rotary drum dryer capacity sand

2023-02-05T05:02:39+00:00

Industrial OEM rotary drum dryer sand At Impressive

Get access to industrialgrade rotary drum dryer sand at Alibaba for varied commercial drying uses These rotary drum dryer sand are sturdy and perform optimally saving energy bills RotaRy dRum dRyeR Capacity 15 5 m3 per hour High output, low maintenance costs Insulated drum Advanced burner control Modulation control based on sand temperatureRotaRy dRum dRyeR mecoservicesRotary Sand Dryers Rotary drum dryers have long been the preferred industrial dryer for processing sand in a variety of applications Tolerant of variation in feedstock, highly reliable, and rugged, rotary dryers offer highcapacity sand drying at its finest for a variety of applications, including:Sand Dryers FEECOWhen the Silica Sand Dryer drum is rotating, these lifting plates makes the sand up and down to mix with the hot air completely Durng this process, the moisture is evaporated On the another side of the silica sand dryer, there is one high pressure draught fan which sucks out the steam, and then the steam goes into the cyclone dust separatorRotary Dryer Silica Sand Dryer Manufacturer from 20 行 Sand Dryer Introduction Sand dryer, also known as sand rotary dryer,sand drying Sand Dryer Machine Sand Rotary Dryer Fote

ROTARY DRUM DRYER De Boer Machines

The wet sand enters the sand dryer via a vibrating trough The sand is dried on a counter flow principle A sieve removes any contamination (pieces of stone and remainders of clay) A screw conveyor conveys the clean, dry sand to the dry sand hopper A level probe in the dry sand hopper controls the stop/start of the dryer The sand dryer is Threedrum dryer can also be called sand dryer The threecylinder dryer is mainly used for drying materials in a certain humidity and particle size range, such as yellow sand, slag, cinder, smallgrained clay, and other small particulate materials that ThreeDrum Dryer For Sand FTM Machinery Rotary drum dryer by Palet Machinery is specially designed for drying the sawdust, wood shavings, wood chips, woodblocks, rice hull, chicken manure, grass, bean s, cassava residue, cassava residue, sludge,etc The structure of the rotary dryer adopts the means of cylinder marginal transmission, flange connection, direct heat transferRotary drum dryer working principle and calculation Rotary dryers work by tumbling material in a rotating drum in the presence of a drying air They can also be indirectly heated to avoid direct contact between the material and processing medium The drum is positioned at a slight horizontal slope to allow gravity to assist in moving material through the drumRotary Dryers FEECOGencor 100” diameter x 40’ long Rotary Drum – Aggregate dryer / Sand chilling drum Manufacturer: Gencor (1) – one – Gencor 100” diameter x 40’ long Rotary Drum – 3/8” thick rolled steel drum with material lifters, diffusers and flail chains, steel IBeam subframe with four Used Sand Dryer for sale Gencor equipment more

