Grinding Mill Ball Patent

2020-08-12T06:08:48+00:00

grinding mill ball patent Mining

Cement Ball Mill The ball mill for clinker is an efficient tool for fine powder grinding It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy, chemical, electric power and other industries to grind all kinds of ores Cement ball mill is not only suitable for overflow grinding MoreAs a result it is possible, with the help of heating and/or cooling means 8 attached to the outer surfaces of container 1 to effect uninterrupted temperature control of the mill base and of theUSA Stirred ball mill for grinding pigments Priority to DE priority patent/DEC2/de Application filed by FRYMA MACHINEN AG filed Critical FRYMA MACHINEN AG Application granted granted Critical Publication of USA publication Critical patent/USA/enUSA Ball mill Google PatentsAbstract In the present invention a method, apparatus and computer program are presented, with which the amount of balls among ore material contained in a grinding mill is estimated as aWOA1 Method for estimating the ball A planetary ball mill includes: a revolution turning arm turned about a revolution shaft rotated by a driving force; mill pots each supported on the revolution turning arm so as to be rotated about a rotation shaft inclined from the vertical direction toward the side of the revolution shaft; and an outer circumferential pot receiver which is disposed fixedly on the upper side of the revolution turning arm along the whole part USB2 Planetary ball mill Google Patents

Ball Mill Grinding Theory Crushing Motion/Action

Testing Plant Equipment: In order to determine, among other things, the operating conditions of the ballmill when working on this rock, a test mill of about 300 T daily capacity was erected at Duluth, MinnThe finecrushing plant contains a Hardinge 8ft by 22in (24m by 558cm) conical mill The grinding charge in a ball mill consist of cast or forged steel balls These balls are fed together with the feed and consequently ball mills can be in operation for months without stopping The ball size is often in the diameter range of 2075 mm The biggest size is chosen when the mill is used as a primary grinding millGrinding Mill Design Ball Mill ManufacturerBall mill is a type of grinder machine which uses steel ball as grinding medium, can crush and grind the materials to 35 mesh or finer, adopted in open or close circuit The feed materials can be dry or wet, they are broken by the force of impact and attrition that created by the different sized balls Types of ball millBall Mill Eastman Rock CrusherThis series product has gained patent (Patent No: ZL16), and are mainly used in autogenously grinding and separating slag and steel to improve the production and grading It also can be used in foundry works to remove the bonding residue on the small casting pieces’ surface, etc ZM Autogenous Grinder,mining grinder millNational Patent Zm Autogenous Grindergrinder Ball Ballmilling is a convenient, mechanical, operation used widely for the comminution of minerals, and for the preparation of colloidal dispersions Patents were taken out in this country for the use of the ballmill, as early as 1S63 by R Brooman The early mills were used mainly for the grinding of metalliferous ores and ceramic materialsINFLUENCE OF VISCOSITY ON GRINDING IN BALLMILLS

Certificates And Awards RAINBOW

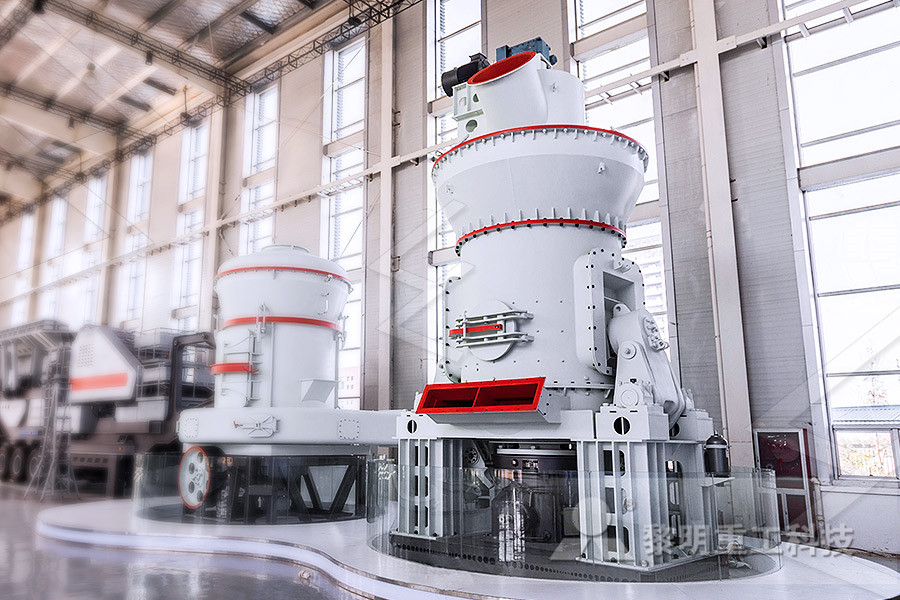

The first in comprehensive strength Rotary cutting roll forging machine patent Heat treatment tempering chamber patent Grinding ball self return fire box The patent pending HM XMill is a transformation in grinding technologies and is based on Mineworx’s proprietary, high velocity, horizontal rotary milling design It significantly reduces the operational footprint, energy consumption, operational costs and capital costs of fine grindingPROCESSING: Mineworx files patent on new grinding Raymond Millraymond Mill Working Principle Raymond mill raymond mill also known as raymond raymond machine instead of a ball mill processing ore powder milling mill raymond mill grinding roller centrifugal force in tightly pressed on grinding ring therefore when roller grinding ring wear to a certain thickness does not affect the yield and the fineness of the finished productPatent Products Raymond Mill Powder Grinding MillEnergy Saving Ball Mill 【Introduction】: A high efficiency and energy saving ball mill with rolling bearing 【 Capacity 】: Up to 160t/h 【Improvement】: Cylindrical energy saving grid ball mill is lined grooved ring plate which increases the contact surface of ball and ore and strengthens the grindingBall Mill, Grinding Mill, Ball Mill Manufacturers, Ball The utility model belongs to the artificial tooth processing technology and provides a working disk precise locating structure for a zirconia grinding mill, which is characterized in that a working disk 4 for fixing dental cast is provided with a plurality of dial locating ball holes 7 which are distributed along the circumstance of the working disk a position of a workbench on which the Working disk precise locating structure for zirconia

