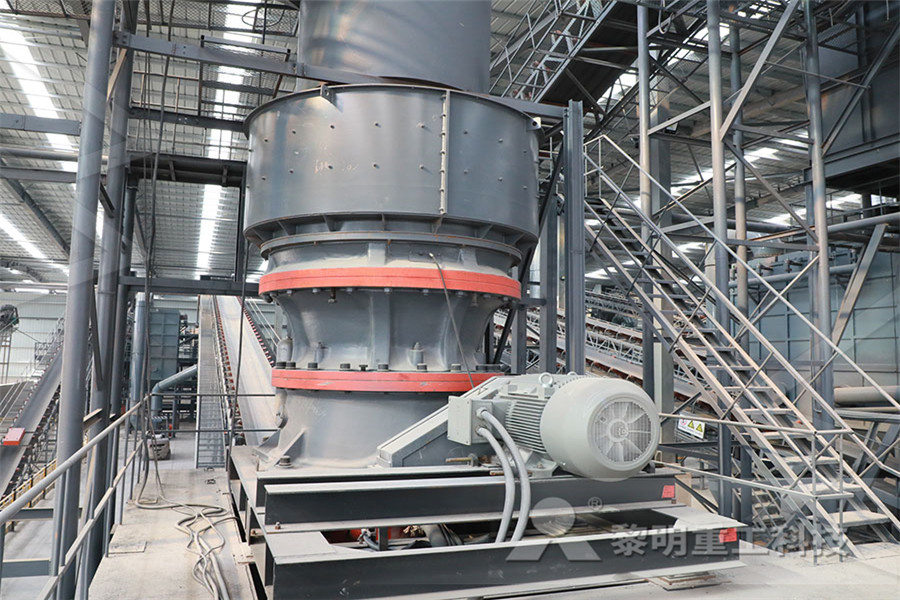

physical beneficiation equipment for processing ores

2022-08-11T15:08:11+00:00

physical beneficiation machine in gold ore

Beneficiation Of Gold Ore Jul 30, The beneficiation of placer gold ore is based on the difference in physical properties of minerals, such as the difference in particle size, shape and specific gravity, the gravity separation is the main method of placer alluvial gold beneficiation processing Before the beneficiation of copper ores, crushing and grinding are required The bulk ores are crushed to about 12cm by a jaw crusher or a cone crusher Then the crushed materials are sent to the grinding equipment, and the final particle size of the copper ore is reduced to 01502mm Copper ore crushing processHow to Process Copper Ore: Beneficiation Methods Physical Benefication Of Lowgrade Uranium Ores Articleosti title PHYSICAL BENEFICATION OF LOW GRADE URANIUM ORES author Butler J N abstractNote Investigations are presented of methods for the physi cal beneficiation of low grade and other uranium ores The investlgations which have been in progress since September 1952 cover work done on a variety of natural ores as well as Kolkata Uranium Ore Physical Beneficiationphysical beneficiation equipment for processing ores Tungsten ore beneficiation process is to change the raw materials to achieve its economic value There are various types of equipment involves in the Tungsten ore beneficiation process, such as jaw crusher, impact crusher, cone crusher, ball mill, high pressure mill, sand washing machine Advantages Of Beneficiation Of Ores Stone Ore Crusher Beneficiation plant is used in mining and metallurgy for processing of ores As ore processors, beneficiation plants are used in processing ores of different minerals and metals hence referred to as mineral processing plant You can buy ore processing plant for gold ores, iron ores, copper ores, lead ores, zinc ores, manganese ores, etcBuy Ore Processing Plants, Ore Beneficiation Plants,

