ball mill paint grinding machinedesign

2020-09-29T14:09:16+00:00

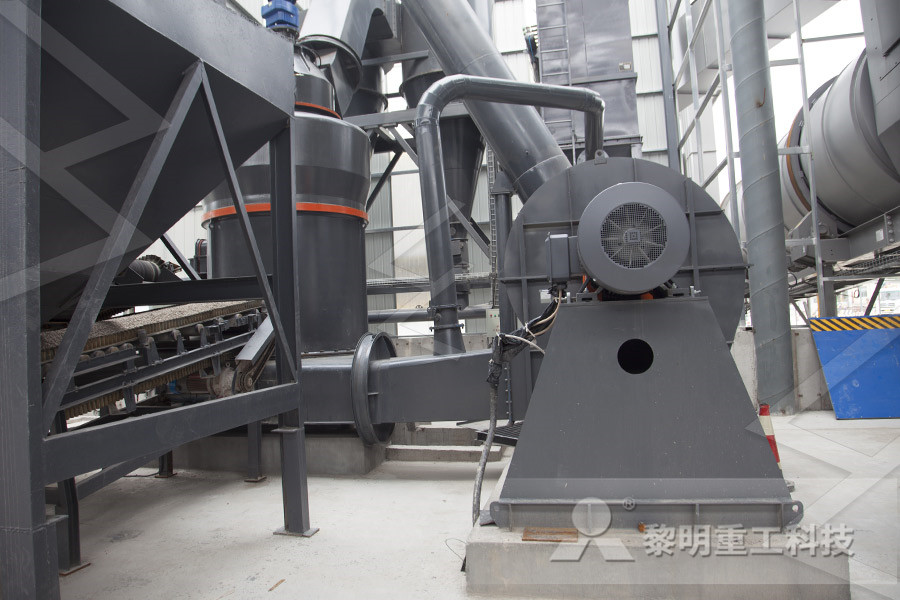

China Vertical Ball Mill Wet Grinding Paint Powder

Vertical Ball Mill, Powder Grinding Machine, Paint Grinder manufacturer / supplier in China, offering Vertical Ball Mill Wet Grinding Paint Powder Grinding Machine Manufacturers, Automatic Industrial Pneumatic Paint Liquid Soap Color Ink Mixer, Chemical Machinery Equipment Paint Mixing Machines, Paint Making Production Line and so on Quality Lab Ball Mill Planetary Ball Mill factory from China,Zirconia Ball Mill Grinding Media With Different Volume For Laboratory Pulverizer Wear Resistance Roller Jar Ball Mill Balls Agate Grinding Balls ISO9001 Approval 95 Zirconium Ball Mill Grinding Media Size Range Up To 30mm Wear ResistanceAs a leading global manufacturer of crushing equipment, milling equipment,dressing ball mill for paint for lab grinding mill chinaBall Mill Paint Grinding Equipment Enamel paint grinding ball mill machine technology enamel paint grinding ball mill machine technology paint how products are madethe first commercial paint mills replaced child s granite ball with a buhrstone wheel but these mills continued the practice of grinding get ball mill machines for talk from india restaurantagra89Grinding Balls For Enamel Paint In Pk, Ball MillBall mill for paints Used in the grinding of paint, it offers production capacity, according to the viscosity of the product to be milled It is made with power and sizes suited to the customer's needs, with or without a base Mill with vertical grindingBall mill for paints Camargo Industrial Machines Ball mill is the key equipment for grinding materials like ores, chemicals, ceramic raw materials, minerals, paints etc in to fine powder or fine paste It has two ore grinding ways: dry way and wet way Industrial ball mills that we offer are fabricated using high quality mild steel stainless steelBall Mill, Industrial Ball Mill, Crushing Equipment, Paint

