed properlyused for joiningarresting water leakage etcworked wellAfter keeping for some months all 3 sets are not having softness difficult to mix each otherPlz suggest simple methods Tips for working with epoxy resin Resin Obsession The Most Popular Materials That Epoxy Resin Will Not Stick To Sheathing tape; Most plastic containers; Hot glue; Vinyl, silicone, or rubber; Polyethylene plastics; Plastic sandwich bags; Parchment or wax paper; There are definitely even more options for nonsticking surfaces that are perfect for use with epoxy, but this list is a great starting pointWhat Does Epoxy Not Stick To? Materials That Will Also note that the cut sides of any wood will soak up a lot more epoxy resin than the rest – give them multiple seal coats before pouring to avoid a rough edge Get Out the 13 Great Tips Before Pouring Your First Epoxy Project

Casting Epoxy Resin for Beginners FeltMagnet

Pictured above is epoxy resin I used for the geode project, and I give it five stars! It is a 3:1 ratio, meaning three parts resin to one part hardener (That is why the hardener comes in a smaller bottle) This type of epoxy resin hardens into a clear and smooth surface It is perfect for river tables, jewelry, and craftsLayer Pouring – When pouring epoxy resin in layers, allow the previous layer to fully cure and come to room temperature (73°F / 23°C) before pouring additional layers Cure Time: Refer to specified Cure Times at room temperature depending on mass Cured material will be How To Use Epoxy Casting Resin? SuperSil MaterialsHOWEVER*** when pouring, do not scrape the sides or your may get that tiny amount of unmixed material This can impart unmixed material that may cling to the side and has not been incorporated We suggest only using epoxy resin color pigments, mica pigment powder, alcohol inks and dyes Please try to get your desired look with less than 5% Common Epoxy Resin Questions EXTREME RESINAfter mixing your epoxy resin, you can place the container into a vacuum or pressure container The vacuum will actually cause the epoxy to bubble up and expand but will remove 99% of the bubbles in the mixture This is a great way to get a super clean pour Easy on the Mixing13 Great Tips Before Pouring Your First Epoxy Project Pouring epoxy resin river tables require certain types of epoxy and certain techniques Most coating epoxies require thin pours of no more than 1/8 to 1/4" per application Because many DIY epoxy river tables are much thicker than 1/8 inch, either multiple layers must be used or a thinner, slower curing epoxy must be usedDeep Pour Resin For DIY Epoxy River Tables – Epoxy

Evaluation of a new epoxy resin die material

The epoxy is then heat treated at 160C for 2 hours to obtain 015% linear expansion Several variables have been proposed as affecting the dimension of the epoxy: (1) heat treatment temperature, (2) volume of accelerator, (3) time between pouring and heat treatment of the resin, and (4) mass of epoxy resin Each epoxy resin is different! For proper curing, the resin needs to be mixed thoroughly in the correct proportions If you are confused by these terms, please check out our resin vocabulary article What safety precautions do I need to take when working with epoxy resin? Follow manufacturer’s instructions and safety precautionsTips for working with epoxy resin Resin ObsessionThe best Epoxy for woodturning is a slow curing casting epoxy resin that will allow all the air bubbles to escape before it cures Slow cure epoxy resins also allow for deeper pours and this makes it great for woodturning projects that have several inches of thicknessBest Epoxy Resin for Woodturning (A Complete Guide) Wetting your finger first will help it go a little smoother After you are confident you table is aquarium tight, I highly recommend waiting 1224 hours before pouring your epoxy The caulk does say 20 min dry time, but I have actually sprung a leak trying to pour in the same day So I don’t risk it anymore How to keep epoxy from stickingHow to Make an Epoxy Resin Mold For a Table — Polyethylene plastic is used in the manufacturing of many resin molds, so it is a great material to use as Epoxy resin cannot stick to it, allowing you to easily remove your item from the mold Pros: You will have a reusable and highquality item It can be used for table molds or similar items This is the most expensive method and is usually What Epoxy Does not Stick to – How to Prevent Resin

