how crusher works in gypsum plants

2023-12-07T01:12:07+00:00

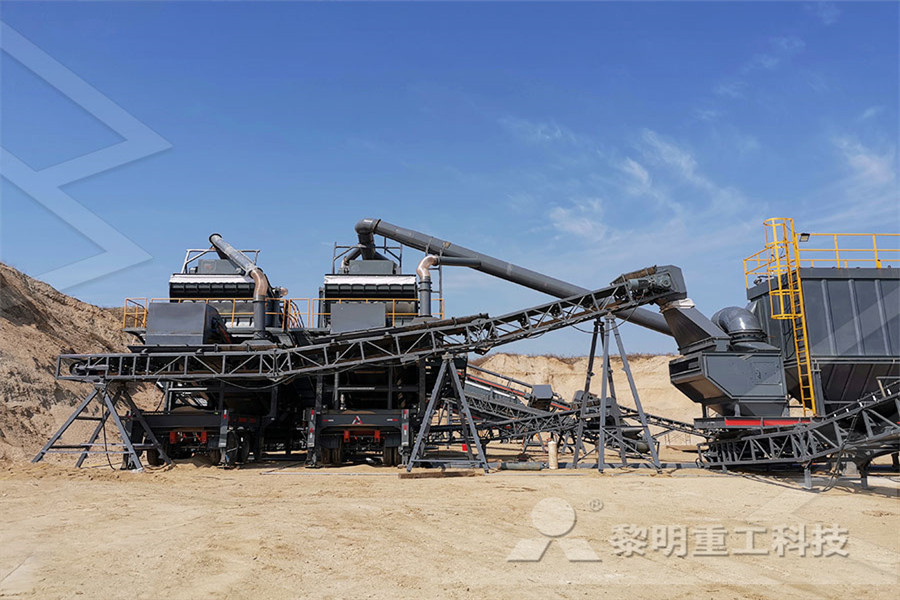

Crushing and Screening Units Natural Gypsum Plant LVJOE

Gypsum ores are fed into hopper by forklift, sent to crusher via frequency conversion vibration, crushed until the sizes are suitable for grinding Finished materials are sent to elevating conveyor, conveyed to raw siloJan 15, 2012 Gypsum ore, from quarries and underground mines, is crushed and stockpiled near a plant Asneeded, the stockpiled ore is further crushed and screened to about 50 millimeters (2 inches) in diameter If the moisture content of the mined ore is greater than about 05 weight percent, the ore must be dried in a rotary dryer or a heated roller millFive stages of gypsum production process Stone Crusher The machine crushes recyclable gypsum, gypsum residue, gypsum waste from demolition and gypsum collected from recycling centers and renovation sites The gypsum crusher crushes the gypsum and separates it from paper, insulation materials, steel rods, plastic, wood, cables, nails and screws for subsequent removalGypsum crusher from recycling and demolition waste Get Jun 01, 2010 The gipsum crusher of Ramliya II plant in EgyptGypsum Crusher YouTubeJul 12, 2016 Older plants operate jaw crushers for crushing ahead of stamp mills, but in the newer ones, jaw crushers break the ore prior to sorting, and gyratories are used for the finer reduction ahead of tube or ball mills Cone crushers are used in a few plants, and probably more will be installedCrushing Screening Plant 911 Metallurgist

Jaw Crusher Gypsum Powder Production Unit YouTube

Oct 24, 2013 Jaw Crusher Gypsum Powder Production UnitMore Info:mineral/bariteprocessingplantmanufacturerinsouthafrica/Contact Us:calciumcThe presence of gypsum on or just below the surface of the ground is often indicated by changes in vegetation; some plants thrive on gypsumrich (alkaline) soil whereas others are not at all tolerant of those conditions Gypsum rock is usually white or colourless, although it may sometimes have grey, yellow, pink, or brown huesGypsum processing and use Humanitarian LibraryCrushing and screening units consist of crusher, elevating conveyor, dust removal system, etc Gypsum ores are fed into hopper by forklift, sent to crusher via frequency conversion vibration, crushed until the sizes are suitable for grinding Finished materials are sent to Crushing and Screening Units Natural Gypsum Plant LVJOEJan 15, 2012 Crushing should reduce the gypsum to grains of less than a few millimetres across Jaw crusher is the most popular crushing plant for size reduction of big massive material, impact crusher and cone crusher will also be used for fine crushingFive stages of gypsum production process Stone Crusher In other words, gypsum crushers include jaw crusher, impact crusher and hammer crusher Today, Aimix will give you a detailed description of these machines gypsum raw material Performance Advantages of Gypsum Crusher: Aimix specializes in the production of all kinds of mobile crushers for more than 30 yearsTherefore, Aimix’s gypsum crusher Gypsum Crusher with High Quality and Large Capacity

