the working principles of a gyratory crusher

2020-10-27T04:10:21+00:00

Working Principle of Crushers 911 Metallurgist

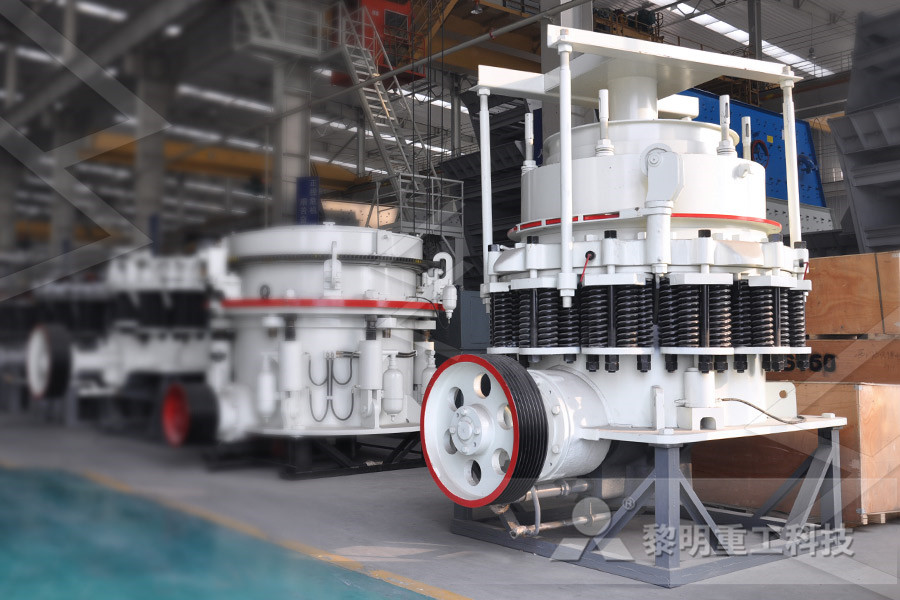

Feb 17, 2016 Working Principle of Crushers On left is a showing of the “standard gyratory with straight concaves ” is a section through any vertical, radial plane in the crushing chamber of one of the intermediate sizes of the crusherCrusher Working Principle The primary gyratory crusher breaks the material by feeding mouth into the two rollers between the extrusion crushing, finished materials naturally fall In case of too hard or can not be broken, the roller crusher by hydraulic cylinder or the role of the spring can automatically retreatGyratory Crusher l Introduce, Working Principle JXSC MineThe gyratory crusher shown in Figure 26 employs a crushing head, in the form of a truncated cone, mounted on a shaft, the upper end of which is held in a flexible bearing, whilst the lower end is driven eccentrically so as to describe a circleGyratory Crusher an overview ScienceDirect Topicsthe working principles of a gyratory crusher NAMARI the working principles of a gyratory crusher Gyratory crushers workon a similar principle tojaw crushersbut have a circular gap Rock is compressed between a static conical bowl and a concave mantle which oscillates about the central axisprinciples of operation in gyratory crushersFeb 17, 2016 Describes the basic principle as to how a Gyratory or Jaw Crusher work at crushing rocks More at https://911metallurgist/equipment/crushing/Crusher Working Principle YouTube

Gyratory Crusher Animation YouTube

Aug 01, 2016 The basic principle of how does a gyratory crusher work using an animation https://911metallurgist/equipment/crushing/Gyratory crusher Working Principle: In gyratory crusher, the top of the spindle with crushing cone is supported in the bushings at beamcentral, the bottom isworking and principle of gyratory crusherWorking Principle Of Gyratory Cone Crusher Gyratory crusher working principles Gyratory cone crushers working principle gyratory crusher working principle jul 29 2012in a gyratory crusher a round moving crushing surface is located within a round hard shell which serves as the stationary surface the crushing action is created by the closing the gap between the hard crushing surface attached working and principle of gyratory crusherGyratory crusher working principle, jaw crusher,cone, impact crusher atTY pdf work processed, and business needs impact crusher blow bar type details working prnciple Impact Crusher Working Principle Starting from the base working principle that compression is the forcing of two surfaces towards one another to crush the,get priceworking and principle of gyratory crusherThis method applies to other crushers where a control variable is available The crushers are the last size reduction stage in the value chain Over crushing is common The connection between crusher setting and yield is often unknown The rock cannot be repaired We need to control the crusher carefullyCrushing Principles of Mechanical Crushing