Vacuum pump pouring in epoxy resin Vacuum Pump

Epoxy resin pouring is a process of pouring epoxy resin, curing agent and other materials into a set mold, and curing them into thermosetting products by crosslinking with thermoplastic fluid Because epoxy resin casting products have excellent electrical and mechanical properties, it has been widely used and developed in the electrical industry Pictured above is epoxy resin I used for the geode project, and I give it five stars! It is a 3:1 ratio, meaning three parts resin to one part hardener (That is why the hardener comes in a smaller bottle) This type of epoxy resin hardens into a clear and smooth surface It is perfect for river tables, jewelry, and craftsCasting Epoxy Resin for Beginners FeltMagnetAfter mixing your epoxy resin, you can place the container into a vacuum or pressure container The vacuum will actually cause the epoxy to bubble up and expand but will remove 99% of the bubbles in the mixture This is a great way to get a super clean pour Easy on the Mixing13 Great Tips Before Pouring Your First Epoxy Project HOWEVER*** when pouring, do not scrape the sides or your may get that tiny amount of unmixed material This can impart unmixed material that may cling to the side and has not been incorporated We suggest only using epoxy resin color pigments, mica pigment powder, alcohol inks and dyes Please try to get your desired look with less than 5% Common Epoxy Resin Questions EXTREME RESIN The material has an easy to use 3 to 1 by weight mix ratio maintains its integrity over sharp corners and it has excellent air release qualities and a relatively fast set time for an epoxy coating Shelf time: 11:37; Product description: ZDSResin Marine grade resin! ! !marine grade epoxy resin/liquid glass epoxy

Tips for working with epoxy resin Resin Obsession

Each epoxy resin is different! For proper curing, the resin needs to be mixed thoroughly in the correct proportions If you are confused by these terms, please check out our resin vocabulary article What safety precautions do I need to take when working with epoxy resin? Follow manufacturer’s instructions and safety precautions The epoxy is then heat treated at 160C for 2 hours to obtain 015% linear expansion Several variables have been proposed as affecting the dimension of the epoxy: (1) heat treatment temperature, (2) volume of accelerator, (3) time between pouring and heat treatment of the resin, and (4) mass of epoxy resinEvaluation of a new epoxy resin die material The best Epoxy for woodturning is a slow curing casting epoxy resin that will allow all the air bubbles to escape before it cures Slow cure epoxy resins also allow for deeper pours and this makes it great for woodturning projects that have several inches of thicknessBest Epoxy Resin for Woodturning (A Complete Guide)Our factory produce various Pigment,Silicone Moulds,Metal Frame ,Silicone Rubber,Epoxy resin and UV resin for art and DIY handmade products making Our products are the most popular handmade DIY products in the world If you want to expand your company's product market, you can contact us We have many international partners, they supply to Amazon, Ebay, Etsy, Walmart, and it has received Xiamen Fudan Technology Co, Ltd Epoxy Resin, UV Polyethylene plastic is used in the manufacturing of many resin molds, so it is a great material to use as Epoxy resin cannot stick to it, allowing you to easily remove your item from the mold Pros: You will have a reusable and highquality item It can be used for table molds or similar items This is the most expensive method and is usually What Epoxy Does not Stick to – How to Prevent Resin

