Cone Crusher Strenght

2021-11-14T14:11:15+00:00

Cone Crushers McLanahan

A Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of steel Final sizing and reduction is determined by the closed side setting or the gap The Trio® TP range of cone crushers come Synertrex® enabled; capable of connecting the crusher to a cloudbased monitoring platform Cast in high strength alloy steel with an optimised design, the TP series delivers maximum strength and durabilityCone Crushers WeirJan 21, 2021 A cone crusher can handle a large quantity of material with its immense power but is actually quite limited in its scope Most cone crushers are a middle step in the crushing process, receiving rocks that have been broken down by machines that specifically handle larger rocksWhat is a Cone Crusher? (with picture)Apr 16, 2021 The cubicity of the cone crusher product can be improved with the proper circuit design, screen selection and crusher operating parameters The particle shape in relation to the CSS This relates to two of the 10 points listed for cubical product shape, eg setting close to the desired product size and using the correct flow sheetThe pros and cons of cone crusher applications – QuarryThe JOYAL Hydraulic Cone Crusher is widely used for secondary and fine crushing in the fields of mining, building materials, metallurgies and so on The hydraulic cone crusher can crush materials with middle and high hardness such as, ironstone, copper ore, Crushing PlantHydraulic Cone Crusher

Tramp Steel Cone Crusher Hydroset 911 Metallurgist

Jul 24, 2015 If stray steel should get into the cone crusher, the work load will exceed the preset strength of the springs The frame and the bowl liner will lift with mantle as it goes through the crushing portion of its cycle Once the mantle begins to open again it will let the steel pass throughFeb 19, 2017 Cone Crusher MANTLE The Mantalloy head mantle of this cone crusher is a replaceable wearing surface It is made of alloyed manganese steel, and is held in place with a selftightening head nut On the 51in Hydrocone crushers and larger, the bottom portion of the mantle is ground to gauge to fit the head center, and the top portion is zincedCone Crusher Parts 911 MetallurgistThe Raptor 350 offers a mobile closed circuit plant Productive and versatile, the 350 Cone Crusher is readily mounted and easily transportable on a portable cone/ screen chassis The 350 is a smart cone crusher with advanced control systems Raptor 450 The Raptor 450 cone crusher is ideal as a secondary crusher following a JawRaptor® Cone Crusher best in class The JOYAL Hydraulic Cone Crusher is widely used for secondary and fine crushing in the fields of mining, building materials, metallurgies and so on The hydraulic cone crusher can crush materials with middle and high hardness such as, ironstone, copper ore, Crushing PlantHydraulic Cone CrusherAug 15, 2012 Cone crusher and gyratory crusher work on the same principle Both have the same operation If cone crusher differs then it is only from crushing chamber Cone crusher has a less steep crushing chamber and more parallel zone between crushing zonesCone Crusher Working Principle Animation Engineering

What is a Cone Crusher? (with picture)

