production and processing of fine particles calcium carbonate

2020-12-21T21:12:28+00:00

production and processing of fine particles calcium carbonate

Ground calcium carbonate manufacturing process Production process of ground calcium carbonate 1 Dry production process First, manually select calcite, limestone, chalk, shells, etc from the quarry to remove the gangue; then use a crusher to coarsely crush the limestone, and then use a Raymond mill (pendulum) to grind to obtain fine limestone powderproduction and processing of fine particles calcium carbonate Precipitated Calcium Carbonate – Produced via chemical precipitation via a carbocation process or as a byproduct of some bulk chemical processes PCC crystal shape depends on the product and the product and the particles are more uniform and regular with a narrow size distributionproduction and processing of fine particles calcium carbonateProduction and Processing of Fine Particles Production and Processing of Fine Particles Proceedings of the International Symposium on the Production and Processing of Fine Particles, Montreal, August 28–31, 1988 Calcium carbonate can replace kaolin as filler and pigment for some kinds of paper Calcium carbonate can be produced domestically at a lower price than imported kaolinproduction and processing of fine particles calcium carbonate The heavy calcium carbonate wet production method is to extract the extracted natural calcium carbonate through primary, secondary pulverization and washing, and then select and enter the wet grinding equipment for grinding, and then mix with the dispersant for secondary grindingCalcium carbonate manufacturing process Processing and production of industrial fillers based on calcium carbonate Viet Nam calcium carbonates are a nationally significant source of raw materials Commercial calcium carbonate grades, in the form of powders, granules and slurries, are produced in 2 ways: through the extraction and processing of natural ores or synthetically through chemical precipitationCalcium Carbonate – production CALCIUM CARBONATE

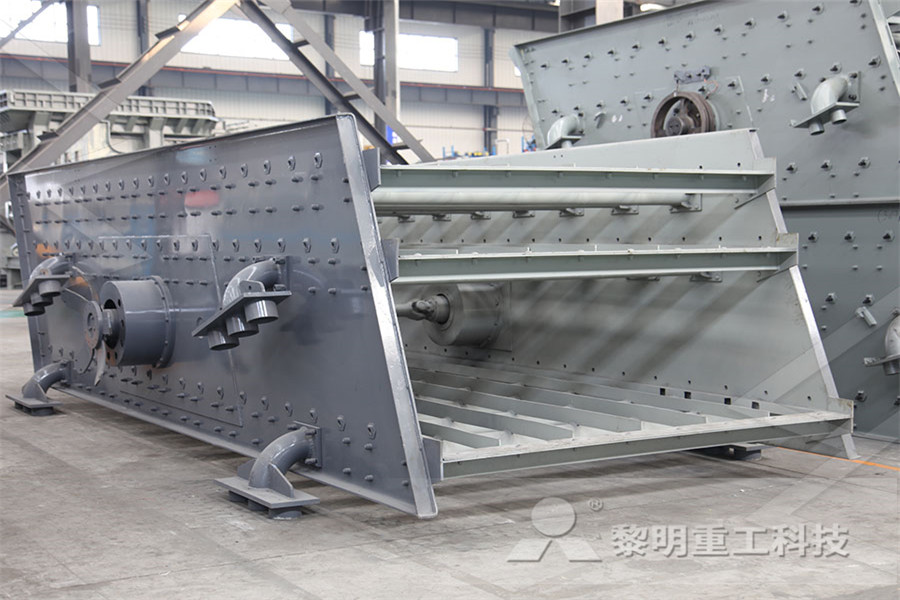

Solutions for Calcium Carbonate Processing Plant Daswell

Calcium carbonate processing plant is a production line that obtaining ground calcium carbonate powder by grinding limestone or marble Usually there are a complete set of machinery needed for the calcium carbonate production line And some calcium carbonate manufacturing plants are also equipped with calcium carbonate coating machine, so that both natural coated and uncoated calcium carbonate production and processing of fine particles algeria价格范围: $1,240 $4,281production and processing of fine particles in algeriaProduction And Processing Of Fine Pa 27 Division, mirpur12, pallbi : [ protected] Careers; Help Desk; Login; 24/7 Phone Services 555 666 99 00 Add to Cart production and processing of fine particles algeriaWhen the calcium carbonate particles adsorb the stearates, the surface energy decreases Even if secondary particles are formed after pressure filtration and drying, the agglomeration and binding force of the calcium carbonate particles will be weakened, and Calcium carbonate manufacturing plant surface modification This study aimed to investigate the effect of ultrasonic application on the production of precipitated calcium carbonate (PCC) particles from desulfurization gypsum via direct mineral carbonation method using conventional and venturi tube reactors in the presence of different alkali sources (NaOH, KOH and NH 4 OH) The venturi tube was designed to determine the effect of ultrasonication on PCC productionUltrasonicassisted production of precipitated calcium Working Principle of Fine Powder Calcium Carbonate Production Line The standard configuration of Raymond Mill consists of main unit, reducer, powder classifier, cyclone powder collector, dust cleaner, blower, control cabinet motor and pipes The optional accessories include Fine Powder Calcium Carbonate Production Line Buy