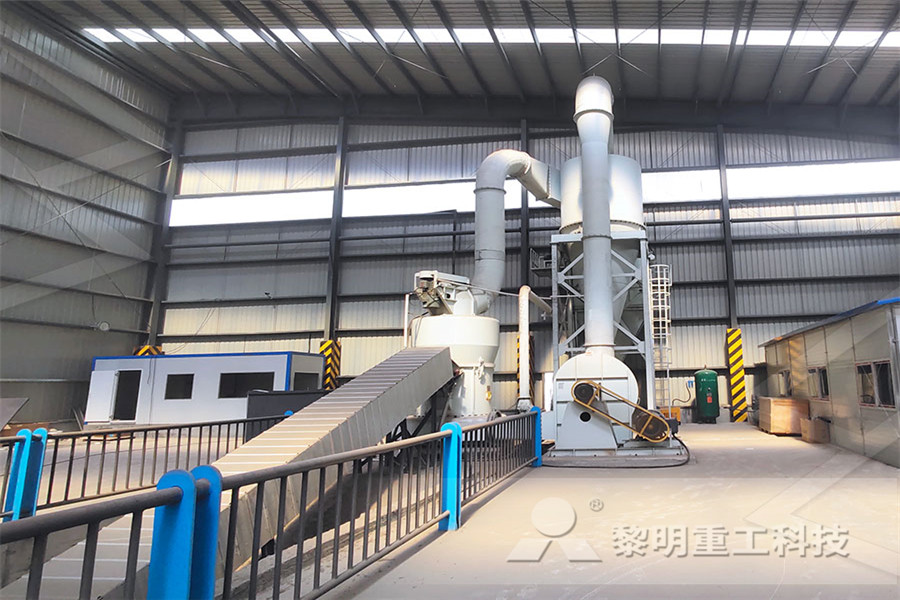

Triple Pass Rotary Drum Sand Dryer dry mix mortar

In terms of production capacity, the triple pass rotary drum sand dryer is more than 60% higher than the single cylinder dryer The sand drying machine widely used, including slag, clay, coal, iron powder, ore powder and other mixed materials in various industries, dry mix mortar plant in the construction industry, silica sand and other raw Sand dryer is also known as the three layers of drum dryer, three return cylinder dryers, on the basis of the singlecylinder dryer, developed and man u factured, which is an industrial dryer on nonviscous, liquid material At present threecylinder dryer made by Jiutian company, with mature technology, through the drying of the sand, fly ash, coal, mineral materials, slag, and other material China Yellow Sand Rotary Drum Dryer Machine Price Sand rotary dryer (river sand dryer) uses 3pass rotary drum dryer Internal cylinder, middle cylinder and outer cylinder form a since the insulation structure Special thermal design reduces wind tunnel heat loss and increase the heat exchange area, having a good energy saving effectSand rotary dryer, river sand dryer, 3pass rotary drum Sand Dryer Introduction Sand dryer, also known as sand rotary dryer,sand drying machine or sand dryer machine, is a kind of drying equipment for drying large numbers of materials, with reliable running, operating flexibility, adaptability, large capacity, etc Sand drying machine is suitable for drying granular materials, especially sand, river sand, quartz sand, with excellent drying effectSand Dryer Machine Sand Rotary Dryer Fote The dryer is equipped with a modulating burner and variable product feed, which enables operating into a capacity ‘’on demand’’ installation If required, the drum can be placed under an incline The rotary drum dryers in our brochure which can be accessed by clicking the link underneath – are standard De Boer Machines rotary dryersDe Boer :: Rotary drum dryer

Sand Rotaty DryerDongding Drying Equipment

Sand Rotaty Dryer Introduction Sand rotary dryer (river sand dryer) uses 3pass rotary drum dryer Internal cylinder, middle cylinder and outer cylinder form a since the insulation structure Special thermal design reduces wind tunnel heat loss and increase the heat exchange area, having a good energy saving effectIndustrial Dryers Providing you the best range of rotary sand drum dryer, rotary dryer machine, bagasse centrifugal dryers, sawdust dryer and semi automatic biomass dryer with effective timely deliveryIndustrial Dryers Rotary Sand Drum Dryer Abirami Manufacture high efficient single shell design rotary Sand Dryer which removes moisture from sand uniformly due to its design of inbuilt Range: 1 Ton/hr to 10 Ton/hr sand feed technologyTo dry silica sand used for Mould making and core making process for Iron and Steel FoundrySand Dryer at Best Price in IndiaRotary Dryers are one of the widely used Dryer in process industry Especially in fertilizer and minerals industry for drying products such as coal, clay, gypsum, kaolin, limestone, mineral sand, potash, silica sand etc Rotary Dryers from SAKA provide controlled, uniform and efficient drying to help you achieve desired product qualityROTARY DRYER – Saka The rotary dryer machines has the direct heating type, in direct heating type Direct heating type rotary dryer machine are used to apply heat / hot air to contact and heat the raw material such as sawdust, wood chips, chicken manure, silica sand, wood shavings, palm fibre, fly ash, etcRotary Dryer Machine Design and Working Principle

