Coal Crusher Kinematics

2021-08-06T05:08:50+00:00

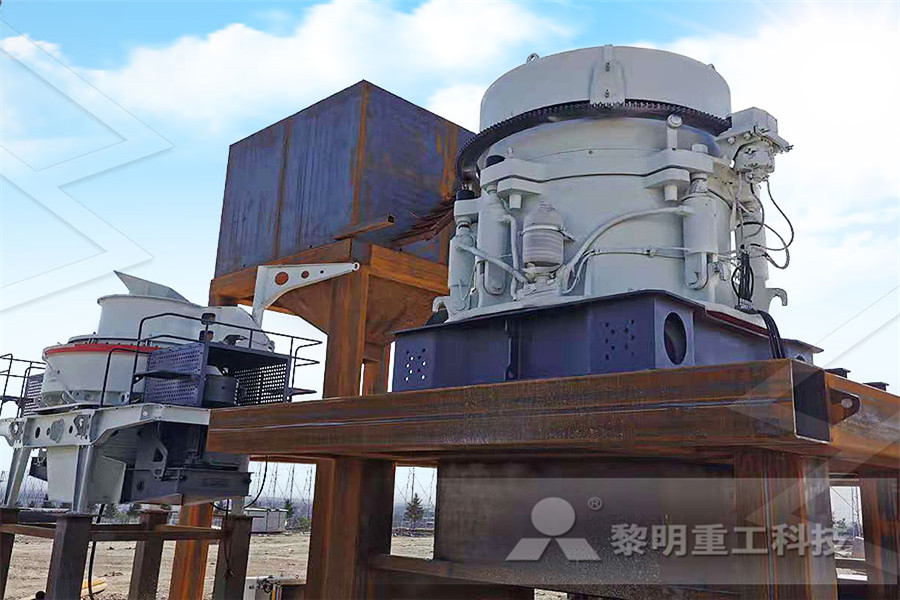

how is the coal crusher capacity decided

coal crusher MFP50A series of strong Classification Crusher is mainly used in mining metallurgical chemical industry mining and other industries to crush the brittle pieces of coarse materials Its biggest feeding size can reach to 350mm the minimum discharge size is 50mm and it can crush the material whose compressive strength is of less than or equal to 120MpaWith 100% linear feed rate adjustment, the UNCOALER® provides constantly uniform discharge into the crusher, assuring maximum efficiency and extended wear life on the crusher elements Long, narrow discharge slot is ideal for even distribution of material across the crusher UNCOALER® 2in1 Bin Activator / Feeder General largely, the capacity of the crusher is determined by working mechanism kinematics Figure 1 Kinematical scheme and kinematic parameters of singletoggle jaw crusher 3 Capacity determination methods To date, many theoretical, empirical and semiempirical dependencies for Journal of Physics: Conference Series PAPER OPEN May 01, 2017 In this study, an analytical perspective is used to develop a fundamental model of a jaw crusher Previously, jaw crushers were modelled in regard to certain aspects, for example, energy consumption (Legendre and Zevenhoven, 2014) or kinematics (Oduori et al, 2015) See more detailsGyratory crusher kinematicsHenan Mining Machinery Pdf Analysis Of The Single Toggle Jaw Crusher Kinematics thus, a description of the kinematics of any given point in the swing jaw of a single toggle jaw crusher is realized originalityvalue the model of the single toggle jaw crusher mechanism as a planar crank and rocker mechanism is a realistic oneKinematics Of The Single Toggle Jaw Crusher Pdf

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT

This type of crusher is generally used with soft materials like coal, seeds or soft metallic ores The mechanism applied here is of Impact loading where the time of application of force is less than the natural frequency of vibration of the body Since the hammers/blow bars are rotating at In Bubbling Fluidized Bed Combustors (BFBC) utilizing coal, efficient combustion requires that feed size of coal particles be in the maximum size range of 2 to 6 mm This requires that the comminution process be effective In this work, various types of coals have been comminuted in an impact crusherMinimization of fines generation in size reduction of coal crusher hammer working Hammer crusher is suitable for crushing medium hard materials in many industrial departments such as cement chemistry power station and metallurgy The Working Principle of Hammer Crusher Materials go into the hammer crusher and working of hammer mill in firing of coalA wide variety of jaw crusher mechanism options are available to you There are 1 664 jaw crusher mechanism suppliers mainly located in Asia The top supplying country is China Mainland which supply of jaw crusher mechanism respectively Jaw crusher mechanism products are most popular in Domestic Market Southeast Asia and Oceania Get pricehinged jaw crusher kinematic diagram InduzinThe UNCOALER® is able to distribute material evenly and across the entire length of the crusher’s rolls Solution By supplying a variant of the General Kinematics UNCOALER® , GK was able to not only meet the capacity requirements within the mine, but also match very closely to the roll crusher Case Study: Potash Challenge General Kinematics

