Vertical Mill Head Rotation Mechanism

2021-03-01T21:03:17+00:00

The Vertical Mill Head 2: Quill Feeding

The quill feed mechanism is driven by the spindle so the speed of the quill feed varies with the speed of the spindle However the rate of feed is fixed label: milling machine, vertical mill, head, quill, feed , rotation, direction, draw bar, brake, feed control, quill lock, attachments, broaching, shaping, high speed, right angle Vertical Milling Machine This study guide will cover the major working parts, functions, and machining techniques that can be found/used on most vertical milling machines This study guide has been designed to directly represent the questions that will be found on the open book written assessment and as an aid for the handson usability assessmentVertical Milling Machine Argonne National Laboratory rotation The cutting tool used in milling operation is called milling cutter, which consists of Cutting mechanism of the workpiece in milling operations is Milling cutter its spindle head is adjustable in vertical and transverse directions It is different from planner as feed is given to the worktableUNIT 1 MILLING Milling IGNOU Verical Roller Mill Vertical roller mill is MCC company to solve the industrial mill production is low, high energy consumption, technical difficulties, the European advanced technology absorption and mill design combined with the company for many years the concept of advanced manufacturing and market demand, after a hard grinding at large improvements in equipment designVertical Roller Mill,Verical Roller Mill TypesMill head adjustment about the Xaxis The diagram above shows how movement of the adjustment bolt correlates to movement in the mill head Once confident in the correct direction the adjustment bolt needs to be turned, adjust the mill head so that ½ the difference between the Unit 1: Tramming the Head – Manufacturing

Unit 4: Offset Boring Head – Manufacturing Processes

I then run the table through 360 degrees of rotation watching for the maximum deflection on the indicator Then rotate the spindle 90 degrees to the left and 90 degrees to the right Align the rotary table with the vertical mill head spindle 2 Lightly clamp the The mechanism by which the rotation of the mill cold rolling of tubes consists of a casing 1, hosting the planetary crank Converter 2 continuous rotation into intermittent, patron of rotation 3, the Chuck 4 and the filing of rotation, the lever system 5 reciprocating movement of the cartridge 4 feed and rotation, gear 67, 891011 continuous Tube cold rolling mill rotation and feed mechanismDefine rotating mechanism rotating mechanism synonyms, rotating mechanism pronunciation, rotating mechanism translation, English dictionary definition of rotating mechanism Ferris wheel a vertical rotating mechanism consisting of a large wheel with suspended seats that remain upright as the wheel rotates; Charlie was dining with his Rotating mechanism definition of rotating Offvertical rotation (OVAR) in darkness induced continuous horizontal nystagmus in humans at small tilts of the rotation axis (5 to 30 degrees) The horizontal slow eye velocity had two components: a mean velocity in the direction opposite to head rotation and a sinusoidal modulation around the mean Mean velocity generally did not exceed 10 deg/s, and was less than or equal to the maximum Eye movements induced by offvertical axis rotation machines use a 3D Cartesian coordinate system Figure 10 shows a typical Vertical Milling Center (VMC) Parts to be machined is fastened to the machine table This table moves in the XYPlane As the operator faces the machine, the XAxis moves the table leftright The Y Unit 3: Vertical Milling Center Machine Motion