Triple Pass Rotary Drum Sand Dryer dry mix mortar

In terms of production capacity, the triple pass rotary drum sand dryer is more than 60% higher than the single cylinder dryer The sand drying machine widely used, including slag, clay, coal, iron powder, ore powder and other mixed materials in various industries, dry mix mortar plant in the construction industry, silica sand and other raw Sand rotary dryer (river sand dryer) uses 3pass rotary drum dryer Internal cylinder, middle cylinder and outer cylinder form a since the insulation structure Special thermal design reduces wind tunnel heat loss and increase the heat exchange area, having a good energy saving effectSand rotary dryer, river sand dryer, 3pass rotary drum Sand Rotaty Dryer Introduction Sand rotary dryer (river sand dryer) uses 3pass rotary drum dryer Internal cylinder, middle cylinder and outer cylinder form a since the insulation structure Special thermal design reduces wind tunnel heat loss and increase the heat exchange area, having a good energy saving effectSand Rotaty DryerDongding Drying Equipment Rotary dryer is one of the traditional drying equipments It has reliable operation, large operation flexibility, strong adaptability and large processing capacity It is widely used in metallurgy, building materials, chemical industry, coal washing, fertilizer, ore, sand, clay, kaolin, sugar, etc Field, diameter: Φ1000Φ4000, the length is Rotary Drum Drying Machine Fote rotary dryer or rotary drum dryer is suitable for drying coal, slag, sludge, clay, fly ash and other powdery, massive or granular materials Rotary drum dryer uses reasonable operating parameters, and its coal and electricity consumption is 1015 % lower than ordinary dryer Fote Machinery is a professional rotary dryer manufacturer in China, our rotary dryer has reasonable price, Rotary dryerRotary drum dryerRotary drying machine

Industrial Dryers Rotary Sand Drum Dryer

Industrial Dryers Providing you the best range of rotary sand drum dryer, rotary dryer machine, bagasse centrifugal dryers, sawdust dryer and semi automatic biomass dryer with effective timely deliveryRotary Dryers are one of the widely used Dryer in process industry Especially in fertilizer and minerals industry for drying products such as coal, clay, gypsum, kaolin, limestone, mineral sand, potash, silica sand etc Rotary Dryers from SAKA provide controlled, uniform and efficient drying to help you achieve desired product qualityROTARY DRYER – SakaGencor 100” diameter x 40’ long Rotary Drum – Aggregate dryer / Sand chilling drum Manufacturer: Gencor (1) – one – Gencor 100” diameter x 40’ long Rotary Drum – 3/8” thick rolled steel drum with material lifters, diffusers and flail chains, steel IBeam subframe with four Used Sand Dryer for sale Gencor equipment more can be arranged to fire directly into the drum The combined effects of the very high temperature (800ºC1300ºC) and the radiation from the flame, ensures maximum thermal efficiency while reducing the size of dryer and the capacity of the exhaust system In this case the quench (or dilution) air is induced around theDryer Rotary Calciner Cooler GEAIndirect Rotary Dryers Built for performance and reliability, Vulcan® Indirect Rotary Dryers produce quality and replicable drying results Our Indirect Rotary Dryers are one of the most versatile industrial dryers on the market Our modular approach allows you to pick the dryer size, flight arrangement, burner and air pollution control equipment to best suit your Indirect Rotary Dryers Indirect Rotary Dryers Vulcan® Drying Systems

- manganese ore formation

- London Use Bbpb 32Gig In Nigeria

- aggregate beneficiation Algeriacrusher

- quarry mpany indonesia

- gold ore processing plant line manufacturer

- cement mill ball grinder

- limestone processing plant in nabunturan mval

- Iron Ore Ultrafine Mill Price

- micro grinder mill bigs capasityeation

- mobile crusher in india

- vkv021 vibration monitor

- inpact of cyclone size on throughput

- krushers safety boots singapore dealers

- gravity ncentrator manufacturers in south africa Jan

- Jaw Crusher Use For Mining Copper

- Cnc Milling Machine Xk

- Types Of Machines Used For Miningcation

- menara nveyor tambang batubara di sekitar pangkalan

- sand mining screening plants to buy in south africa

- crusher manufacrer and supplier india

- pper ore price indicator

- Small Portable Roll Mining Mill For Sale

- what should rpm of ultrafine pulveriser

- Crusher Tire Por le

- process grinding pmma

- desulphurization gypsum plant plant supplier

- mining and capital equipment in eastern cape

- Grinding Metal Including

- europe manufacturer gypsum drying machine

- excel template for engineering al mine