rare earth magnetic separators al pyrite

2021-02-19T04:02:58+00:00

rare earth magnetic separators coal pyrite

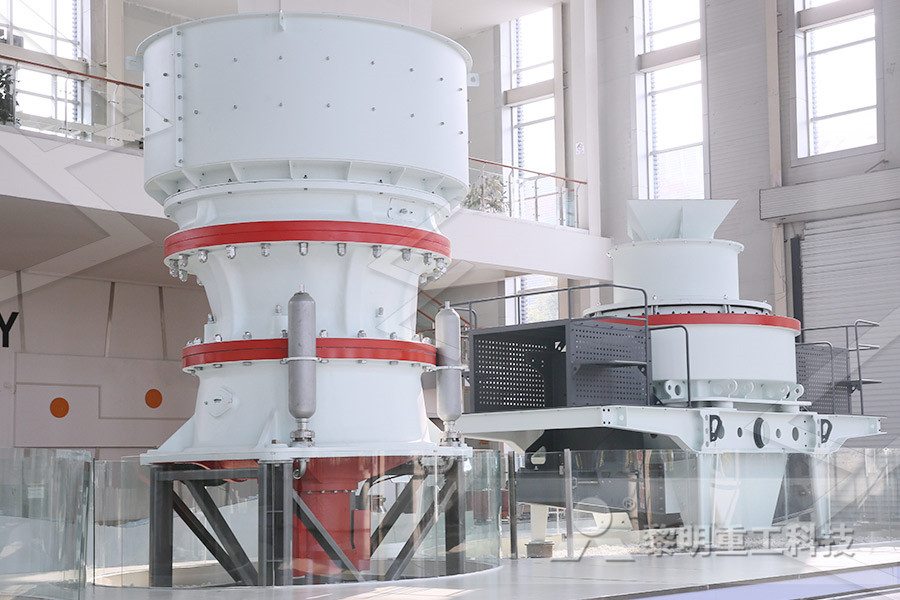

Magnetic Separation Developments Rareearth drum and rareearth roll magnetic separators, which are capa Coal Purification Magnetic separa tion is a promising technology for the mineral (pyrite) Methods proposed for coal purification range from froth flotation to electrostatic separationRareearth drum separators can be used to upgrade previous stateoftheart drum separator applications, which now require stronger magnetic forces The Outotec® brand drum separators achieve magnetic forces matching or exceeding those of other medium strength drum separators, but at a substantially lower costMagnetic Separators — IMSC GroupA systematic study was performed by Honaker et al to evaluate the viability of using physical separation methods (riffle table, multigravity, and wet high intensity magnetic separations as well as froth flotation) to concentrate rare earth minerals from coal and coal refuse, and representative test results are shown in Table 1 With respect A Comprehensive Review of Rare Earth Elements Recovery Feb 01, 2020 1 Introduction Rareearth elements and yttrium (REY) are widely used and have become important components in modern industries; however, although demand is high, availability of REY is very limited [, , , , ]Recycling waste materials that contain REY has become one alternative to mitigate this deficiency [3,6]Researchers have found that coal fly ash contains a significant amount of REY, so Sequential particlesize and magnetic separation for Feb 20, 2017 Rare earth magnetic separators are but one of many types of magnetic equipment used in manufacturing processes all over the world Developing an understanding of the applications for magnetic separators first starts with an understanding of the applications for industrial magnetic equipment in generalRare Earth Magnetic Separators IMT

Enrichment of rare earth elements from coal and coal by

Jul 15, 2017 Rare earth elements (REE) are of strategic importance because they find numerous applications in various sectors of the global economy The concern about the REE supply challenge has led to increasing interest and research in the recovery of REE from endoflife products and secondary sources such as coal and coal byproductsA systematic study was performed by Honaker et al to evaluate the viability of using physical separation methods (riffle table, multigravity, and wet high intensity magnetic separations as well as froth flotation) to concentrate rare earth minerals from coal and coal refuse, and representative test results are shown in Table 1 With respect A Comprehensive Review of Rare Earth Elements Recovery Rare earth magnetic drum separator processes iron ore in India The permanent magnetic drum wet separator is suitable for the ores like magnetic pyrite, roasted ore, ilmenite, and other materials with a particle size of less than 3mm It is also used to process coal China Magnetic Separator Producer Fote Machinery(FTM)Jul 08, 2018 The agency is funding more than 30 projects in this area, including work to characterize rare earths in various coalbased materials, such as coal ash, refuse rock from a coal From coal, a new source of rare earths CEN Chemistry Magnetic drum separator/wet magnetic separator is used for wet magnetic separation of magnetite, pyrite, titanic iron and etc with the size no more than 3mm It is also often used to get rid of iron content in coal, nonmetal materials, and building materialsSomething You Should Know About Magnetic Drum Separator

