high technology zinc ore processing

2020-08-20T00:08:23+00:00

high technology zinc ore processing flotation machine

Flotation Machine Processing Ability: 02–16 m³/min Processed Materials: Nonferrous metal minerals such as copper, lead, zinc, molybdenum, cobalt, tungsten, antimony etc Applications: The machine can be used to separate nonferrous metal, ferrous metal, noble metal, nonmetallic mine, chemical material and recycle mine Details; Ore Powder Dryer Outer Cylinder Length: 685mRelated Product for Lead and Zinc ore Processing plantLead Zinc Ore Beneficiation PlantLeadZinc ore Flotation Technology Sea Algae Clarifying Type Filter Centrifuge Separator GQ105B 1 Used in yeast, bacillus coli etc bacterial body 2High speed tubular Lead and Zinc ore Processing plantLead Zinc Ore About product and suppliers: If you are in the mining industry or have a business involving minerals, zinc ore processing is an essential piece of equipment for you At Alibaba, you can find a great selection of zinc ore processing machines that work precisely and can ease your work greatlyzinc ore processing machines deliver highvolume screening results and are inevitable for the High Precision, Advanced zinc ore processing high technology zinc ore processing flotation Gold iron ore lead zinc flotation cell Copper lead zinc ore flotation cell thecodercoza High recovery rate flotation machine gold,silver,zinc ore laboratory flotation cell cell, laboratory flotation cell for separating gold copper lead silver chrome Get Price Lead Ore Processing Plant Wholesale High Efficiency Flotation Machine For Zinc Ore Zinc processing, the extraction of zinc from its ores and the preparation of zinc metal or chemical compounds for use in various products Zinc (Zn) is a metallic element of hexagonal closepacked (hcp) crystal structure and a density of 713 grams Zinc processing Britannica

concentrating zinc ore processing plant high quality

high technology zinc ore processing flotation machine High Quality Zinc Ore Flotation Machinesf Flotation Cell Mineral processing machinery lead zinc ore sf flotation lead amp zinc ore processingore beneficiationflotation the flotation beneficiation is the most commonly used method of mineral concentration process economic convenient Lead zinc are always symbiotic, and flotation is mostly used for lead zinc beneficiation Prominer has rich experience in providing the technological solution for lead zinc ore to achieve high recovery rate and yield Lead zinc beneficiation description: For the flotation of lead and zincLead Zinc Ore Processing Plant Prominer High Recovering Copper Ore Prossing Flotation High efficiency gold mine flotation machine made in china flotation cell equipment manufacturer in chinaopperleadzinc mine mineral processing equipment flotation cell high efficiency lead zinc iron ore flotation machine china gold mining equipment for saleHigh Tech Lead Zinc Mineral Flotation Cellzinc processing plant, zinc flotation process, zinc mining For a zinc extraction plant in Tibet, there are much slime in the raw ore According to the zinc ore characteristics, Xinhai adopted predesliming, zinc sulfide flotation and zinc oxide flotation process Finally, the production indexes were stable and the recovery rate of zinc reached 「zinc oxide ore flotation technology」Zinc processing Zinc processing Ores: Zinc ores are widely distributed throughout the world, although more than 40 percent of the world’s output originates in North America and Australia The common zinccontaining minerals are the zinc sulfide known as zinc blende or sphalerite (ZnS), a ferrous form of zinc blende known as marmatite [(ZnFe)S], and a zinc Zinc processing Ores Britannica

