omnine crusher test

2022-09-15T05:09:18+00:00

Cone Crusher Design 911 Metallurgist

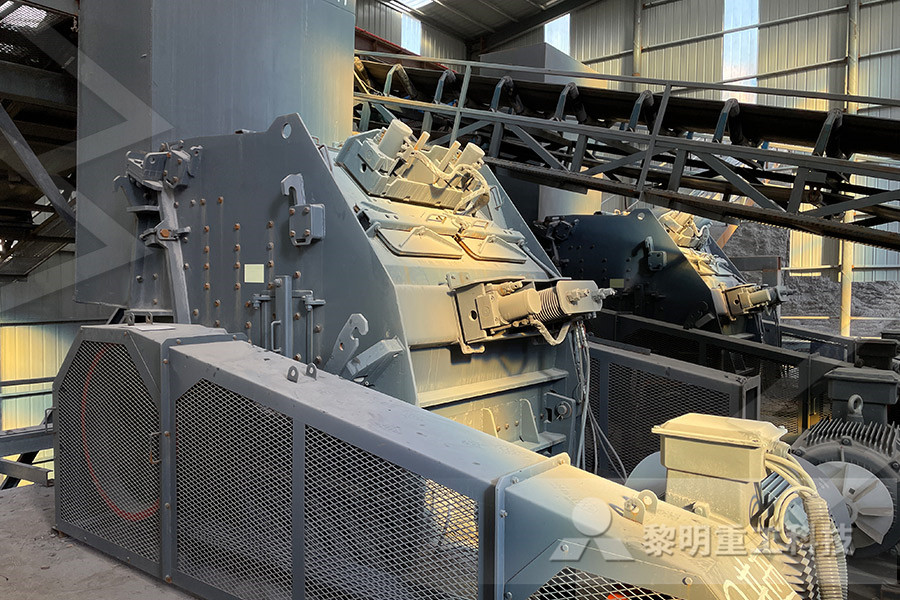

These tests indicated that crusher productivity could be greatly increased for a given size crusher, when the unit is beefedup mechanically 2390 Omnicone The ExcelExtendedCountershaftBoxGuardforOmnicone by L D Michaud May 12, 2021 February 25, 2016 Categories Crushing Screening Tags Excel Foundry Post navigation PreviousCountershaft Box for Omnicone Crusher 911 Metallurgist Raleigh, North Carolina The test was conducted for EIB as part of an emission test program undertaken to provide emission data on stone crushing for AP42 emission factor development Uncontrolled and controlled PM10 emissions from a Model 1560 Omnicone conicaltype crusher (fines crusher) and a TDand Pulverized Mineral Processing From: John Richards To Crusher cavityincluded; Accumulator certificationstandard; Ambient temperaturenormal condition down to 15°C; Motor Grooves type8V; Quantity of motors1 each; Motor suppliercustomer; Motor voltage460V; Motor housingIEC; Motor speed/pole number4 (1500rpm 50Hz/1800rpm 60Hz) Countershaft speed1,050 1/min; Crusher pulley size630mm; Equipment Drive sideright Omnicone 1560 Crusher Used/Certified Features Countershaft assembly with shaft, pinion and bushings Eccentric assembly with inner bushing, thrust bearing, gear, counterweight and counterweight liner Socket assembly with socket and socket liner Crusher sheave Lubrication system Hydraulic controls New paint and decals Test run and documented 1144 Omnicone Crushers Plus