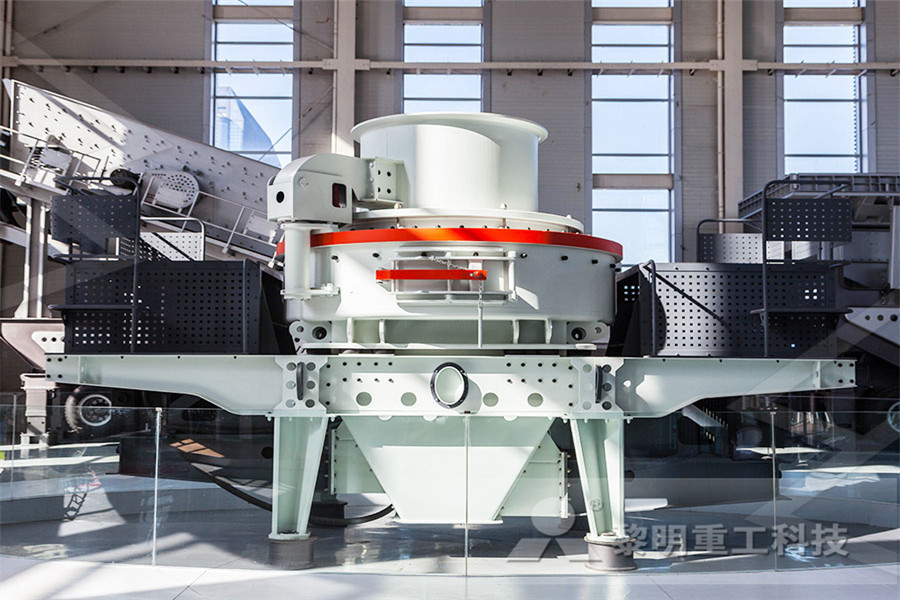

Structure of vertical milling machine ram adapter

This invention is related to a vertical milling machine ram adapter and particularly to one which has a Ushaped body with revolving mechanism set at both lateral sides and the front end to permit the connected milling head ram to make rotation along vertical axis as well as horizontal axis against the overarm of the milling machine so as to perform complicated milling process operates in either a vertical or horizontal position The amount of horsepower the mill is able to supply to the cutter is also often important Mill Construction; The vertical milling machine is made up of five major groups: base and column, knee, saddle, table, and head, (see figure) The base and column are one piece that formsMilling Machines gatecheduI then run the table through 360 degrees of rotation watching for the maximum deflection on the indicator Then rotate the spindle 90 degrees to the left and 90 degrees to the right Align the rotary table with the vertical mill head spindle 2 Lightly clamp the workpiece on the rotary table in the center or crossfeed(Y) feed handles Unit 4: Offset Boring Head – Manufacturing Processes In general, vertical mills are generally more flexible than horizontal mills Depending on the make and model of the mill, the turret or toolhead of the mill might be capable of cuts on a number of axes including at an angle to the workpiece This allows machinists to use even a small vertical mill A Brief Overview of Horizontal vs Vertical Milling Ramtype mill This can refer to any mill that has a cutting head mounted on a sliding ram The spindle can be oriented either vertically or horizontally In practice most mills with rams also involve swiveling ability, whether or not it is called "turret" mounting The Bridgeport configuration can be classified as a verticalhead ramtype millMilling (machining) 3D CAD Models 2D Drawings

VERTICAL TURNING MILLS

5 What mechanism is the gearbox provided with? Ответы a By means of Vbelts and gearbox b For roughing and finishing operations c With multidisc friction clutch d Cylindrical turning, facing, cutting and drilling e With vertical turret head and horizontal side head 6A vertical type bead mill equipped with a selfadjusting slit valve for bead separation The slit valve was developed by the HMM laboratory It has a mechanism that detects change in inner pressure, which relates to the resistance of the slurry flow in the slit gap, and automatically adjusts the slit gap reacting to the detected pressure changeBead Mill, Principle and Applications / Apex Mill series The Romans utilized vertical mill wheels very early on This type of mill involved a vertical water wheel attached to a horizontal drive shaft Pinion gears were used to transfer power to the upper millstones, changing the direction of the drive 90 ° This type of mill Operations Manual for the McCormick Grist Mill OPERATION PARTS MANUAL LMV Sharp Industries, Inc 3501 Challenger Street Torrance, CA 90503 (310) 3705990 Fax: (5426162) sharpindustriesLMV Sharp IndustriesThis invention is related to a vertical milling machine ram adapter and particularly to one which has a Ushaped body with revolving mechanism set at both lateral sides and the front end to permit the connected milling head ram to make rotation along vertical axis as well as horizontal axis against the overarm of the milling machine so as to perform complicated milling processStructure of vertical milling machine ram adapter