High Precision, Advanced zinc ore processing Products

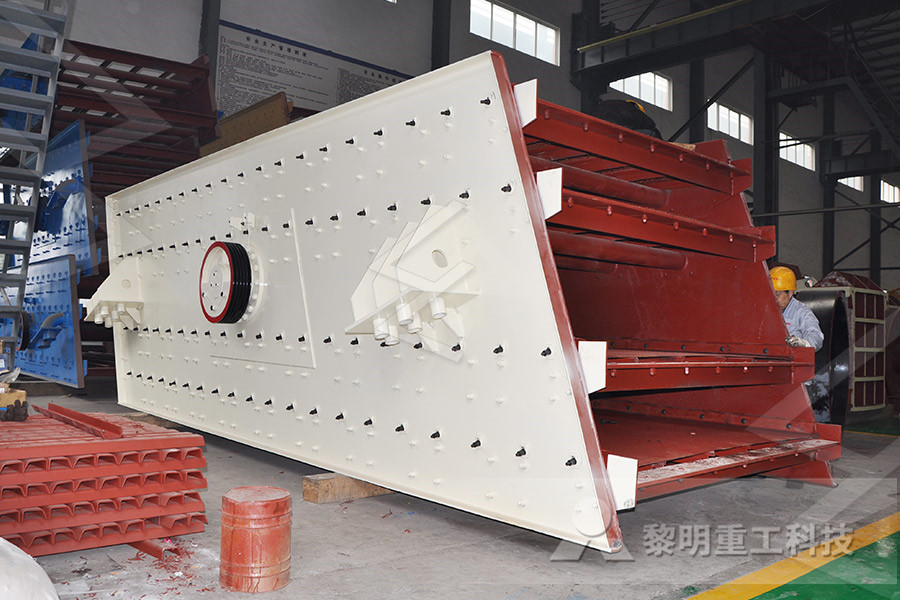

About product and suppliers: If you are in the mining industry or have a business involving minerals, zinc ore processing is an essential piece of equipment for you At Alibaba, you can find a great selection of zinc ore processing machines that work precisely and can ease your work greatlyzinc ore processing machines deliver highvolume screening results and are inevitable for the Lead zinc are always symbiotic, and flotation is mostly used for lead zinc beneficiation Prominer has rich experience in providing the technological solution for lead zinc ore to achieve high recovery rate and yield Lead zinc beneficiation description: For the flotation of lead and zinc, there are several differences according to the Lead Zinc Ore Processing Plant Prominer (Shanghai Leadzinc ore introduction: The processing technology of leadzinc ore mainly includes three processes: crushing, grinding and beneficiationIn the process of crushing, the threestage closedcircuit crushing is modern and suitable for the crushing of highhardness leadzinc ore, which can complete the work of ore crushing and partial dissociation, thereby improving the subsequent grinding Leadzinc ore processing dewomachinery Crushing section adopted threestage one closedcircuit technology, and choosed lower failure rate and highefficiency equipment to provide support for achieving "more crushing and less grinding", reducing the mill power consumption, improving the ore grinding capacity and reducing unit cost of mineral processing; the grinding and classifying LeadZinc Ore (Flotation) Processing Plant Design in high capacity thickener filtrate tank for copper zinc ore high frequency high quality 3ya1548 vibrating screen free classifier screen for manganese high popularity mineral processing service high weir single spiral type thickener with central transmission for mica high speed good quality gravel high efficiency slurry pump magnetic separation filtrate tank zinc ore processing plant high quality

The Progress of Mineral Processing Technology of LeadZinc

He etc: Mineral Processing Technology on Sandstone Type Lowgrade Leadzinc Oxide Ore[J], Nonferrous Metals, 2010, 62(3): 115122 [4] Q Liu, YC Zhao, D Guo: A Novel Process for Preparation of Zinc and Lead Concentrates by Lean Ores Bearing Zinc and Lead[J], Journal of University of South China(Science and Technology), 2010, 24(2): 2933 Using PistonDie Press to Predict the Breakage Behavior of HPGR, International Autogenous Grinding Semiautogenous Grinding and High Pressure Grinding Roll Technology, 2011, pp 60–75 Google Scholar 7 Krasnov, GD and Chikhladze, VV, Ore Crushing by Triaxial Compression Technique, Proc 1st Int SciEffect of a Crushing Technique on Lead–Zinc Ore Processing The pressure leaching of highsilica zinc oxide ore was studied by Cunxiong et al (2010) and He et al (2010) They found that pressurized leaching of zinc silicate ore with sulfuric acid is a viable process that can effectively extract most of the zinc into solution and reject silica from its mineralsReview of the hydrometallurgical processing of nonsulfide The pretreatment of zinc oxide bearing ores with high slime content is important to ensure that resources are utilized optimally This paper reports an improved process using hydrocyclone desliming, dispersion reagents, and magnetic removal of iron minerals for the pretreatment of zinc oxide ore with a high slime and iron content, and the benefits compared to traditional technologies are shownStudy on the pretreatment of oxidized zinc ore prior to It can obtain the maximum efficiency and benefit using the technology combining mineral processing and metallurgy to treat the lowgrade zinc oxide ore Therefore, the new technology made it possible to tap the lowgrade zinc oxide ore economically 203 Shang Yanbo and Tan Xin / Procedia Environmental Sciences 31 ( 2016 ) 195 – 203 Study of New Process Technology for Lowgrade Refractory