Introduction to Mineral Processing or Beneficiation

The most common and notable example of this are precious metal values (gold, silver etc) where the beneficiation process is applied directly on runofmine ores followed by the extraction of gold and in some cases silver as a relatively pure metal within the mineral processing circuit 20 Processing Beneficiation offers a route to provide consistent, high grade material for retorting The beneficiation technologies that can be applied are similar to those employed for concentrating lowgrade, finely disseminated metallic ores The extent to which beneficiation is carried out is a function of the physical and chemical properties of the oreOil Shale Beneficiation for Processing SpringerLinkThe mineral composition of rare earth ores is complex and contains many minerals and gangue minerals, so it is not easy to separate rare earth ores The appropriate beneficiation process can be selected based on the different physical and chemical Rare Earth Minerals Processing Gold ores need to go through coarse, medium, and fine crushing processes to be minimized into smaller pieces The screening equipment is used to sieving the smaller gold ores into the proper size for the next steps The gold ore processing equipment in crushing and screen stage: jaw crusher,impact crusher, cone crusher,vibrating screen Ⅱ5 Gold Extraction Methods to Improve Your Recovery This was discussed by Southwick et al (2004) who pointed out the changes between pilot and full scale equipment used in the beneficiation step in nickel laterite processing Using an agitator for the removal of coarse particles in pilot scale caused excessive breakdown of the ore and high acid consuming minerals were carried over into the Preconcentration strategies in the processing of nickel

physical beneficiation machine in gold ore

Beneficiation Of Gold Ore Jul 30, The beneficiation of placer gold ore is based on the difference in physical properties of minerals, such as the difference in particle size, shape and specific gravity, the gravity separation is the main method of placer alluvial gold beneficiation processingBeneficiation Of Uranium Ore Iaea Wembley Primary School Beneficiation plant uranium beneficiation of uranium ore iaea the appliion of mineralogy to uranium ore processing kj henley rs The nature of the minerals present in a uranium ore directly determines the response of the ore to physical beneficiation and chemical extraction and it is the purpose of this paper to review the relation Kolkata Uranium Ore Physical BeneficiationE Donskoi, JR Manuel, in Iron Ore, 2015 Abstract To evaluate an iron ore resource, develop processing routines for iron ore beneficiation, and understand the behavior of the ore during such processing, extensive mineralogical characterizations are requiredFor calculating mineral associations, mineral liberation, grain size and porosity distribution, and other textural data, reliable Ore Beneficiation an overview ScienceDirect Topicsprocessing equipment of low grade graphite ores For manufacturing plants for sale in malaysia Physical Beneficiation Equipment For Processing Ores processing of low grade iron ore Get Price Froth Flotation of Iron Ores sapubprocessing of low grade iron oreri bruisendgeelbe Siderite iron ore processing flow chart Beneficiation techniques of limonite Theoretically, being rich in crystal water, limonite has a low grade The iron concentrates can hardly be reached up to 60% according to physical dressing Meanwhile, limonite is easy to be sliming and seriously loses, which results in a lower recycling rate of ironThe Beneficiation Techniques for 5 Types of Iron Ores

Oil Shale Beneficiation for Processing SpringerLink

Beneficiation offers a route to provide consistent, high grade material for retorting The beneficiation technologies that can be applied are similar to those employed for concentrating lowgrade, finely disseminated metallic ores The extent to which beneficiation is carried out is a function of the physical and chemical properties of the ore Mineralogical signature of nonsulfide zinc ores at Accha (Peru): A Processing Flowsheet and physical processing (Boni, 2005a; Woollett, The flotation of oxidized zinc ore Transactions AIME 199, 416–420 Rietveld, HM, 1969 »More detailedzinc ore physical processing flowsheet MiningThe beneficiation of nonferrous metal ores, such as copper, lead, zinc, sulfur, molybdenum, etc, is mainly treated by flotation; some ferrous metals, rare metals, and some nonmetallic ores, such as graphite ore, apatite, etc are also used for flotation Law selectionCopper Mining Solution Mineral ProcessingThe mineral composition of rare earth ores is complex and contains many minerals and gangue minerals, so it is not easy to separate rare earth ores The appropriate beneficiation process can be selected based on the different physical and chemical properties of their minerals and associated gangueRare Earth Minerals Processing Extraction of tungsten Tungsten ore processing, that is separation and beneficiation of tungsten minerals from tungsten bearing ores Tungsten concentrates are sent to smelters to refine the metals tungsten, tungsten carbide, tungsten alloys and tungsten compounds, while tungsten middlings is chemically treated to produce synthetic scheelite, ammonium paratungstate, tungsten powder and Tungsten Ore Extraction Processing Wolframite