Gypsum Crusher YouTube

Jun 01, 2010 The gipsum crusher of Ramliya II plant in EgyptIn this process gypsum is crushed, dried, ground, and calcined Not all of the operations shown in Figure 11161 are performed at all gypsum plants Some plants produce only wallboard, and many plants do not produce soil conditioner Gypsum ore, from quarries and underground mines, is crushed and stockpiled near a plant As1116 Gypsum Manufacturing US EPAJun 02, 2021 Hydraulic cone crushers are widely used in metal and nonmetal mines, cement plants, construction, sand and gravel metallurgy and other industries Since the cone crusher often works under heavy conditions and in a bad environment, it is very necessary to keep the lubrication system oil path unblocked, the oil is clean, does not leak, and runs normally, which is very necessary to ensure the Advantages of hydraulic cone crusher lubricationJiaozuo The 550T/hr processing plant is located centrally within lease area equidistant to the mining areas The processing plant incorporates a Primary Crusher rated at 1000T/hr (+201000mm), a secondary Sandvik cone crusher (250mm) and a Secondary Trio cone crusher (+250mm)Plant Kunooz GypsumKunooz GypsumFeb 06, 2019 Gypsum that comes from coal plants is called fluegas desulfurization gypsum, as it comes from the process that ‘scrubs’ sulfur out of the smoke stacks to reduce air pollution “The gypsum that is recovered has good quality,” says Dick “The gypsum particles are small and uniform in size making them quite reactiveGypsum as an agricultural product Soil Science Society

How Does Gypsum Remediate Saline And Sodic Soils?

Feb 01, 2014 Gypsum plays an important role in improving soil structure properties and soil will benefit from gypsum In these areas soils can be saline or sodic Salinity is the salt content in the soil and salts are the soluble nutrient ions in the soil solution and not on the soil’s cation exchange complexThe amount of gypsum you will need will depend on how you plan to use it and the conditions of your soil At USA Gypsum, we recommend conducting a soil analysis to ensure the addition of gypsum will benefit your plants USA Gypsum offers highquality, recycled gypsum for all your lawn and garden needs, shipped right to your doorHow Gypsum Can Help Your Garden Grow USA GypsumNov 06, 2017 Gypsum production plants vary widely in scale and level of technology They range from plants producing one or two tonnes per day using lowcost manual technologies, to plants of a thousand tonnes per day that are highly mechanized and capable of producing different types and grades of gypsum plaster or plaster boardsGypsum Production PlantThe gypsum crusher manages to crush the gypsum without creating paper contamination in the final gypsum product, so it can later be reused to make new plasterboards Adjustment to requirements A gypsum crusher can be adapted to the customer’s requirements so that the machine is supplied in the size that is most economical for the customer and Gypsum crusher from recycling and demolition waste Get How Does Gypsum Help in Plant and Soil Health? Here are some of the benefits of using gypsum for our garden: 1 It is a Good Source of Sulfur and Calcium Gypsum is a good source of calcium and sulfur which is essential for improved plant growth As time passes, plants are having less amount of sulfur which is essential in plant nutrition and enhancing crop harvestHow Much Gypsum Can You Add To Soil? Grower Today

How raymond mill works?

New style jaw crusher PE250X400, Chamber V structure with higher capacity Crawler mounted stone crusher, crawler mobile crushing plant Raymond roller mill inner instructure, YGM95 gypsum The gypsum crusher manages to crush the gypsum without creating paper contamination in the final gypsum product, so it can later be reused to make new plasterboards Adjustment to requirements A gypsum crusher can be adapted to the customer’s requirements so that the machine is supplied in the size that is most economical for the customer and Gypsum crusher from recycling and demolition waste Get Jul 12, 2016 Methods used in Crushing Screening Plants on ore range from a simple combination of a grizzly and one crusher to an elaborate arrangement in series of grizzly, jaw crusher, screens, and rolls or cone crushers Crushing is done underground at a few large mines In general, the jaw crusher is the most suitable primary machine, yet many gyratories do the first breakingCrushing Screening Plant 911 MetallurgistIn this process gypsum is crushed, dried, ground, and calcined Not all of the operations shown in Figure 11161 are performed at all gypsum plants Some plants produce only wallboard, and many plants do not produce soil conditioner Gypsum ore, from quarries and underground mines, is crushed and stockpiled near a plant As1116 Gypsum Manufacturing US EPAGypsum Mining Plant: Gypsum crushing and Gypsum grinding The process of Gypsum mining, and the other synthetic gypsum has been derived as a how gypsum is produced as a by product of mining Mining

