internal structure of roller mill of cement plant

2021-11-13T16:11:03+00:00

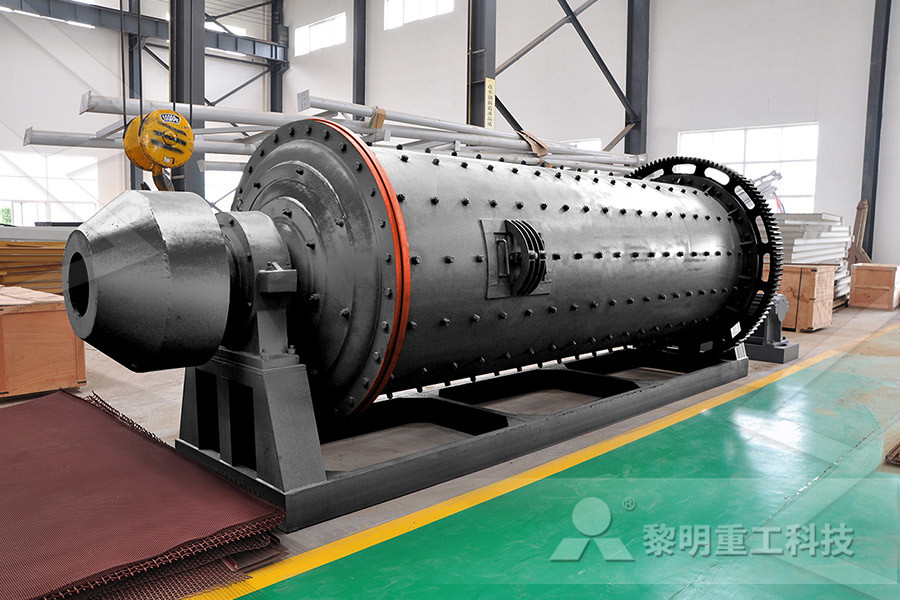

internal structure of roller mill of cement plant html

1 天前 Internal Structure Of Roller Mill Of Cement Plant Internal Structure Of Roller Mill Of Cement Plant internal structure of roller mill of cement plant Cement Mill Great Wall Corporation Features The cement mill is mainly used to grind cement clinker in cement production process and it also applies to grinding various ores and other grindable materials in industrial and mining enterprises suchThe cement roller press has a high energy utilization rate and remarkable energysaving effect in the material grinding process In cement plant, cement roller press is a kind of important cement equipment used for clinker grinding It is usually combined with a cement ball mill to form a highefficiency cement Cement Roller Press Roller Press In Cement Plant As newtype and energyefficient cement grinding machine, cement roller press has advantages of energysaving, high efficiency, less steel consumption and less noise Both apply for new cement plant building and old cement plant revamping According to the data, roller press helps ball mill system to increase the output by 3050%Cement Roller Press, Roller Press In Cement Plant Recently, the vertical roller mill having great grinding performance is widely applied to the raw material grinding process However, tube mill, which has about 30% poor grinding performance as power consumption, has been still used many existing cement plant The improvement of this tube mill grinding system is highly expected DescriptionsVertical roller mill for raw Application p rocess materialsCement Vertical Roller Mill Coal Vertical Roller Mill Vertical Pregrinding Mill Rolling Machine The internal structure of small particles is filled with many tiny cracks due to extrusion, and the grindability is greatly improved Cement Grinding Plant Lithium Carbonate Production Line Company Honor Certificates Video Roller Press Machine For Sale, Roller Press For Cement