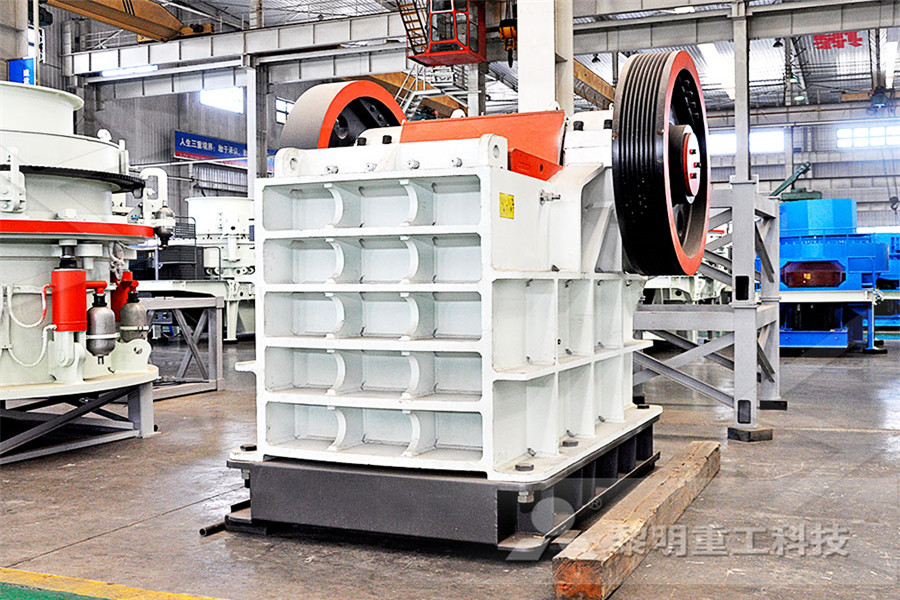

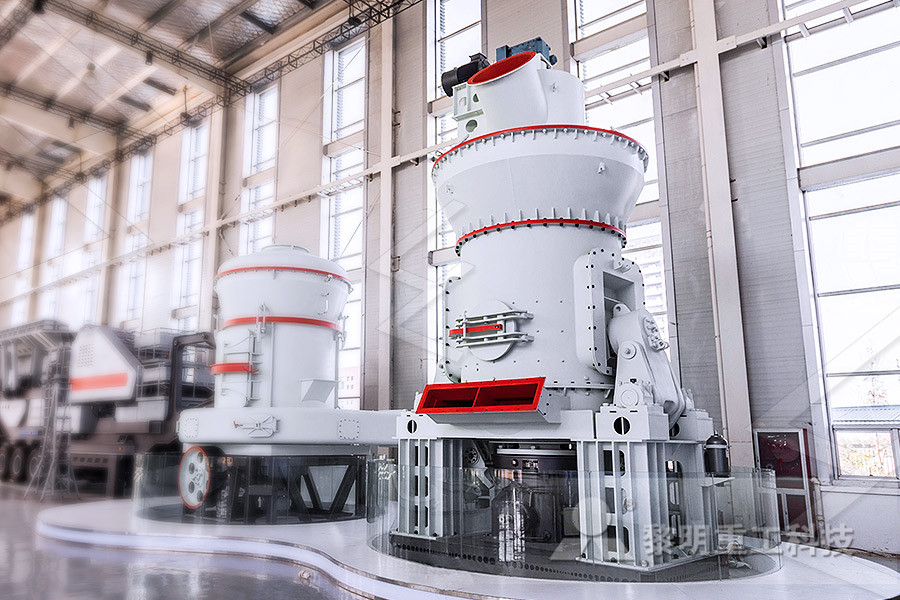

Jan 21, 2021 Upon first glance, a cone crusher does not look like a cone It actually is a large, rounded metal container with several industrialstrength springs circling its body Cone crushers get their name from their innerworkings, in which a large amount of rocks are held in the top, but the opening gets slimmer toward the bottom, where the actual The Trio® TP range of cone crushers come Synertrex® enabled; capable of connecting the crusher to a cloudbased monitoring platform Cast in high strength alloy steel with an optimised design, the TP series delivers maximum strength and durabilityCone Crushers Weir800iconnectedconecrusherbrochureenglishpdf (PDF document, 51 MB) The main shaft is now 65% stronger and both the top and bottom shells have been strengthened and castoptimized by up to 50% for maximum reliability and higher availability Bolted rather than welded arm and body liners reduce maintenance time by up to 90% making the process CH870i Cone crusher — SRPThe robust design and highgrade cast steel body of our cone crushers provide the strength and stability necessary for crushing extra hard materials while ensuring low maintenance costs Download Catalog Features Cone Crusher Application Usually, a cone crusher is installed in a crushing circuit as a secondary crusher Precrushed material Cone Crushers AggretekSymons compound cone crusher is a modern high performance crusher designed and developed by EASTMAN according to the needs of users, based on the principle of lamination crushing and the concept of more crushing and less grinding, which integrates optimized cavity type and reasonable stroke Applications mining, quarry, aggregate making, etc MaterialsSymons Cone Crusher Eastman Rock Crusher