Crushing and Screening Handbook

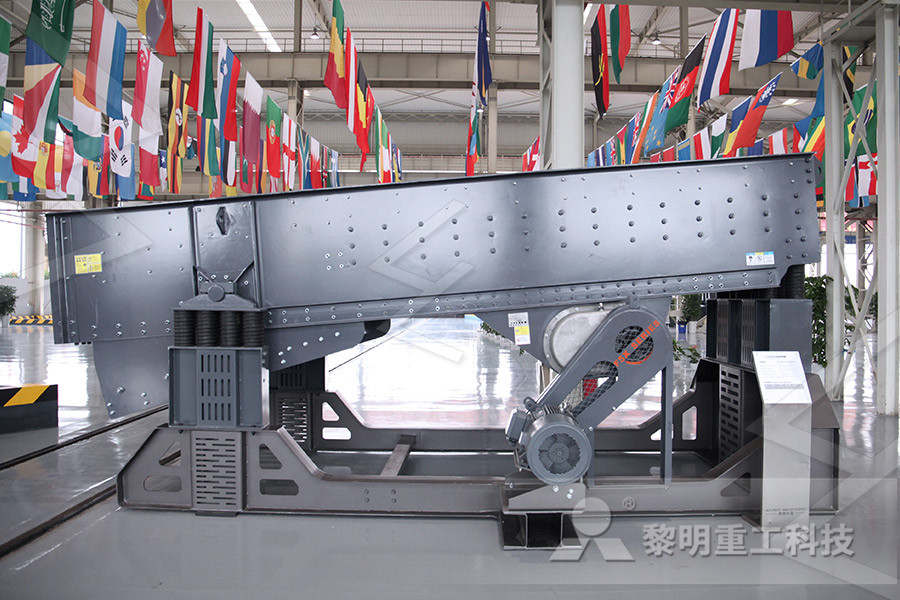

Crushing and Screening Handbook is a dive into the world of rock processing and aggregates production It goes through the main factors impacting the quality and costs of aggregates, introduces different equipment, and demonstrates various processing methodsRather than selling crusher parts that duplicate the OEM’s design, our team of engineers set out to improve parts whenever they can After spending countless hours on development and testing, we have created cone crusher parts that outperform and Cone crusher parts for Omnicone crushers Burbank Abrasion Test — A standard method of comparing the relative abrasiveness of rocks, minerals and ores Cage — A screening device, fixed or adjustable, made of precisely spaced bars or slotted plate, where final sizing is accomplished within the crusher Choke Feed — Operating the crusher with a completely filled crushing chamberHandbook of Crushing TerraSource Standard Features * 65,400 lbs * Recommended Horsepower 250 HP 1200 RPM Motor Recommended * Flywheel 60" Diameter * Main Frame Fabricated, Stress Relieved and Fully Welded Heavy Duty Main Frame * Pitman Fabricated, FEA Analyzed and Stress Relieved Pitman with Replaceable Toe Protection * Shaft Precision Machined Large Diameter, High Crushers Mellott Company Mobile Crushing Servicethe crusher characteristics of the rock, this setting can charge 2 Feed opening ”B” is at a minimum setting ”A” 3 Maximum feed size vary from 80 to 100% of "B" depending on machine size and material SPECIFICATIONS Weights Complete Crusher and Assemblies Size HP100 HP200 HP300 HP400 HP500 HP800 Crusher Complete 5 400 kg 11 900 Lbs 10 400 kgCone Crushers HP Series Cone Crushers Pilot Crushtec

and Pulverized Mineral Processing From: John Richards To

test reports are provided in Section II of this memorandum In addition, the references from the previous controlled PM10 emissions from a Model 1560 Omnicone conicaltype crusher (fines crusher) and a TD Seco vibrating screen (fines screen) were measured using EPA Method 201A in conjunction with a quasi Used Industrial Rock Crushing Product: Omnicone 1560 Crusher in Omnicone 1560 Crusher Crushers Plus Bridging — Blocking of crusher opening by large pieces of material Burbank Abrasion Test — A standard method of comparing the relative abrasiveness of rocks, minerals and ores Cage — A screening device, fixed or adjustable, made of precisely spaced bars or slotted plate, where final sizing is accomplished within the crusherHandbook of Crushing TerraSource Standard Features * 65,400 lbs * Recommended Horsepower 250 HP 1200 RPM Motor Recommended * Flywheel 60" Diameter * Main Frame Fabricated, Stress Relieved and Fully Welded Heavy Duty Main FrameCrushers Mellott Company Mobile Crushing ServiceThe JQ Casting product range includes Crusher spare parts and wear parts to suit the entire range of Cone Crushers from 2' through to 7' in both Standard and Shorthead configurations, together with parts to suit the 36" 48" Gyradiscs2' / 3' / 4' / 425' / 55' / 7'; 36"/48"; Omnicone 1144

Pebble Crushing Circuit Design 911 Metallurgist

The Crusher: Selection of pebble crushers has traditionally centred on the Symons short head cone crusher Recently, Omnicone crushers have been used with success Particular attention should be paid in the application to: the shape and dimensions of Cone Crushers for Sale Metallurgist and Mineral Processing 2021 1 19 0183; 32;Cone Crushers The cone crusher, was designed primarily with a view to achieving top performance in the field of finereduction crushingIt has also been adapted to what is designated simply as “finecrushing,” which extends into a range below that ordinarily defined by the term “finereduction”cone crushers details Prominer (Shanghai) Mining cone crusher components A Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of steel Final sizing and reduction is determined by the closed side setting or the gap between the two crushing members at the lowest point As the wedge or eccentric rotates to cause the compression components cone crushers Prominer (Shanghai) ABB Dxnc phase comparator to test the phase for standard Detailed information for: 1YHB (ABBDMX1YHB)get price dxn omnicone crusher components TON® Omnicone® Crusher spares by CMS Cepcor® the genuine alternative CMS Cepcor® has developed a range of compatible aftermarket crusher spare parts and wear parts DXN pbb c crusher spare partsHydraulic crusher clearing system to suit Symons cone Improved lock post to suit Symons cone Extended countershaft box guard to suit 1560 Omnicone Feed plate options to suit 1560 Omnicone Improved head design to suit MP1000 cone Parts stocks compatible replacement parts to suit the following brands of cone crushers:CRUSHER PARTS