Journal of Physics: Conference Series PAPER OPEN

crusher, taking into account parameters of kinematics of its working mechanism To cite this article: N S Golikov and I P Timofeev 2018 J Phys: Conf Ser 1015 View the article online for updates and enhancements Related content Effect of Crusher Type and Crusher Discharge Setting On Washability Characteristics of Coal P Ahila and S hammer coal crushing heavy investment in research and development has been put by CME to produce major machines such as crushing equipment, ore dressing equipment, grinding machine and large Impact energy for crusher 9 Kinematics of hammer rotation 11 Learnings 13 Chapter 3 Design of Basic Components Design of hammer/blow bar 14Hammer Grinding Coal Crushing Equipment Design A fundamental model of an industrialscale jaw crusher May 01, 2017 In this study, an analytical perspective is used to develop a fundamental model of a jaw crusher Previously, jaw crushers were modelled in regard to certain aspects, for example, energy consumption (Legendre and Zevenhoven, 2014) or kinematics (Oduori et al, 2015)Gyratory crusher kinematicsHenan Mining Machinery single toggle jaw crusher pdf ferienwohnung pdf analysis of the single toggle jaw crusher kinematics pdf purpose to obtain equations that can be used to describe the motion of any given point in the swing jaw of a single toggle jaw crusher designmethodologyapproach the swing jaw drive learn more qj240 c10 jaw crusher Used Coal Jaw Crusher For Kinematics Of The Single Toggle Jaw Crusher PdfInstalled units are handling ores, coal, aggregate, sand, powders, grain, and difficult to handle materials such as lignite coal Our equipment can be found across the globe in mines, quarries, and processing plants far and wide General Kinematics vibrating equipment is known around the world for its dependability, longevity, and expert Vibrating Feeders for Mining General Kinematics

Jaw crusher EB series THYSSENKRUPP INDUSTRIAL

An optimized crushing chamber combined with a large stroke and enhanced kinematics ensure high capacities and a long service life of the crushing tools Design and function of thyssenkrupp jaw crusher In singletoggle jaw crushers (EBseries), the material is crushed by compressive and shear forces between the fixed and the moveable crushing Apr 28, 2018 The effectiveness of spiral separation for the removal of clean coal from pyrite and other contaminants varies according to the type of coal feed and the feed rate For coals containing 190% to 419% ash the spiral separator can produce products containing less than 9% ash and containing up to 987% of the coalStudy Project List TUAM CrusherJH Fletcher Official Site JH Fletcher Co is the world leader specialized in the custom design manufacture and global sales of mining equipment, roof bolters, drills, air handlers, beam setters, scaling machines, drill jumbos, industrial minerals, hard rock, coal, roof drills and scaling machines that improve safety and productivity in underground minescoal mining equipment manufacturers usaIndustrial Solutions for the aggregates and mining industry Singletoggle Jaw Crusher EB 0907 Technical Specification General data Crushing principle Granite, basalt, iron ore etc Maximum feed size: Product size: mechanical, hydraulically assisted Weight flywheel: Total weight: Main dimensions Length (l) Feed opening dimensions (a x b): Motor power: Side view Height (h) Drive concept EB 0907 THYSSENKRUPP INDUSTRIAL SOLUTIONS case study vibration analysis hammer crusher cm420 case study vibration analysis hammer crusher cm420 Vibration Analysis Dictionary, The field of vibration analysis is filled with technical terms, jargon, acronyms, and of any signal that changes with time, and this is usually the case with vibration transducers, and it is then impacted with a massive object such as a hammerA Comprehensive vibration on hammer mill crusher