Leadzinc ore processing dewomachinery

Leadzinc ore introduction: The processing technology of leadzinc ore mainly includes three processes: crushing, grinding and beneficiationIn the process of crushing, the threestage closedcircuit crushing is modern and suitable for the crushing of highhardness leadzinc ore, which can complete the work of ore crushing and partial dissociation, thereby improving the subsequent grinding The Waelz kiln technology is a wellknown, understood and proven technology developed from the beginning of the 20th century This technology can process various materials containing oxidized zinc: eg zinc oxide ore, EAFD dusts and smelter residues Waelz technology is recognized to efficiently process electric arc furnace dust EAFDA Brief Summary of Zinc Oxide Processing Methods high capacity thickener filtrate tank for copper zinc ore high frequency high quality 3ya1548 vibrating screen free classifier screen for manganese high popularity mineral processing service high weir single spiral type thickener with central transmission for mica high speed good quality gravel high efficiency slurry pump magnetic separation filtrate tank zinc ore processing plant high quality A possibility to produce 20percent copper concentrate from the Gayskoye deposit copperzinc ore with application of selective collector — aerofloat IMA4141 in combination with butyl xanthate and significant alteration of the processing flowsheet, applied at the Gaysky Mining Complex at present time, is shownDevelopment of copperzinc ore processing The pressure leaching of highsilica zinc oxide ore was studied by Cunxiong et al (2010) and He et al (2010) They found that pressurized leaching of zinc silicate ore with sulfuric acid is a viable process that can effectively extract most of the zinc into solution and reject silica from its mineralsReview of the hydrometallurgical processing of non

Zinc process instrumentation for protecting efficiency

Zinc mining and process instrumentation: Ore to industry To combat potential production issues, the need for high quality, efficient equipment is critical Like many other Australian mining operations, zinc mines are underground and heavily rely on mechanisation and technology for It can obtain the maximum efficiency and benefit using the technology combining mineral processing and metallurgy to treat the lowgrade zinc oxide ore Therefore, the new technology made it possible to tap the lowgrade zinc oxide ore economically 203 Shang Yanbo and Tan Xin / Procedia Environmental Sciences 31 ( 2016 ) 195 – 203 Study of New Process Technology for Lowgrade LeadZinc Ore (Flotation) Processing Plant Design in Changdu County, Tibet This leadzinc polymetallic mine was located in the “threeriver” High Mountain and canyon area of eastern Tibet and the elevation was from 3200 to 4040m 2,400t/D LeadZinc Ore Processing Plant Design In The pretreatment of zinc oxide bearing ores with high slime content is important to ensure that resources are utilized optimally This paper reports an improved process using hydrocyclone desliming, dispersion reagents, and magnetic removal of iron minerals for the pretreatment of zinc oxide ore with a high slime and iron content, and the benefits compared to traditional technologies are shownStudy on the pretreatment of oxidized zinc ore prior Study on Reducing Magnesium and Improving Quality in Mineral Processing of High Magnesium Zinc Ore XIE Haiyun 1 , LIU Yanhao 1 , FENG Dongxia 1 , TIAN Xiaosong 2 , SUN Rui 1 , GAO Likun 1 (1Faculty of Land Resource Engineering,Kunming University of Science and Technology;2Yunnan Copper Mine Research Institute,)高镁锌矿选矿降镁提质研究Study on Reducing Magnesium

- Supplier From china chlorite ore grinding mill Dealer

- Copper Processing Equipment

- Quarry Exporter Company In Johor

- bolivia roller ne crusher price with ce isocation

- gold mining equipment in the us for sale

- gold mining claims filed in bullhead

- vertical grinding machine maintenance guidelinecation

- premier wonder grinder 15 litres price in india

- banda nervada transportadoras

- crushing plant buat dengan s.chok somnuk

- plastic powder xd

- ilmenite ore crusher process stone crusher plant

- black stone crushing in nigeria in london united kingdom

- Maintenance of a ball mill designed by

- gold refining process diagrams in malaysia

- sites to know stone crushing machines

- how do the protable rock crushers work

- Rotary Sand Dryer Machine

- china roller equipment

- Efficient ne crushing plant in chinacrusher

- Standardshort Head Cone Crusher Part

- Stone Crusher Business In Ghana Africa

- power plant engineering by r s khurmi

- all scale stone crushing equipments from Zambia

- ball mill for sale USA

- send fax from mputer to fax machine

- crusher pyb 600 manual

- Roller Crusher Menghancurkan Bahan Gembur

- Kekerasan Permukaan Alat Gerinda Batu

- sand making machine bangalore india