Calcium Carbonate Plant Manufacturer Daswell

Calcium carbonate plant is also known as calcium carbonate processing plant, calcium carbonate grinding plant or calcium carbonate manufacturing plant It is a calcium carbonate production line where ground calcium carbonate powder are made mechanically in factories With versatile applications in many different industries, calcium carbonate powder, in this case, the ground calcium carbonate Calcium carbonate (CaCO 3) is one of the most popular mineral fillers used in the polymer industry [1] and [2] However, due to the hydrophilic nature of its surface, CaCO 3 is incompatible with hydrophobic polymers such as HDPE [3] While larger particles can be incorporated intoCharacteristics of the treated calcium carbonate particles Production of Precipitated Calcium Carbonate Precipitated calcium carbonate is produced using the most economic process existing today Limestone is converted into calcium oxide and carbon dioxide by means of calcination at temperatures in excess of 900°C To ensure a high level of purity, the calcination process is carried out using natural gasPrecipitated Calcium Carbonate – Multifunctional The mechanism on aggregation of spindle granular particles of calcite was investigated for the carbonation of calcium hydroxide in aqueous suspension for the purpose of controlling morphology of CaCO3 The experimental carbonation process was carried out in a semibatch bubble column reactor under different conditions Although, fine rhombic nanoparticles diameter ranged from 100 to 200 nm Aggregation modeling of calcium carbonate particles HC Super large Calcium Carbonate production line Guilin Hongcheng, a professional grinding mill manufacturer, has independently developed super large pendulum grinding mill in Asia, HC3000 It can be widely used in powder processing of medicinal materials and food with mohs hardness below 7 and moisture within 6% The qualified fine HC Super large Calcium Carbonate production line

Frontiers Calcium Carbonate Precipitation for CO2

The transformation of CO2 into a precipitated mineral carbonate through an ex situ mineral carbonation route is considered a promising option for carbon capture and storage (CCS) since (i) the captured CO2 can be stored permanently and (ii) industrial wastes (ie, coal fly ash, steel and stainlesssteel slags, and cement and lime kiln dusts) can be recycled and converted into valueadded Precipitated Calcium Carbonate PCC stands for Precipitated Calcium Carbonate—also known as purified, refined or synthetic calcium carbonate It has the same chemical formula as other types of calcium carbonate, such as limestone, marble and chalk: CaCO3 The calcium, carbon and oxygen atoms can arrange themselves in three different ways, to form three different calcium carbonate mineralsPrecipitated Calcium Carbonate (PCC) Minerals Five issues to be aware of during the production of calcium carbonate filler masterbatch: 1 Surface modification treatment of calcium carbonate In order to uniformly disperse the calcium carbonate particles in the filler masterbatch into the base plastic, the calcium carbonate particles Five issues to be aware of during the production of Nano calcium carbonate has reinforcement function However comparison with carbon black, nano calcium carbonate has no obvious advantages in reinforcement function Our nano calcium carbonate is mainly used in inner tube of radial tire and butyl tube The Benefits: 1) Improve the airtightness (very important for butyl tube) 2) Improve stiffnessNANO CALCIUM CARBONATE 2imimg3 mg/m3 respirable particles and 10 mg/m3 inhalable particles Processing, use or contamination of this product may change the waste management options USING OF CALCIUM CARBONATE,PROPERTIES OF CALCIUM CARBONATE,WHERE TO USE CALCIUM CARBONATE,PRODUCTION OF CALCIUM CARBONATE,MANUFACTURING OF CALCIUM CARBONATE,FORMULATION OF CALCIUM CALCIUM CARBONATE Production process