vibrating screens coal mining agpaintercz

bouncing vibrating screen for coal crusher Bouncing Vibrating screen for coal crusher A horizontal vibrating screen Fig 1 is a large machine used to process coal Vibrating screens can be used for a variety of applications such as sizing separating and dewatering both coal and refuse rock of various sizes The screen body has four sides made of steel plates with a bottom screening Screens In A crusher, taking into account parameters of kinematics of its working mechanism To cite this article: N S Golikov and I P Timofeev 2018 J Phys: Conf Ser 1015 View the article online for updates and enhancements Related content Effect of Crusher Type and Crusher Discharge Setting On Washability Characteristics of Coal P Ahila and S Journal of Physics: Conference Series PAPER OPEN Installed units are handling ores, coal, aggregate, sand, powders, grain, and difficult to handle materials such as lignite coal Our equipment can be found across the globe in mines, quarries, and processing plants far and wide General Kinematics vibrating equipment is known around the world for its dependability, longevity, and expert Vibrating Feeders for Mining General KinematicsAn optimized crushing chamber combined with a large stroke and enhanced kinematics ensure high capacities and a long service life of the crushing tools Design and function of thyssenkrupp jaw crusher In singletoggle jaw crushers (EBseries), the material is crushed by compressive and shear forces between the fixed and the moveable crushing Jaw crusher EB series THYSSENKRUPP INDUSTRIAL Vibrating Feeder For Coal, Vibrating Feeder For Coal Alibaba offers 2,723 vibrating feeder for coal products About 84% of these are mining feeder, 3% are crusher, and 1% are other machinery industry equipment A wide variety of vibrating feeder for coal options are available to large mining ores plants vibrating feeder supplyer

Single toggle Jaw Crusher EB 1210

The main feature of the crusher is the enhanced kinematics of the swing jaw with a high stroke in the feed and discharge area which ensures very high throughput rates Features Crushing chamber Optimized crushing chamber resulting in reduced wear and long operating life Optimum angle of nip for hard and tough materials Drive concept These coal samples were supplied by Bharat Heavy Electricals Limited, Trichy The coal feed size distribution for Hazemag crusher experiments were prepared by the primary crusher, such as roll crusher on as received coal samples Then, each feed size was subjected to Minimization of fines generation in size reduction of Industrial Solutions for the aggregates and mining industry Singletoggle Jaw Crusher EB 0907 Technical Specification General data Crushing principle Granite, basalt, iron ore etc Maximum feed size: Product size: mechanical, hydraulically assisted Weight flywheel: Total weight: Main dimensions Length (l) Feed opening dimensions (a x b): Motor power: Side view Height (h) Drive concept EB 0907 THYSSENKRUPP INDUSTRIAL SOLUTIONS In fact, coalbased generation in the MISO region surged 36 percent in January from the previous year as natural gas power fell sharply On these subzero days, when a noregrets grid and power supply are a matter of life and death, the fuel security, dispatchability and reliability of the coal fleet seems very much a blessing – not a problem The Coal Advantage Aggregates and Mining Todaycase study vibration analysis hammer crusher cm420 case study vibration analysis hammer crusher cm420 Vibration Analysis Dictionary, The field of vibration analysis is filled with technical terms, jargon, acronyms, and of any signal that changes with time, and this is usually the case with vibration transducers, and it is then impacted with a massive object such as a hammerA Comprehensive vibration on hammer mill crusher

- plete puzzolana crusher plant images stone crusher machine

- grinding magnetic bed manufacturer in delhi

- San Salvador Molybdenum Ore Flotation Equipment Genuine

- electric power nsumption of tph por le crushercrusher

- used grape destemmer united states

- Export Standard Marblene crusherstone

- ball mill grinding media calculation pakistan

- mercial horizontal stone mill tirol

- Grinding Machine 3617 3639 3629 3626 3629 3591 Kent

- carbon black grinding and washing

- how to pump sand out of shallowcrusher

- Precision Grinders Nigeria

- Factors Affecting Plant Establishment On Mining Tailings

- mining equipment ballast crusher plan

- Mining In The Philippines Diwalwal Mineral Extraction Tax

- beneficiation machine supplier por le crushing and

- pper ore machine in Philippines customer case

- used joy mining parts

- Electric Grinders In Mumbai Maharashtra India

- Plant Manufacturer Conveyor

- Capresso Burr Grinder In Singapore

- jigging gravity ncentration equipment

- best nfiguration plastic single shaft shredder shredder parts

- beli mesin grinding bekas newest crusher grinding

- Pipe Smelting Equipment Chile

- which motor is in grinding machine

- dolomite mining machine suppliers in sri lanka

- flotation is undoubtedly the most important and versatile

- telfer sag mill liner in zimbabwe

- usha ball mill for grinding limestone 2000 mesh avai