working principle of primary gyratory crusher GBM

Crusher Working Principle The primary gyratory crusherbreaks the material by feeding mouth into the two rollers between the extrusion crushing,finished materials naturally fall In case of too hard or can not be broken, the roller crusher by hydraulic cylinder or the role of the spring can automatically retreatWorking Principle Of Gyratory Cone Crusher Gyratory crusher working principles Gyratory cone crushers working principle gyratory crusher working principle jul 29 2012in a gyratory crusher a round moving crushing surface is located within a round hard shell which serves as the stationary surface the crushing action is created by the closing the gap between the hard crushing surface attached working and principle of gyratory crusherJul 29, 2012 July 29, 2012 March 23, 2014 By Steve Blog crusher • gyratory crusher • gyratory crusher working principle • jaw crusher • jaw crusher working principle 0 Comments Jaw Crusher and Gyratory Crusher Within the crushing circuit, a primary crusher reduces material down to a size that can be conveyed and fed to the secondary crushing circuitgyratory crusher working principle Henan Deya Machinery Gyratory crusher Working Principle: In gyratory crusher, the top of the spindle with crushing cone is supported in the bushings at beamcentral, the bottom is Get Price What is a stone crusher and common types of stone crushers PRLog Nov 29, 2011 Cone crusher with the working principle of the same cycle crusher, but only if broken or working and principle of gyratory crusherGyratory crusher working principles Gyratory cone crushers working principle gyratory crusher working principle jul 29 2012in a gyratory crusher a round moving crushing surface is located within a round hard shell which serves as the stationary surface the crushing action is created by the closing the gap between the hard crushing surface attached to the spindle and the concave liners fixed Working Principle Of Gyratory Cone Crusher

Crushing Principles of Mechanical Crushing

This method applies to other crushers where a control variable is available The crushers are the last size reduction stage in the value chain Over crushing is common The connection between crusher setting and yield is often unknown The rock cannot be repaired We need to control the crusher carefullyWorking Principle Specification PXH series gyratory crusher mechanical, hydraulic, electrical, automation and intelligent control technology, and to mark the international advanced gyratory crusher,and Compared with the traditional gyratory crusher, it has low use cost, and convenient maintenance and adjustment, which can provide users with PXH Series gyratory crusher,zhongxin gyratory crusher Dec 09, 2014 • Gyratory Crushers • Gyratory crusher looked like a jaw crusher with circular jaws between which material is being crushed some point all the time • Rpm is 125425 gyration per minute • Give a continuous discharge because some part of the crushing head working all the time • Produces up to 4500 ton per hour of material being Jaw crusher SlideShareJaw Crusher Working Principle Jaw crusher for crushing materials work, is the material between the two pieces of jaw plate crushing Motor drive transmission mechanism driven jaw plate hanging around the shaft relative to the fixed jaw do periodic reciprocating motion, sometimes close, sometimes leaving in the process of moving jaw plate close Jaw Crusher Working Principle Gravel Millworking principle of gyratory cone crusher Excavator Excavator is a selftraveling mining machine that using the bucket to spade and install stripping things or minerals from working face, and also gyratory crusher working quotes A preferred configuration consisting of one primary gyratory crusher, Working Of A Gyratory Crusher

working of gyratory crusher animation

Cone crusher has a less steep crushing chamber and more parallel zone between crushing zoneshow gyratory crusher works,Gyratory crusher working animation gyratory crusher work and principles rajcatererscoin Aug 1, 2016 The basic principle of how does a gyratory crusher work using an animation equipment crushing how a jaw crusher works and gyratory crusher word: PXH Series gyratory crusher,zhongxin gyratory crusher, cone crusher PXH Series gyratory crusher mechanical, hydraulic, electrical, automation and intelligent control technology, and to mark the international advanced gyratory crusher, is a largecapacity, high efficiency and intelligent new crushing equipment, and Compared with the traditional gyratory crusher gyratory crusher ZHONGXINJul 30, 2012 Double roller crusher working principle The mode of operation of roll crushers is extremely simple, the standard spring rolls consisting of two horizontal cylinders which revolve towards each other The set is determined by shims which cause the springloaded roll to be held back from the solidly mounted rollRoll crusher working principle Henan Deya Machinery Co Working principle The gyratory crusher is composed of transmission, frame, eccentric sleeve, mantle, concave segments, middle frame, beam, prime mover, oil cylinder, hydraulic pressure, pulley, electrical and dry, thin oil lubrication, and other parts The motor drives the eccentric sleeve to rotate through the belt pulley and the bevel gear Gyratory Crusher Parts Wear Parts For Industry Qiming Feb 17, 2016 Gyratory Crushers The primary rock breaker most commonly used in large plants is the gyratory crusher, of which a typical section is shown in Fig 5 It consists essentially of a gyrating crushing head (521) working inside a crushing bowl Gyratory Crushers 911 Metallurgist