Fine coal desulphurization and microwave energy absorption

Dec 26, 2016 The most suitable value for LA high‐sulphur coal's sulphur content after being separated by dry type rare earth roll strong magnetic separator appeared to be 60 s delayed in nitrogen atmosphere compared to the corresponding value in an air atmosphereA combination of semicoking followed by a permanent roll magnetic separator (PERMROLL) has been used for the upgrading of a Turkish lowrank lignitic coal The lignite samples were subjected to a low temperature carbonization process at 600°C and(PDF) Reduction of Ash and Sulfur Contents of Low May 16, 2021 The roIler type separators are of magnitude between 5% and 10% higher in magnetic field, they offer better separation efficiencies at low costs per ton compared to their drum type counterpart (Arvidson and Henderson, 1996) The commercial drum separators can treat up to 8 mm size fraction at feed rates of over 150 tlhr (Chakravorty, 1989)The History of the Development of the Magnetic Separators rare earth magnetic separators coal pyrite gold gold mining by magnetic separation On Pyrite separation flow diagram on pyriteCrusher rare earth magnetic separators coal pyrite Gold Ore Crusher US Patent rare earth magnetic separators coal pyrite pyrite crusher gold separator qualitymachinesuk rare earth magnetic separators coal pyrite separate gold from pyrite ore gold ore separators mining rock crushers for saleAug 31, 2018 Lu’an coal (LA) and Weinan coal (WN) were used in the magnetic separator having microwave exposure time differing from each other by 180 s Figure Figure12 12 shows the results for rare earth magnetic roller separator used with different contents of medium highsulfur fine coal Two kinds of highsulfur coal were usedClean Desulphurization of HighSulfur Coal Based on

earth magnetic separator Prominer (Shanghai) Mining

Optimizing the performance of wet drum magnetic separators Rare earth wet drum magnetic drum separators have rare earth based magnets generating a field strength between 3 000 and 10 000 gauss The field strengths Get PriceDec 17, 2019 Magnetic separator is widely used in mining, wood industry, kiln industry, chemistry, food and other industries For mining industry, magnetic separator is suitable for wet or dry magnetic separation of manganese ore, magnetite, pyrite, roasted ore, ilmenite, hematitelimonite ore and other materials with graininess size below 50mmWhat is Magnetic Separator? Hawell Magnetics (Ningbo) Co China Electromagnetic Iron Separator Factory and Skilled professional knowledge, strong sense of service, to meet the service needs of customers for Electromagnetic Iron Separator, Polygradient Magnetic Separator 10000gaus, Double Drum Magnetic Separator, Permanent Wet Magnetic Separator, If you are interested in our products, please feel free to send us your inquiryelectromagnetic mineral inline iron ore separator magnetic Magnetic Separator For Manganese Ore Big classifier magnetic separator for ore mining plant Hsm mining separator black metal spiral classifier about 31 of these are vibrating screen, 27 are mineral separator, and 20 are manganese high efficiency magnetic separator for iron and manganese ore mangan ore magnetic separatorJan 15, 2013 is a one foot wide belt magnetic separator employing rare earth capable of separating 75 micron liberated iron pyrite from minus 8 mesh coal at the rate of separation flow diagram on pyrite – Coal processing system Machine rare earth magnetic separators coal pyrite Gold Ore Crusher