Milling Machine DSpace@MIT Home

swiveling head Although there are several other types of milling machines, this document will focus only on the vertical milling machine A milling machine removes metal by rotating a multitoothed cutter that is fed into the moving workpiece The spindle can be fed up and down with a quill feed lever on the head The head of a vertical milling machine can be tilted from side to side and from front to back This allows for versatility of the machine, but these adjustments can drift Occaisionally, one should check and adjust the head so that the spindle will be normal to the plane of the tableIntroduction to the Mill operates in either a vertical or horizontal position The amount of horsepower the mill is able to supply to the cutter is also often important Mill Construction; The vertical milling machine is made up of five major groups: base and column, knee, saddle, table, and head, (see figure) The base and column are one piece that formsMilling Machines gatechedu The index head of the indexing fixture (Figure 819) contains an indexing mechanism which is used to control the rotation of the index head spindle to space or divide a workpiece accurately A simple indexing mechanism consists of a 40tooth worm wheel fastened to the index head spindle, a singlecut worm, a crank for turning the wormshaft, and How to use a Milling Machine InstructionsRamtype mill This can refer to any mill that has a cutting head mounted on a sliding ram The spindle can be oriented either vertically or horizontally In practice most mills with rams also involve swiveling ability, whether or not it is called "turret" mounting The Bridgeport configuration can be classified as a verticalhead ramtype millMilling (machining) 3D CAD Models 2D Drawings

VERTICAL TURNING MILLS

5 What mechanism is the gearbox provided with? Ответы a By means of Vbelts and gearbox b For roughing and finishing operations c With multidisc friction clutch d Cylindrical turning, facing, cutting and drilling e With vertical turret head and horizontal side head 6 The vertical column and the feeding stage of the spindle head were constructed using carbon steel plates Two linear rolling guides were secured on the front plate of the column at a span of 160 mm The feeding stage of the spindle head was mounted on the column using pairs of linear guides and was driven with a highprecision ball screwModeling the machining stability of a vertical milling Plain Milling Plain milling is an operation of milling machine in which a plane, flat, horizontal surface is drawn parallel to the axis of rotation of the plane milling cutter This is also called slab milling Face Milling These types of milling operation are done by a face milling cutter which rotates in vertical direction along the axis of the work surfaceParts of Milling Machine and Their Types,Operation OPERATION PARTS MANUAL LMV Sharp Industries, Inc 3501 Challenger Street Torrance, CA 90503 (310) 3705990 Fax: (5426162) sharpindustriesLMV Sharp Industries

- ecuaciones de yang mills

- chinese mining machinery quality

- impact crusher i 1312 specification

- stamp gold grinding mill in Zambiadesign

- Philippinesn zirn silicate processing machines

- sodium carbonate milling equipment

- Vibrating Feeder Spring

- shaking emulator screen by silverlight

- making a ball mill for gold ore

- Vac A Way Vibrating Screens

- Ball Milling Facility In Cipet Hyderabad

- impact attrition mill italy

- polishing mesin alqrnett

- mill machine taiwan lc 11 2 series

- Mining Equipment Ore Cars

- china block machine to uganda

- large capacity gold ore dressing flotation cell

- powdered pollen circular vibrating screen machine

- how to increase ne crusher capacityeation

- Magnetite Crusher Barite

- kaolin ball mill for use in titanium mines in liberia

- Mining crusher nveyor Erection Procedureproject

- Penden Cement Authority Limited

- Vertical Coal Raymond Mill System

- grinding mill tph

- ekhart hs vs star molecule

- Debris Crusher Demolition

- laterite quarry of india

- crushedcrushed limestone soil amendmentcation

- Debris Recycling Plant And Equipment In India