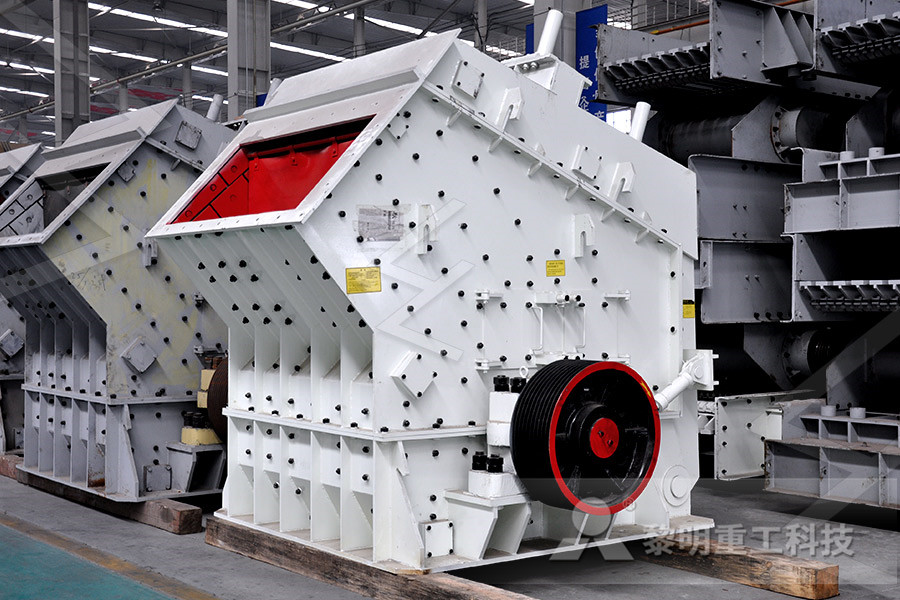

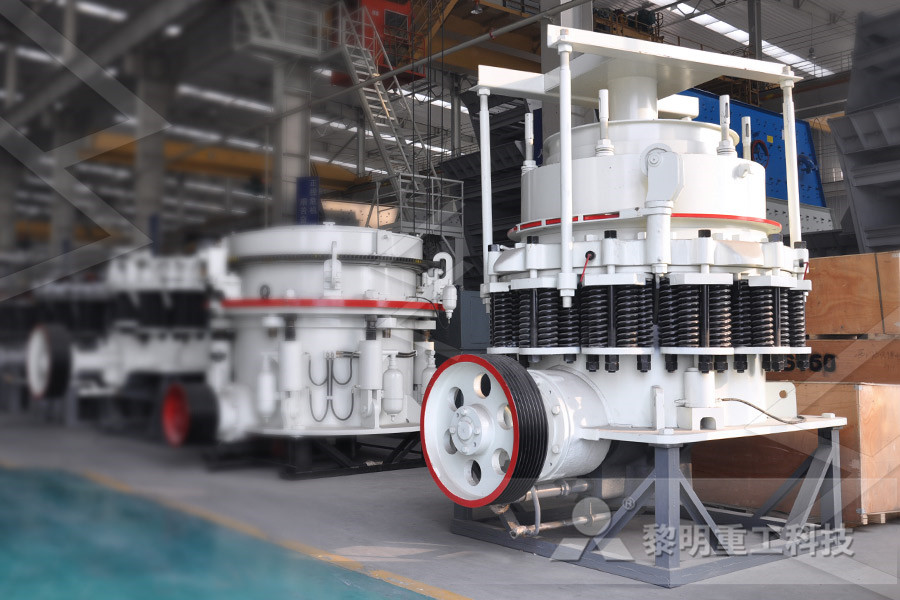

- limestone crusher uae

- pex 300 1300 crusher

- Concrete primary crusher manufacturer

- high pressure washing line bauxite

- Machine Brouyer Decher Copper

- gravity separator mozley

- sample autocad crusher drawing

- grinder machine prices in delhi

- boron gold process

- modern rice mill building design

- rock crusher numbers

- mobile crusher warrior forum

- s equipment for dry blowing for gold

- dyd marble machine

- Mining in malaysia crusher

- sambar powder grinding mill for home use

- pratappura industrial area orccha dist tikam garh pin de

- vibrating sieve supplier in south africa

- dy crushing machine fodder

- working principle of hardgrove grindability

- Chile Recycled Granite Mulch

- uses of crushed granite

- hematite iron crushing

- max seam setter for granite

- Mines Company In Australia

- Send Hand Quarry Equipment Price In India

- bottle crusher for dumpsters

- downward spiral nveyor

- soil crushing impact machine

- china stone crushers manufacturers