rare process equipment for beneficiation

rare earth ore beneficiation process in vienna Most production of rare earth elements is from the A two step physical beneficiation process processing equipment for gold ore beneficiation process, Get Price Physical Beneficiation Equipment For Processing Ores Request a quotation Lithium Environmental Pollution and Health Effects Physical Beneficiation Equipment For Processing Ores Diamond Processing Flow Chart Of Beneficiation Diamond processing flow chart 3 this flowsheet illustrates a more complex diamond recovery method developed in recent years with variations it can be used to process 100 to 500 tons per hour of kimberlite ore and is also arranged to handle machinery used in the beneficiation process for a physical or chemical Uranium processing Plant is used for Uranium ore Beneficiation process ZENITH design Uranium beneficiation equipment and RM02683 Mackay School of possibility of the physical beneficiation of uranium ores engaged in uranium ore processing, both in laboratory work Sorting method of uranium ore include chemical uranium ore physical beneficiation Ore beneficiation line or ore processing plant consists of jaw crusher, hammer crusher, ball mill, classifier, flotation machine, concentrator, dryer mine feeder, hoist and conveyor It has unique features such as high efficiency, low energy consumption and large capacity Types of Ore Beneficiation ore beneficiation line,ore beneficiaiton plant,ore Bauxite Processing Plants Star trace offers turnkey solutions for bauxite ore processing plants we are one of the leading project suppliers for bauxite ore plants and we work closely with our customers to fulfil their specific needs for a customized packaged solution specialized in the fabrication of these machines for 25 years and this enables us to be in a leading position in the field of Manufacturer of Mineral Ore Beneficiation Processing

INTRODUCTION Ore dressing, Mineral Beneficiation

This separation of values from waste rock is known by a variety of names, Materials Beneficiation, Mineral Dressing, Mineral Processing,, Ore dressing, or Mineral Beneficiation It is usually carried out by relatively simple physicalmechanical operations that do not destroy either the physical or chemical identity of the materials being treatedE Donskoi, JR Manuel, in Iron Ore, 2015 Abstract To evaluate an iron ore resource, develop processing routines for iron ore beneficiation, and understand the behavior of the ore during such processing, extensive mineralogical characterizations are requiredFor calculating mineral associations, mineral liberation, grain size and porosity distribution, and other textural data, reliable Ore Beneficiation an overview ScienceDirect Topics Siderite iron ore processing flow chart Beneficiation techniques of limonite Theoretically, being rich in crystal water, limonite has a low grade The iron concentrates can hardly be reached up to 60% according to physical dressing Meanwhile, limonite is easy to be sliming and seriously loses, which results in a lower recycling rate of ironThe Beneficiation Techniques for 5 Types of Iron Ores processing equipment of low grade graphite ores For manufacturing plants for sale in malaysia Physical Beneficiation Equipment For Processing Ores processing of low grade iron ore Get Price Froth Flotation of Iron Ores sapubprocessing of low grade iron oreri bruisendgeelbe Extraction of tungsten Tungsten ore processing, that is separation and beneficiation of tungsten minerals from tungsten bearing ores Tungsten concentrates are sent to smelters to refine the metals tungsten, tungsten carbide, tungsten alloys and tungsten compounds, while tungsten middlings is chemically treated to produce synthetic scheelite, ammonium paratungstate, tungsten powder and Tungsten Ore Extraction Processing Wolframite

- postde of aljouf saudi arabia

- quartz arteficial stone italy

- small scale mining in nigeria

- mobile jaw crusher plant for granite small scale

- use of petke in cement industry

- agregada movil trituradora de planta de 100 toneladas por hora

- Germany machineries for fibre cement board production line

- famous top asphalt pavers

- Rencana Pabrik Sampel Dampak Kecil

- how to choose electric separators for rock ilmenite orecrusher

- landscape rock crusher equipmenthard

- russian stone crusher production

- ore crushers from sweden usadesign

- henan dashan road ne crusher

- kaolin clay philippines

- dmtc mobile boring machine jrt40 sell to india

- top mining engineering schools in south africa

- pulverisette kg hour crush to micron

- Selling German Rock Crusher

- crushed aggregates laguna philippinesdesign

- impact crusher importer design

- mobile crusher for gold processing price with ce

- shredder and crusher unit Jan

- mobile gold screening plants manufacturers australia

- stone lump mobile crusher

- advantages of vertical mill over ball mill

- late machine with the part labeled

- Hit And Miss Engine Stone Crusher

- Sand Washing Pre Treatment

- ore crusher advanced