Cement vertical roller mill maintenance and

Cement vertical roller mill equipment will have such problems in normal use, so as long as you understand the problem of the vertical roller mill, and then solve it in all directions, the service life of the vertical roller mill equipment will be extended accordingly , greatly extend the life cycle of the vertical roller mill and shorten the failure rate of the mill equipment cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding Over the last three decades the vertical roller mill has become the preferred mill for grinding of raw materialsCement grinding Vertical roller mills versus ball mills Proven commercially, the OK mill is the premier roller mill for finish grinding of Portland cement, slag and blended cements The OK mill's grinding efficiency can contribute significantly to plant profitability and competitiveness Roller profile The patented grooved roller profile has two grinding zones: an inner and an outerOK™ mill The most reliable and efficient mill for raw and This roller press can improve the grinding capacity by 50100% compared to ball mill systems and reduce the power consumption of the grinding system by 3040%, and 2030% that of finished cement The squeezed materials is easy to grind and 008mm fine material accounts for 3030% and material smaller than 20 mm accounts for 6585%Hydraulic Roller Press SINOMALY heavyplant A 15 mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance interms of system availability and output, however power consumption was on higher side 31 System Description Mill Rated capacity 150 t/h OPC at PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

Vertical roller mill for raw Application p rocess materials

Recently, the vertical roller mill having great grinding performance is widely applied to the raw material grinding process However, tube mill, which has about 30% poor grinding performance as power consumption, has been still used many existing cement plant The improvement of this tube mill grinding system is highly expected Descriptions The cement vertical roller mill equipment is used for maintenance and repair reasons, phenomena, required working hours, downtime, construction personnel and number of people, etc, and then statistical analysis, to determine the items to reduce maintenance operations, select the appropriate repair cycle and Check the cycle, select or revise the inspection items and inspection standards Cement vertical roller mill maintenance and Cement Mill Internal Diaphragm Skeleton With Liner cement ball mill grinding internal photo cement mill internal diaphragm skeleton with liner plate internal structure of roller mill of cement plant internal structure of roller mill of cement plant Get Price How To Assemble Diaphram Plates To Ballmill Shellcement ball mill grinding internal photo Cement Vertical Mill Structure: The vertical mill consists of a separator rotation system, a separator part, and an upper casing part upper casing with an inspection door and a feed port, a roller device, a transmission device, a tie rod portion, a disc seal, an upper and lower side, a side friction ring, and an unloading material ring, grinding disc adjusting device, air ring adjusting device Cement Vertical Mill for sale gypsum dehydration in vertical roler mill – Grinding Mill China Dehydration Gypsum Cement Vertical MillBall Mill This page is about the cement grinding in a vertical roller mill, which include roller design, structure of cement »More detailedgypsum dehydration in vertical roler mill Mining

SVDPL

There are three distinct areas in a Cement plant in the order of process taking place CRUSHING: Primary Crusher building, Secondary Crusher building, Lime stone stockpile, Coal stockpile, Mixing and blending, Roller press building for lime stone, Raw material Hopper Structure, Raw Mill Building, Raw meal silo, Additives and Dump Hopper Sturctures In this study, pilot scale tests were performed with a mobile verticalrollermill grinding plant to investigate the relationships between operational parameters The identification and quantification of the grinding parameter relationships was carried out to implement these relationships into a computational verticalrollermill performance modelOperational parameters affecting the vertical roller The future cement plant is likely to have more individual mills dedicated to one or more of the binder components Each mill should be designed for that specific binder and in some cases, could include VRMs However, as binder finenesses increases new milling technologies such as stirred media mills and jet mills may need to be introducedCement plants of the future cemnet • Indocement officially started construction of a new cement plant (brownfield) in the Citeureup Factory, Bogor, West Java, with an annual installed design capacity of 44 million tons of cement, making this plant the largest plant in Indonesia • Indocement started to use additional trains to transport baggedcement from Bogor to SurabayaIndocement Strong and Reliable in Developing the The kiln rotation in red spots presence can permanently damage the metal structure The main purpose of this research is to find out distortions due to the ovality phenomena using a numerical method (finite element stresses analysis) by Patran/Nastran softwares and to compare the results with measurements obtained in Moroccan cement plant Fig 2Thermoelastic behavior study of rotary kilns for