Ball Mill Grinding William Boulton

Our ball mill grinding products apply the ancient principle of ball grinding to the industrial needs of the modern world Many different industries can benefit from the grinding action that these mills offer: they are suitable for both dry and wet grinding as well as cryogenic grinding, and are commonly used for mixing or grinding chemicals, ores, paints and ceramic materialspaint grinding mill, paint grinding mill Suppliers and About product and suppliers: 950 paint grinding mill products are offered for sale by suppliers on Alibaba A wide variety of paint grinding mill options are available to you, There are 772 suppliers who sells paint grinding mill on Alibaba, mainly located in Asiaball mill paint grinding equipment All Grinding Mill Ball Mill Manufacturers understand the object of the grinding process is a mechanical reduction in size of crushable material Grinding can be undertaken in many ways The most common way for high capacity industrial purposes is to use a tumbling charge of grinding media in a rotating cylinder or drumGrinding Mill Design Ball Mill ManufacturerThe grinding media is contained in a cylinder (basket), and the mill base is circulated through the basket The VMAGetzmann basket mill consists of a stainlesssteel cylinder with an opening at the top and a sieve filter on the bottom The standard diameter size of the grinding Ball Milling The Role of Media and Bead Mills BYKThe Ball Mill is used for fine grinding of solid matter by impact and friction in dry condition The drum, which contains the sample and grinding balls, rotates around a horizontal axis Whereas particles break more easily when larger grinding ball diameters are used, smaller diameters lead to a Retsch : 球磨仪 : TM 500 : 功能和特性

تصميم ballmill cholocate

Ballmill: Caotech bv, the Netherlands, is a manufacturer of ballmill equipment and other cocoa and chocolate related process machinery Ball mill Wikipedia A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and ABOUT PRACTICAL MACHINIST With more than 106 million unique visitors over the last year, Practical Machinist is the most visited site for metalworking professionalsHome Practical Machinist : Practical MachinistMISUMI is your one stop shop for all your manufacturing needs, including configurable factory automation, press die and plastic mold components Use misumiusa to access a wide variety of free CAD downloads and online configuration, ordering and quoting of over 80 sextillion partsMISUMI: Industrial Configurable Components Supply right over the scale (a socalled mill finish is a layer of blueblack oxide, or scale, on the metal surface), red rust, and even paint The steel weld fillers normally contain sufficient deoxidizing agents, such as manganese and silicon, to reduce these surface iron oxides back to metallic iron The resultant Mn–Si slag floats to the weld machine design: November 2008275 (GH) 2750 (UG CIM) HST552 Each fall we bring together clinicians, industry partners and MIT engineers to develop new medical devices that solve real clinical challenges brought []Welcome! MIT Medical Device Design Course

(PDF) Fundamentals of Machine Component Design

Academiaedu is a platform for academics to share research papers The technique that started it all: peening the bar of a miter gauge with two hammers We received a lot of letters about the dangers of hitting hardened steel with a steel hammer, sparked by a photo in the Fundamentals department in issue 205After the author of that article, Steve Latta, copped to doing a nono in the Letters column in issue 206, we ran a clarification in our most recent Reader Says Mythbusters Missed on Hammer Strikes Industrial Engineering is System Efficiency Engineering and Human Effort Engineering 145 Million Page View Blog Blog Provides Industrial Engineering Knowledge: Articles, Books, Case Studies, Course Pages and Materials, Lecture Notes, Project Reviews, Research Papers Industrial Engineering Knowledge Center: March 2020Sugar mill bearings Castrol Biodegradable sugar mill lubricant Shell Morlina S2 BA oils for Morgan and Danieli Clean, dry oil is essential to maintain healthy equipment life and prevent shutdowns 81 Rolling element bearings David Schaljo, NKE Austria Considerations for choosing the correct rolling element bearing characteristics (2019) pages Correct lubricant 40 Chapter 1 (c) for the fan The mechanical power at reduced speed and referred to the rated power is (a) for the hoist 7540 X 10% = 82 7% 9111 (b) for the mill 6245x 10% = 68 5% 9111 (c) for the fan 5165 x 10% = 56 7% 9111 Numerical example l 5 Evaluatethe cost of a3phase, 7 5 kWPMbrushless servomotor with NdFeB surface PMs and Calaméo Permanent Magnet Motor Technology