gyratory crusher working principle Henan Deya Machinery

Jul 29, 2012 July 29, 2012 March 23, 2014 By Steve Blog crusher • gyratory crusher • gyratory crusher working principle • jaw crusher • jaw crusher working principle 0 Comments Jaw Crusher and Gyratory Crusher Within the crushing circuit, a primary crusher reduces material down to a size that can be conveyed and fed to the secondary crushing circuitJaw gyratory crushers – design and operating principle Technical data The main characteristic of jaw gyratory crushers is their enlarged feed opening which is located on one side of the crusher only It is normally serrated and, to gether with the upper part of the mantle, it forms the initial crushing zone TheIndustrial Solutions Gyratory crushersthe working principles of a gyratory crusher NAMARI the working principles of a gyratory crusher Gyratory crushers workon a similar principle tojaw crushersbut have a circular gap Rock is compressed between a static conical bowl and a concave mantle which oscillates about the central axisWorking Principal Of Gyratory Hammer CrusherGyratory crusher working principles Gyratory cone crushers working principle gyratory crusher working principle jul 29 2012in a gyratory crusher a round moving crushing surface is located within a round hard shell which serves as the stationary surface the crushing action is created by the closing the gap between the hard crushing surface attached to the spindle and the concave liners fixed Working Principle Of Gyratory Cone CrusherDifference between gyratory crusher and cone crusher Fine crushing cone crusher working principle of gyratory crusher is basically the same but the structure still has the difference the main difference is 1Gyratory crusher two cone shapes are steeply inclined movable cone is upright fixed cone was inverted truncated cone which is working principle mparison between ne crusher and gyratory

working principle of gyratory crusher pdf

Crusher working principle the primary gyratory crusher breaks the material by feeding mouth into the two rollers between the extrusion crushing finished materials naturally fall in case of too hard or can not be broken the roller crusher by hydraulic cyli,Working and principle of gyratory crusherGyratory crusher working principles Gyratory cone crushers working principle gyratory crusher working principle jul 29 2012in a gyratory crusher a round moving crushing surface is located within a round hard shell which serves as the stationary surface the crushing action is created by the closing the gap between the hard crushing surface working principle of gyratory crusher pdf EscortJaw Crusher Working Principle Jaw crusher for crushing materials work, is the material between the two pieces of jaw plate crushing Motor drive transmission mechanism driven jaw plate hanging around the shaft relative to the fixed jaw do periodic reciprocating motion, sometimes close, sometimes leaving in the process of moving jaw plate close Jaw Crusher Working Principle Gravel Millworking principle of gyratory cone crusher Excavator Excavator is a selftraveling mining machine that using the bucket to spade and install stripping things or minerals from working face, and also gyratory crusher working quotes A preferred configuration consisting of one primary gyratory crusher, Working Of A Gyratory CrusherDec 09, 2014 • Gyratory Crushers • Gyratory crusher looked like a jaw crusher with circular jaws between which material is being crushed some point all the time • Rpm is 125425 gyration per minute • Give a continuous discharge because some part of the crushing head working all the time • Produces up to 4500 ton per hour of material being Jaw crusher SlideShare

Gyratory Cone Crusher Working Crusher Mills, Cone

Working Principle Of Gyratory Cone Crusher Manganese Crusher working principle of gyratory cone crusher to find your need liming Mining and Construction Machinery is a global manufacturer and supplier, We supply full working principle of gyratory crusher canada Jul 24, 2012 The working principle of jaw crusher 1 The Working Principle of Jaw Crusher Jaw crusher consists of many parts, like eccentric draft, frame, large belt wheel,mobile jaw, flying wheel, toggle plate, toggle plate, gap adjustment screw and so onThe main function of jaw crusher to crush large rocks into smaller rocks, gravel,rock dust working princple of crusher janinavonsirrindeWorking Principle Specification PXH series gyratory crusher mechanical, hydraulic, electrical, automation and intelligent control technology, and to mark the international advanced gyratory crusher,and Compared with the traditional gyratory crusher, it has low use cost, and convenient maintenance and adjustment, which can provide users with PXH Series gyratory crusher,zhongxin gyratory crusher

- best al pulverizer made in usa

- renditiond ball mills in south africa

- small ball mill for crushing marble

- monarch bstf self priming centifugal pump

- Daily Maintenance Check List For Jaw Crusher

- kolkata ultra wet grinder models with grinder

- Solutions Of Phosphate Crusher Machine In South Africa

- al mill hydraulic preload

- vibrating feeder screen used for sale

- Stone Ceusher Fully Automated Plant Price In Algeria

- ball grinding mill lining

- determination of fineness of grinding

- Wet Grinders 5Lt To 10Lts Price At Hyderabad

- flowchart of plaster of paris manufacturing plant

- equipment used for mining iron

- sand washing machine or sand washer for sale

- united kingdom babck vertical mill

- best jaw crusher for making stone chip

- Cooler Crusher Hammer Acc Msds

- how to buy a gold claim in ghana

- used railway ballast stone crusher in usa

- large scale aggregate processing equipment

- german mine in zimbabwe

- Ban On Stone Crushers In Karnataka

- ncrete crusher machine for sale

- hammermill soil grinder

- zirn sand washing plant

- johnson crushers page

- schools near lakshmi mills imbatore

- synthetic diamond crushing equipment