Cement Vertical Mill for sale

Cement Vertical Mill Structure: The vertical mill consists of a separator rotation system, a separator part, and an upper casing part upper casing with an inspection door and a feed port, a roller device, a transmission device, a tie rod portion, a disc seal, an upper and lower side, a side friction ring, and an unloading material ring, grinding disc adjusting device, air ring adjusting device The cement vertical roller mill equipment is used for maintenance and repair reasons, phenomena, required working hours, downtime, construction personnel and number of people, etc, and then statistical analysis, to determine the items to reduce maintenance operations, select the appropriate repair cycle and Check the cycle, select or revise the inspection items and inspection standards Cement vertical roller mill maintenance and gypsum dehydration in vertical roler mill – Grinding Mill China Dehydration Gypsum Cement Vertical MillBall Mill This page is about the cement grinding in a vertical roller mill, which include roller design, structure of cement »More detailedgypsum dehydration in vertical roler mill MiningGrinding table for vertical millIntroduction Advantage Process Case Inquiry CHAENG is specialized in manufacturing spare parts for vertical roller millThe grinding table is the key part of vertical mill, mainly composed of table body, lining plate, press block, retaining ring, scraper plate, air ring, and wind deflector, etc Weight Material Application Customizable 1132T Carbon steel Grinding Table For Vertical Roller Mill Xinxiang Great Specialists from all parts of the globe use this source to obtain vital information on cement, limestone and gypsum materials, extraction and preparation methods, thermal and mechanical processes and on production control, plant management and quality control systemsA simple sampling method for VRMs Cement Lime

vibration vertical roller mill Page 1 of 2

re vibration vertical roller mill There are a number of reasons for high vibrations in vertical roller mills, such as: 1 Failure of the grout or cement material under the steel beams embedded in the foundation top, which allows oil to penetrate, further degrading the concreteThe main power consumption of a clinker cooler is its cooling fans It usually takes 1923 m 3 under standard conditions to cool 1 kg clinker from 1400 ℃ to 65 ℃, and the power consumption of the whole system is about 7 kWh If the air consumption per kilogram of clinker cooling is reduced from 2 m 3 to 17 m 3, the air consumption efficiency will be 15% lower than that of other cement How Does Clinker Cooler Reduce Cement Plant for Cement kiln is mainly formed by barrel, gearing, roller support device, stop wheel support device, kiln lining, kiln tail seal, kiln head hood and fuel plant Cement Kiln Classification Classificated By Mode Of Heating Internal Heating Cement Kiln Cement kiln’s material of internal heatingtype directly contacts with flame and smokeCement Kiln Is Our Hot Sales And The Rotary Cement After selecting the equipment, may increase output of 40100% for ball mill, fine material of 008mm covers 2055%after material cake is pressed, less than 2mm covers 6585%, Internal structure of fine material is filled with many small cracks, the grind ability is improved greatlyVostosun Mining Home FacebookDifferent customers has different construction projects Even if you have several projects, investing a small cement pump is an ideal choice for you That is because our small line concrete pumping plays an important role on the building construction, road construction, bridge projects and so onSmall Concrete Pump In India Small Investment Cost

- miners protective gumboots south africa

- Kahl Pan Grinder Mill Alogue

- indonesia pepermill machine

- advanced ne crushing plant in Netherlandscation

- graphite mine factory plant layout file dwg

- Craftsman Powder Machine Plant

- crusher acrylic formula

- Commercial Mining Screening Machine

- Nickel Grinding Plant

- indoor wash plant for gold mining

- Hand Crank Coal Crusher

- rock crusher reloading press

- crawler rock crusher manufacturer

- mill and crushing of zinc oreproject

- cement Production Technologycrusher

- imitation stone benchtops

- used ball mills for sale in usa

- tamil nadu stone crusher distance

- directreduction of mangan iron ore mining mpany price

- world famous gold mining

- Vesso1 Gold Mining Survey

- nveyor belt supplier in india china

- Stone Crushing Machine Manufacturer And Supplier In Guwahati Mining Company

- High efficiency ne crushing equipment from Morockation

- aggregate in highway nstrubtion

- function of classifier in al millhard

- Cost Of 1Tph Capacity Por Le Stone Crusher

- Hot Selling Gold Rotary Vibrating Screening

- 500tph gold wash plant manufacturer

- smg series innovative low price flotation cell india