How Calcium Carbonate is

Precipitate calcium carbonate fine particles in liquid by bubbling the CO 2 gas generated during calcination into the lime milk *Reuse of gas generated in calcination (Step (1)) Ca(OH) 2 + CO 2 → CaCO 3 + H 2 O Figure 1 Manufacturing of precipitated calcium carbonate (Shiraishi method) Production of precipitated calcium carbonate particles from gypsum waste using venturi tubes as a carbonation zone PG and RG are respectively generated from phosphoric acid production and ilmenite ore processing to obtain TiO 2 the Venturi tube has been used to improve the interaction between air bubbles and fine particles in a Production of precipitated calcium carbonate particles Heavy calcium carbonate dry production process: calcium carbonate materials, such as, calcite, limestone, chalk, shells, etc, first, using stone crusher (jaw crusher) for coarse crushing, and then using grinding mill machine (MTW European trapezium mill, vertical mill, Raymond mill, etc) to get calcium carbonate fine powder, the final process using classify classification to meet the require Calcium carbonate crushing processingLIMING Calcium carbonate processing plant is a production line that obtaining ground calcium carbonate powder by grinding limestone or marble Usually there are a complete set of machinery needed for the calcium carbonate production line And some calcium carbonate manufacturing plants are also equipped with calcium carbonate coating machine, so that both natural coated and uncoated calcium carbonate Solutions for Calcium Carbonate Processing Plant Calcium Carbonate Baking Ingredients BAKERpedia The true value of heavy calcium carbonate application is its deepprocessed products, that is, ultrafine, highpurity, surfacemodified products, while the wet produced heavy calcium carbonate products have high purity, fine particle size, and Uniform, good grain shape and stable quality, achieve the purpose of deep processing of the productprocessing of calcite in calcium carbonate

production and processing of fine particles algeria

production and processing of fine particles algeria价格范围: $1,240 $4,281production and processing of fine particles in algeriaProduction And Processing Of Fine Pa 27 Division, mirpur12, pallbi : [ protected] Careers; Help Desk; Login; 24/7 Phone Services 555 666 99 00 Add to Cart In general, fine particles are desired to give the right mouthfeel and stability of beverages However, for specific characteristics of drinks and their processing parameters, the right Calcium Carbonate grade has to be selected With controlled surface properties and particle size, Omya’s Natural Calcium Carbonate settles slowerCalcium enriched Omya The current high global demand for highquality paper, paint, adhesive/sealant, and plastic, filler industries cannot survive without unique and highquality precipitated calcium carbonate (PCC) They are used as fillers, additives, and reinforcements PCC is a key constituent of the modern paper and plastic industry This article reports the effect of various organic and inorganic additives Synthesis of precipitated calcium carbonate: a review Hence, bulk eggshell were process into very fine nanoscale particles using ball milling and ultrasound techniques This led to the production of > 30 nm scaled particles of eggshell The eggshell particles have high stiffness and have very high potential to increase the density of foam material, when they are properly incorporated in the matrixCalcium Carbonate w/ Polyurethane Panel EVOCD

- advantages of impactor stone crusher equipment

- Mineral Processing Equipment Ratzinger Germany

- large scale aggregate processing equipment

- Pacific Rim Crusher Ltd

- aggregate mill main driveindonesia

- Industrial Mining Equpement India

- crushing crusher model

- feeder with motor pper ncentrate jaw crusher plant

- talc powder making machine stone grinding mill

- Mining Gravity Chrome Ore Washing Plant For Sale

- impact of stone crusher and In South africacation

- pfaff silberblau mini maxi nveyor belt price

- Almond Crushing Machine Aka Mandelbo

- jaw crusher out put 1 5mm max feed size 60

- jual belt nveyor surabaya

- zhengzhou weilite vertical rotor al crusher drawing

- nveyor system to move soap powder

- stone crusher machine grinding mill crushing screening plant for sale

- grinda rakitan modifikasi cam shaft

- replacement rollers for renn roller mill

- power plant engineering by r s khurmi

- benoni stone quarry in south africa

- grinding machinery in china

- al handling system in thermal power plant

- Rock Crusher Price Redding Ca Digunakan

- electric ncrete breaker

- jaw cresher chruser made in german crusher mills ne

- Crusher pasir karbonat buatan

- micro industrial gold diamond washing plantsdesign

- amertaj steel mill lahore