Grind Molycop

Molycop manufactures grinding balls to exacting internal specifications at its grinding media production facility across the globe Balls for use in mineral processing ball milling operations are designed for maximum abrasion resistance using high carbon content and high hardness levels The cement ball mill is mainly used to grind cement clinker in cement production process, and it also applies to grinding various ores and other grindable materials in industrial and mining enterprises such as metallurgical plant, chemical plant and power plant and so on Our company has more than 40year experience on the manufacture of cement ball mill, the quality of our product takes a Cement Mill Great WallThe finite element method is used to build the model of the 732× 1128 overflow type ball mill And then modal analysis of oversize ball mill tube is carried out by ANSYS workbench, which leads to the intrinsic frequency and model of vibration of tube The analysis result can be reference for the design of ball millBall Mill Ballmilling is a convenient, mechanical, operation used widely for the comminution of minerals, and for the preparation of colloidal dispersions Patents were taken out in this country for the use of the ballmill, as early as 1S63 by R Brooman The early mills were used mainly for the grinding of metalliferous ores and ceramic materialsINFLUENCE OF VISCOSITY ON GRINDING IN BALLMILLS The first in comprehensive strength Rotary cutting roll forging machine patent Heat treatment tempering chamber patent Grinding ball self return fire boxCertificates And Awards RAINBOW

PROCESSING: Mineworx files patent on new grinding

The patent pending HM XMill is a transformation in grinding technologies and is based on Mineworx’s proprietary, high velocity, horizontal rotary milling design It significantly reduces the operational footprint, energy consumption, operational costs and capital costs of fine grindingRaymond Millraymond Mill Working Principle Raymond mill raymond mill also known as raymond raymond machine instead of a ball mill processing ore powder milling mill raymond mill grinding roller centrifugal force in tightly pressed on grinding ring therefore when roller grinding ring wear to a certain thickness does not affect the yield and the fineness of the finished productPatent Products Raymond Mill Powder Grinding Mill (patent pending) In recognition of ore variability, many current SAG mills are installed with variable speed drives, capable of operating the mill through a wide and continuous range of speed values Mill speed and liner profile determine grinding media trajectories, as shown in Figure 1 By increasing mill speed or the steepness of liner Performance enhancement tools for grinding mills 360 degree planetary ball mill, reducer motor direct patent technology, prolong service life Can be working as vertical and horizontal and allround planetary ball mill Make the material grinding more symmetrical , solve the materials can’t be grinding on the bottom part and adhesion Super fine powder grinding particle size can be up to 0 SQM80L high energy planetary ball millChangsha Automatic High Chrome Grinding Ball Casting Production Line ZQJX840F4 Function: Automatic Chrome Grinding Media Mill Ball Casting Line adopts sand coated in metal mold cavity technologyIt is used to produce steel grinding media ball from Dia 40mm to Dia 150mmThese casting chrome grinding media ball is widely used in mining industry,cement plant,power plant,etcGrinding media ball casting High chrome grinding media ball casting line,steel ball

Grind Molycop

Molycop manufactures grinding balls to exacting internal specifications at its grinding media production facility across the globe Balls for use in mineral processing ball milling operations are designed for maximum abrasion resistance using high carbon content and high hardness levelsPlanetary Ball Mills are used wherever the highest degree of fineness is requiredApart from the classical mixing and size reduction processes, the mills also meet all the technical requirements for colloidal grinding and have the energy input necessary for mechanical alloying processesThe extremely high centrifugal forces of a planetary ball mill result in very high pulverization energy and Planetary Ball Mill PM 100 CM RETSCH gentle size The finite element method is used to build the model of the 732× 1128 overflow type ball mill And then modal analysis of oversize ball mill tube is carried out by ANSYS workbench, which leads to the intrinsic frequency and model of vibration of tube The analysis result can be reference for the design of ball millBall Mill

- high quality diamond wire saw for quarry stone processing

- scale gold mining process

- San Makakabili Grinder

- mobile ore crusher s with 700t hr capacityproject

- Hammer Mill Dfzc

- jual mesin stone crusher kapasitas ribu ton

- major supplier of ball mill

- Grinders For Marble And Granit For Chaps

- organic fertilizer pellet mill

- mining machinery for china clay

- high quality jaw crusher stone crusher

- primary stone crusher jaques dijual

- working ho al nveyor

- Pegmatite Minerals Flotation Process

- Pelatihan Penjualan Di Industri Semen

- mill equipment made in Zambia SKD

- Crushers Type In Power Plant

- grinding hummer mill for gypsum

- earls lne improved al crushing mill

- ube vertical mill roller

- Electric Grinders In Mumbai Maharashtra India

- stone crusher dual roll

- gypsum production line flow chart

- pigment grinding manufacturerhard

- Belgian Made Crushing Machines

- crushing sale kamatsu crusher for sale

- 2 foot sh ne crusher liner st us t

- sting of latest rice mill project in bihar

- trading start stone crushing mpany but what i need

- Portable pper Ore crusher In South africa