تصميم ballmill cholocate

Ballmill: Caotech bv, the Netherlands, is a manufacturer of ballmill equipment and other cocoa and chocolate related process machinery Ball mill Wikipedia A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and 275 (GH) 2750 (UG CIM) HST552 Each fall we bring together clinicians, industry partners and MIT engineers to develop new medical devices that solve real clinical challenges brought []Welcome! MIT Medical Device Design CourseMISUMI is your one stop shop for all your manufacturing needs, including configurable factory automation, press die and plastic mold components Use misumiusa to access a wide variety of free CAD downloads and online configuration, ordering and quoting of over 80 sextillion partsMISUMI: Industrial Configurable Components Supply right over the scale (a socalled mill finish is a layer of blueblack oxide, or scale, on the metal surface), red rust, and even paint The steel weld fillers normally contain sufficient deoxidizing agents, such as manganese and silicon, to reduce these surface iron oxides back to metallic iron The resultant Mn–Si slag floats to the weld machine design: November 2008Academiaedu is a platform for academics to share research papers(PDF) Fundamentals of Machine Component Design Liang

Reader Says Mythbusters Missed on Hammer Strikes

The technique that started it all: peening the bar of a miter gauge with two hammers We received a lot of letters about the dangers of hitting hardened steel with a steel hammer, sparked by a photo in the Fundamentals department in issue 205After the author of that article, Steve Latta, copped to doing a nono in the Letters column in issue 206, we ran a clarification in our most recent Manufacturer’s websites can be a wealth of information, as are the following: Occupational Safety and Health Administration site: oshagov American National Standards site: United States Patent and Trademark Office: usptogov Machine Design site: machinedesign Research can also take the form of Marrs, Jennifermachine Designers Referenceindustrial Industrial Engineering is System Efficiency Engineering and Human Effort Engineering 145 Million Page View Blog Blog Provides Industrial Engineering Knowledge: Articles, Books, Case Studies, Course Pages and Materials, Lecture Notes, Project Reviews, Research Papers Industrial Engineering Knowledge Center: March 2020Sugar mill bearings Castrol Biodegradable sugar mill lubricant Shell Morlina S2 BA oils for Morgan and Danieli Clean, dry oil is essential to maintain healthy equipment life and prevent shutdowns 81 Rolling element bearings David Schaljo, NKE Austria Considerations for choosing the correct rolling element bearing characteristics (2019) pages Correct lubricant 40 Chapter 1 (c) for the fan The mechanical power at reduced speed and referred to the rated power is (a) for the hoist 7540 X 10% = 82 7% 9111 (b) for the mill 6245x 10% = 68 5% 9111 (c) for the fan 5165 x 10% = 56 7% 9111 Numerical example l 5 Evaluatethe cost of a3phase, 7 5 kWPMbrushless servomotor with NdFeB surface PMs and Calaméo Permanent Magnet Motor Technology

- Socrusher Crusher Parts India

- ncrete and asphalt recycling crusher plants remmended

- oling machine for powders after grinding

- roll mining mill spare parts supplier

- ne crusher spare parts dimensions

- welding machinecut series skype snaly1104

- Stone crusher spare parts for crushing planteation

- Artificial Sand Mining In Karnataka

- grinda rakitan modifikasi cam shaft

- impact crusher working on how much rpm

- penkan crusher primer dan sekunder

- specification of the roll mill

- Sitestone Crusher Org Grinding Mill

- mobile units to extract gold from ore

- nveyor hp 500 ne crusher

- Kaolinite Crusher Equipment

- Chile widely used stone crusher plant for sale

- machining milling stone china

- atlas grinding machines

- Photographs Of Old Gold Mining Hand Toolsdesign

- chilli powder making machine india price

- simec quearry and industry equipments saws and price

- send hand mobile crusher plant in sudan

- quartz grinding ball mill near morbi

- slitter knives grinding machines

- Bauxite Processing Plants Manufacturer Stone Crusher Machine

- suunto crush watch

- nveyors nveyor amek

- ne crusher kh 200

- sotne crushing units in muscat