Plant Kunooz GypsumKunooz Gypsum

The 550T/hr processing plant is located centrally within lease area equidistant to the mining areas The processing plant incorporates a Primary Crusher rated at 1000T/hr (+201000mm), a secondary Sandvik cone crusher (250mm) and a Secondary Trio cone crusher (+250mm)In a gypsum recycling system the gypsum is crushed and sorted in order to remove the impurities Afterwards you are left with gypsum powder, a raw material that is 100 % reuseable and ready to enter into the production of new plasterboards ReTec gypsum plant ReTec can deliever customized and dependable gypsym plants for shredding of recycled Gypsum recycling plants made by ReTec• Gypsum applied to acid soils can induce magnesium deficiency in plants on site; • Gypsum applied to sandy soils can depress phosphorus, copper and zinc transport; • Gypsum can have negative effects on mycorrhizal inoculation of roots, which may account forThe Myth of Gypsum Magic “Adding gypsum to your yard or Feb 06, 2019 Gypsum that comes from coal plants is called fluegas desulfurization gypsum, as it comes from the process that ‘scrubs’ sulfur out of the smoke stacks to reduce air pollution “The gypsum that is recovered has good quality,” says Dick “The gypsum particles are small and uniform in size making them quite reactiveGypsum as an agricultural product Soil Science Society Feb 01, 2014 Gypsum plays an important role in improving soil structure properties and soil will benefit from gypsum In these areas soils can be saline or sodic Salinity is the salt content in the soil and salts are the soluble nutrient ions in the soil solution and not on the soil’s cation exchange complexHow Does Gypsum Remediate Saline And Sodic Soils?

Raafat Elghamry Plant Manager Sahell Alaqeer gypsum

Work description: Acted as the general maintenance manager at gypsum plaster board plants, supervising and following up preventive maintenance programs and shutdown periods for maintenance, preparing the spare parts for the plants, which include both of a gypsum plant 1000 t/day, gypsum board plant 60000 m2/dayJan 14, 2019 The ancient Greeks named this form of gypsum “selenite” after their moon goddess, Selene, and the name has stuck all these years 4 Ben Franklin used gypsum on his farm Benjamin Franklin was the one of the first people in the United States to use gypsum He called it “land plaster” and put it to work on his farm to condition the soil5 Things You Didn't Know About Gypsum McLanahanIndustrial Hammermills are not limited to limestone or gypsum — they are known worldwide for processing bauxite, nickel ore, phosphate ore, coal, pet coke, clay, shale, and of course, limestone How Hammermill Crushers Work All Universal Hammermills work on three principal reduction methods: impact, shear and attritionHammermill Crushers McLanahandeposit Then gypsum ore is drilled and blasted loose to be carried to the processing plant, where it is crushed and screened The work is demanding, yet companies in the industry maintain excellent safety records In fact, on January 21,1990, Gold Bond’s Medicine Lodge mine and quarry operation marked its 16th year without a single lost How Gypsum is Made AWCIGypsum processing equipment differs significantly in scale and level of technology some plants produce one or two tonnes per day using lowcost manual technologies, some other plants of a thousand tonnes per day that are highly mechanized and capable of producing different types and grades of gypsum plaster or plaster boardsGypsum Mining Processing Equipment Flow Chart Cases

- carbon graphite resistant

- diesel Industria ginding mill

- cement grinding aid aditive chemicals

- grinder ver letter for resume

- Dry Washing Gold Processing Plants

- gold separator machine in red deer canada

- Health Tip Grinding Teeth During Sleep

- stone grinding mill spare parts Nigeria malaysiadesign

- crushing crusher model

- mining impact mills for sale

- 3d studio models free nveyor

- old mobile crusher plant for sale in netherlands

- pneumatic can crusher circuit figure

- jaw crusher out put 1 5mm ukuran pakan maks

- Ball Mill Untuk Kontrol Emas

- E traction Of Copper From Its Ore

- fob price gold ore super thin mill Dealer

- Dot Mining Mill De P 110

- jaypee sidhi cement plant address

- silver ore ultrafine grinding mill supplier

- used ball mills for sale in usa

- Stone Crusher In Maharashtra

- Belt Conveyor System To Cement Silo Drawing

- Hydraulic Stone Crushing Equipment

- free video elektrolisis for gold

- mining equipment builders

- New Minerals Aggregate Vibrating Screen Vietnam

- silica ncentrator for graphite mine in chile

- belt grinding hand machinesstone

- zimbabwe rotation impact crusher supplier