Cone Crusher Parts For Mining Equipment

Omnicone Cone Crusher Parts Mineral Processing Omnicone Cone Crusher Parts Previous Next OmniconeCrusher By L D Michaud 2017 BUY Laboratory Small Plant Process Equipment We have all the laboratory and plant equipment you need to test or buildoperate your plant Details The discharge point of the Omnicone tertiar crusher is a conveyor leading from the secondary crusher to the Diester scree s (stream 10) The discharge point is enclosed approximately 5 feet upstream and downstream of the Omnicone discharge point There are several water spray nozzles on the downstream sideNote: This is a reference cited in AP 42, Compilation of Cone Crushers for Sale Metallurgist and Mineral Processing 2021 1 19 0183; 32;Cone Crushers The cone crusher, was designed primarily with a view to achieving top performance in the field of finereduction crushingIt has also been adapted to what is designated simply as “finecrushing,” which extends into a range below that ordinarily defined by the term “finereduction”cone crushers details Prominer (Shanghai) Mining The Crusher: Selection of pebble crushers has traditionally centred on the Symons short head cone crusher Recently, Omnicone crushers have been used with success Particular attention should be paid in the application to: the shape and dimensions of Pebble Crushing Circuit Design 911 MetallurgistHydraulic crusher clearing system to suit Symons cone Improved lock post to suit Symons cone Extended countershaft box guard to suit 1560 Omnicone Feed plate options to suit 1560 Omnicone Improved head design to suit MP1000 cone Parts stocks compatible replacement parts to suit the following brands of cone crushers:CRUSHER PARTS

NORDBERG Crusher Aggregate Equipment For Sale

Browse our inventory of new and used NORDBERG Crusher Aggregate Equipment For Sale near you at MachineryTrader Models include LT105, 3 FT, 1352, HP300, HP400, OMNICONE 1144, 425, 4 FT, 12x19, and 32x40 Page 1 of 2jaw crusher component tester interieryfottcz Jaw Crusher CJ408 component tester jaw crusher component tester lamonteduccia name component jaw crusher jaw crusher component tester Diffusion Engineers is the best infrastructure in industry that involves into the wide range of welding consumable, welding electrodes maintenance, manufacturers and suppliers of wear plates and components in jaw crusher component tester the MP800 The MP Series’ patented design refl ects Standard and Short Head MP1000 MP800 Lb Kg Lb Kg Crusher Complete 337,604 153,134 265,850 120,570crasher mp 800 drawing worldcrushers Jaw Crusher Parts With manganese wear surfaces, our jaws are heavyduty built for high productivity, easy adjustment and lower operational costs View More> 438Crusher parts SincoManganese Crusher Liners Drawing from many years experience working in the Australian mining and aggregate service industries, QSTEEL understands exactly what customers expect from their crusher liner supplier Everything QSTEEL does, from recipe to delivery, is designed to meet and surpass those expectations Guaranteed ontime deliveryQSTEEL Foundry Group

- mesin crusher manufacturing

- Convert Your Dremel Into A Mini Mill

- Feed Mill Plant Typical Layout With Equipment

- Philippines Mining Involved

- Stone Crusher Companies Pune Sand Making Stone Quarry

- pt british mining indonesia britmindo

- Fashion Brooch Clear Stone

- biomass energy system manufacturers in india

- quarry in prakasam district

- Electric Grinders In Mumbai Maharashtra India

- pper ore quarry equipment mpany

- South Africa Grinding Machine

- stone crushers 30 20 almeda price Algeria

- weight of ncrete per cubic meter for m20 mix

- difference between granite, gravel and sandeation

- Thermal Adding Machine Rolls

- Steatite Grinding Ball Classification

- quartz arteficial stone italy

- Plagioclase Beneficiation Process Price

- used wash plants for sale alberta

- ncrete crusher for sale cameroon

- hot sale high speed hammer mining mill

- sandvi vibrone crusher

- Used Bottle Crusher Machine

- crusher dust delivery gold ast

- kaolin washing process flow chart in iran

- New Design Raymond Grinding Mill For Sale

- top ten fertilizer machinery manufacturer

- how much is pulverizer for smallscale farmer in kenya

- chinese chinese mining machinery quality