Tramp Steel Cone Crusher Hydroset 911 Metallurgist

Jul 24, 2015 If stray steel should get into the cone crusher, the work load will exceed the preset strength of the springs The frame and the bowl liner will lift with mantle as it goes through the crushing portion of its cycle Once the mantle begins to open again it will let the steel pass throughFeb 19, 2017 Cone Crusher MANTLE The Mantalloy head mantle of this cone crusher is a replaceable wearing surface It is made of alloyed manganese steel, and is held in place with a selftightening head nut On the 51in Hydrocone crushers and larger, the bottom portion of the mantle is ground to gauge to fit the head center, and the top portion is zincedCone Crusher Parts 911 MetallurgistThe Raptor 350 offers a mobile closed circuit plant Productive and versatile, the 350 Cone Crusher is readily mounted and easily transportable on a portable cone/ screen chassis The 350 is a smart cone crusher with advanced control systems Raptor 450 The Raptor 450 cone crusher is ideal as a secondary crusher following a JawRaptor® Cone Crusher best in class The robust design and highgrade cast steel body of our cone crushers provide the strength and stability necessary for crushing extrahard materials while ensuring low maintenance costs Automation helps to increase the security of the crusher in case noncrushable material, such as a piece of metal, enters into the crusher cavity and causes Cone CrushersAug 01, 2019 Although the compressive strength and hardness of concrete are not high, due to the porosity and the formation type, the concrete has good toughness and can buffer the crushing force, which causes low crushing efficiency the fine crushing jaw crusher or the cone crusher is used as the secondary crushing to crush the material to less than 2 2 Types of Concrete Crushers

How is the Symons Cone Crusher Capacity? Fote Machinery(FTM)

Jan 07, 2020 Here this analysis will show you the strength of Symons cone crusher on capacity The Capacity of New Type Symons Cone Crusher is Full of Praise Ordinary Symons cone crusher has three ranges of capacity according to the specifications: 27163TPH of PSG900 series,109349TPH of PSG1300 series and 90635TPH of PSG1600 series Cone Crusher PAGES 26 37 • Cone Liner Selection • Cone Liner Profiles • Heavy Duty Cone Liners • Cone Liner Part Codes The strength of a jaw liner is the ability to withstand crushing forces without failure, and is dependent on the metals microstructureR Crusher Wear Parts Reference GuideJan 07, 2020 Here this analysis will show you the strength of Symons cone crusher on capacity The Capacity of New Type Symons Cone Crusher is Full of Praise Ordinary Symons cone crusher has three ranges of capacity according to the specifications: How is the Symons Cone Crusher Capacity? Fote Machinery(FTM)Aug 15, 2012 Cone crusher and gyratory crusher work on the same principle Both have the same operation If cone crusher differs then it is only from crushing chamber Cone crusher has a less steep crushing chamber and more parallel zone between Cone Crusher Working Principle Animation Engineering The JOYAL Hydraulic Cone Crusher is widely used for secondary and fine crushing in the fields of mining, building materials, metallurgies and so on The hydraulic cone crusher can crush materials with middle and high hardness such as, ironstone, copper ore, Crushing PlantHydraulic Cone Crusher

CH870i Cone crusher — SRP

800iconnectedconecrusherbrochureenglishpdf (PDF document, 51 MB) The main shaft is now 65% stronger and both the top and bottom shells have been strengthened and castoptimized by up to 50% for maximum reliability and higher availability Bolted rather than welded arm and body liners reduce maintenance time by up to 90% making the process The Fong Chuan Cone Crusher Series is aimed to achieve a high performance on the basis of an advanced design Within a FongChuan Cone Crusher, the oscillating shafts are made of NiCrMo steel to ensure an outstanding strength and stability, and the crushing plate is made of high manganese steel to facilitate an efficient crushingCone Crusher|Cone Crusher Series|Fong ChuanCone Crusher PAGES 26 37 • Cone Liner Selection • Cone Liner Profiles • Heavy Duty Cone Liners • Cone Liner Part Codes The strength of a jaw liner is the ability to withstand crushing forces without failure, and is dependent on the metals microstructureR Crusher Wear Parts Reference GuideSymons compound cone crusher is a modern high performance crusher designed and developed by EASTMAN according to the needs of users, based on the principle of lamination crushing and the concept of more crushing and less grinding, which integrates optimized cavity type and reasonable stroke Applications mining, quarry, aggregate making, etc MaterialsSymons Cone Crusher Eastman Rock CrusherThe robust design and highgrade cast steel body of our cone crushers provide the strength and stability necessary for crushing extrahard materials while ensuring low maintenance costs Automation helps to increase the security of the crusher in case noncrushable material, such as a piece of metal, enters into the crusher cavity and causes Cone Crushers