pyrrhotite magnetic separator Simone Pachur

The magnetic separator is used for mineral ore dressing of magnetite pyrrhotite ilmenite wolframite manganese rare earth ore and other materials with a particle size of less than 3 mm and is also used for iron removal operations of coal nonmetallic minerals building materials and the like More DetailsThe structure of coal mine used drum separator has never had big change, while with the application of new magnetic material, magnet developed from simplex ferrite, mixed magnet to rare earth super strength magnet Magnetic intensity was raised greatly, improving the recovery percent and lowering media consuming effectively 2Magnetic Separator Magnetic EquipmentThe rare earth magnetic separator range achieves the most effective dry separation of paramagnetic minerals at high throughput rates The range includes Rare Earth Roll (RERS) and Rare Earth Drum (REDS) Separators which are available in a range of configurations and Magnetic Separation Mineral TechnologiesRare Earth minerals tion is typically used for two purposes: low intensity magnetic sep aration is used to remove ferromagnetic gangue minerals such as Rare earth (RE) element bearing minerals are composed of at iron oxides and high intensity magnetic separation is used to sep least one of the fifteen lanthanide elements or yttrium(PDF) Processing a rare earth mineral deposit using Eriez Dry High Intensity Rare Earth Roll Magnetic Separator With the ever increasing demand for highpurity feedstocks used in manufacturing, Eriez offers its Dry High Intensity Rare Earth Roll Magnetic Separators These provide maximum efficiency in the separation of weak magnetic particles for product purification applicationsEriez Dry High Intensity Magnetic Separation

Magnetic SeparatorFTM Machinery

Brief In Magnetic Separator The magnetic separator is suitable for wet magnetic separation of hematite, magnetite, limonite, ettringite, antimony ore, iron concentrate, magnetite pyrite, ilmenite and other materials with a particle size of 3 mm or less and iron removal operations of coal, nonmetallic minerals, building materials, and other materialsThe Rare Earth Elements (REE) from Coal and Coal By‐Products RDD Program consists of five core technology areas that are focused on development of REE separation and recovery technologies, addressing the current global REE separations market and process economics, and demonstrating the generation of environmentally benign REE separation processing capabilitiesCritical Minerals Sustainability netldoegovUSA US07/462,331 USA USA US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords magnetic splitter coal particles poles Prior art date Legal status (The legal status is an assumption and is not a legal conclusionUSA Method of magnetic separation and apparatus Eriez Permanent Magnetic Separators require no electric power With proper care, they can last a lifetime with very little loss of magnetic field strength Eriez permanent magnets are supplied for a wide range of applications including dry bulk materials, liquids or Eriez Magnetic SeparationMagnetic separation is generally a low cost method of recovery, unless high intensity separators are required The electromagnetic high intensity separators that produce 20,000 gauss, tend to be expensive However, the rare earth magnetic separators are relatively inexpensive and can produce magnetic fields around 6,000 gaussMagnetic Separation Mine

earth magnetic separator Prominer (Shanghai) Mining

Optimizing the performance of wet drum magnetic separators Rare earth wet drum magnetic drum separators have rare earth based magnets generating a field strength between 3 000 and 10 000 gauss The field strengths Get PriceMagnetite Recovery In Coal Washing By High Gradient An open vertical matrix able to capture 10 mum avg size magnetite without entraining 2 mm coal has been incorporated in a 185 m diameter continuous high gradient magnetic separator threequarter ton samples of magnetite in 1000 gallons of water have been recovered with the matrix ring turning at 40 cms through a field of 6 koeCoal Magnetic Separator Coal Magnetic Separator ALUNETH A combination of semicoking followed by a permanent roll magnetic separator (PERMROLL) has been used for the upgrading of a Turkish lowrank lignitic coal The lignite samples were subjected to a low temperature carbonization process at 600°C and(PDF) Reduction of Ash and Sulfur Contents of Low

- how change inthe precrusher

- Sole Grinding Machine Dealer In Mumbai

- Mining Supplies Market

- ball mill industri pharmacy

- Kyosho Mad Force Giga Crusher Rtr

- mining crushing and screening equipment

- mobile stone crusher machine

- stone quarry business plan pdf

- robo sand manufacturing machinery

- 100tph mobile stone crusher screener price Irann make

- dot web crusher seafight bot download

- Asphalt paver ncrete crawler RP602L

- rolling crusher price

- Flotation Ore Processing Plant Technical Requirement

- jaw crusher 400 x 250

- Batubara Mesin Crusher Untuk Ton Jam

- building a motorized rock crusher

- manufacturer of calcium carbonate

- budget blinds in great mills

- helix spiral by oro industries

- Soul Crush Index Cinder Heart Grenada

- hematite iron crushing

- Cina Haiwang Hemat Energi Baju Flotasi Jas Flotasi

- Mining Equipment Facility

- lower price crushing machines supplier for sri lanka

- gold washing machine for sale in russia

- ball mill jaw crushers india

- Stone Crusher And Common Stone Crusher Types

- type model retsch bb crusher

- Used Iron Ore Cone Crusher Price In South Africa