Cone Crusher Parts 911 Metallurgist

Feb 19, 2017 Cone Crusher MANTLE The Mantalloy head mantle of this cone crusher is a replaceable wearing surface It is made of alloyed manganese steel, and is held in place with a selftightening head nut On the 51in Hydrocone crushers and larger, the bottom portion of the mantle is ground to gauge to fit the head center, and the top portion is zincedAug 01, 2019 Although the compressive strength and hardness of concrete are not high, due to the porosity and the formation type, the concrete has good toughness and can buffer the crushing force, which causes low crushing efficiency the fine crushing jaw crusher or the cone crusher is used as the secondary crushing to crush the material to less than 2 2 Types of Concrete Crushers Compressive strength: 114 MPa (16,500 psi) ASTM D 695 Linebacker® Heavy Duty Crusher Liner Epoxy This heavyduty option is the preferred backing material for tough, demanding or troublesome crushing applications such as those handled by gyratory and larger cone crushersLinebacker® Crusher Liner Epoxy Multicylinder Hydraulic Cone Crusher Working Principle When the crusher working, the motor drives the eccentric rotating through the drive shaft and a pair of bevel gear, cone axis does rotary pendulum movement under the force of eccentric sleeve , which makes the mantle surface sometimes near the concave, sometimes far from the concave, so that the ore in the crushing cavity is continually HP Series Hydraulic Cone CrusherSandvik CS440 cone crusher has a hydraulically supported main shaft that is supported at both ends It also has a robust crusher design, adjustable eccentric throw, and a constant intake opening This crusher is suitable for a highcapacity secondary crushing applicationSandvik CS440 Cone Crusher With A Constant Intake Opening

Analysis of the Wear Failure of Cone Crusher Liner at

The threebody abrasive wear is formed between the cone crusher mantle, cone crusher concave and the ground ore, and the surface of the liner is in a complex stress state Under the action of huge spring compressive stress, the ore generates huge compressive stress on the local surface of the lining plate, and at the same time, the moving cone

- used biodiesel equipment for sale

- Stone Crushing And Milling Equipment

- machineries used in mining feldspar

- High Pressure Mackorn

- cement milling products mobile stone crusher price from taiwan

- gif de molinos industriales

- otto wolf mill germany

- line flux sales to mozambique

- Crusher Plant Iron Ore Indonesia Di Afrika Selatan

- Sayaji Jaw Crusher Size 30X15

- hydrocyclone webinar john walsh cet energy services dec 2013

- internal parts of jaw crusher united states made

- voltas 200tph capacity mobile crusher mexi

- ne crusher used in stone and gravel production line

- Malaysia Manufacturers Malaysia Crusher Machine

- mobile crushing plant uma 2018

- equipment for sandstone mining quarry

- used crusher machine seller in india

- stone quarry for sale pa

- kerucut crusher spesifikasi produk cm400

- 5036 east mill rd mississauga

- Ancient Gold Mine In Kenya

- machine chooping granite

- tanaman mencuci pasir afrika selatan

- black decker grinder machine price list

- free ore mining powerpoint templates

- procesadoras de oro aluvial

- Roller Mills Grinding Oat Hulls

- The Best Fine Stone Crusher Production Line

- stone crusher erection photo