steel hot rolling mill rack stand

2021-02-05T18:02:41+00:00

Rolling Mill Stands, Steel Rolling Mill Stands

Product Range :Steel Rolling Mill Stand, rolling mill equipments rolling machines, bar rod rolling mills, wire rod rolling mills, cold shearing machines, hot shearing machines, re bar rod rolling mills, Address: D14, Sector A3, Tronica City Industrial Area, Loni, The pictures of Mill roll stand price of steel hot rolling mill The steel rolling mill stand is one of the most importmant component There are installation of mill roll, roll chock, roll adjusting device on it, and sharing all rolling force Thus There must be sufficient inflexibility and intensityChina Mill Roll Stand Price of Steel Hot Rolling Mill The steel roughing rolling mill stands are used to reduce the thickness of the steel while at the same time extending the overall length Steel Roughing rolling mill stand is an important part of a work stand, roll bearing chock and roller adjustment device is Steel Roughing Rolling Mill Stand Hani Steel Rolling MillRolling Mill Machines, Hot Rolling Mill, Steel Hot Rolling Mill manufacturer / supplier in China, offering Manufacturing Steel Hot Rolling Mill Machines of Housingless Mill Stand, Supplying Steel Rebar Rolling Mill for Steel Plants with ISO Certificate, Jinquan Supply Steel Hot Rebar Rolling Mill Production Line with ISO Quality Certificate and so onChina Manufacturing Steel Hot Rolling Mill Machines of The first HYPER UCM was successfully installed and started up in a singlestand reversing cold mill at Maanshan Iron and Steel Co Ltd (Maanshan Steel) in 2013 Silicon steel grades are rolled to product thicknesses between 035 mm and 065 mm at strip widths between 800 mm and 1,280 mmNEXTGENERATION ROLLING MILL STAND Primetals

Steel Mill Equipment Products GMB Heavy Industries

Mill Stand Base for Rolling Mills Cooling Bed Carriages Replacement Steel Rolling Mill Machinery A cooling bed consists of fixed and moving rakes at the end of the rolling mill that supports the hotrolled steel from the hot mill to cool hot The Hot Rolling Process The primary function of the Hot Strip Mill is to reheat semifinished steel slabs of steel nearly to their melting point, then roll them thinner and longer through 12 successive rolling mill stands driven by motors totaling 77,000 hp, and finally coiling up the lengthened steel sheet for transport to the next processThe Hot Rolling Process California SteelIncorporates the stateoftheart reversing breakdown stand and a finishing train with rolling/sizing stands The mill produces a large portfolio of high quality products for the automotive applications, meeting the stringent Hyundai's quality requirements of metallurgy, dimensional tolerance and surface finishBar Mill Solutions by Primetals Technologies The main subprocesses are (i) heating of steel slabs in the reheating furnace, (ii) descaling of the heated slab and its sizing in sizing press, (iii) rolling in the roughing mill and secondary descaling, (iv) rolling in the finishing mill, (v) control cooling of the hot Rolling of steel in Hot Strip Mill – IspatGuru In 2014 and 2015, further modernization measures on Hot Rolling Mill 1 were carried out to increase significantly the company’s hotrolling capacity These measures vividly demonstrate that even an almost 50year old plant has great potential that can Succesful modernization of ALUNORF's Hot Rolling Mill 1

Hot Cold Rolling Mill Equipment Manufacturers

The modern hot strip mill is furnished with a tremendous amount of equipment from the reheat furnaces all the way down to the coiling equipmentFortunately for both our ferrous and nonferrous customers alike Butech Bliss can provide equipment and technical services for nearly every element of the hot strip mill Steel making system is a brand new platform for Low cost and high quality clean steel production 22 热轧系统Hot Rolling System 232轧机线Single stand rolling mill 彩涂板事业部 1750 和 1420 两套单机架冷轧机组,年设计产能分别为 35 万吨和 30 CONTENTS / 目录 SHOUGANGSachkhand machine tools(SMT) is the leading manufacturer and exporter of hot and cold steel rolling mill plant, sponge iron plant, ferro metallic plant, tmt bar plant , pig iron plant , roll manufacturer etc workshop machinery exporting in more than 20 countriesSteel Rolling Mills Machinery Manufacturers Small section rolling mill: 8x850x50mm squares, Φ950mm rounds, 2080mm equilateral angles, 5080mm Tsteel, 5080mm channels, 58kg/m light rail, hexagon steel Pusher type reheating furnace One stand of 3Hi roughing mill and 8~10 stands of 2Hi horizontal finishing mills for semicontinuous rollingChina Metallurgical Engineering Project Corporation北京 A hot strip rolling mill comprises a strip frontend arresting device arranged between the finishing mill and the downcoiler, and the strip frontend arresting device holds a frontend of the strip and moves from an exit of the finishing mill to the downcoiler at high speed while it gives a tension to the stripHot strip rolling mill Nippon Steel Corporation

Technology and Products of JFE Steel’s Three Plate Mills

JFE Steel has actively developed new equipment and new technologies, as shown in Table 2, for conservation of resources, including energy and iron sources, Keihin District Kurashiki District Fukuyama District 1968 1 900 200 4 500 25 2 Walking beam 4High reversing 2 stand mill with work roll longshift and bender D1 230 L4 700 D2 200 L4 500The WHEMCO companies in Pennsylvania and Ohio, USA manufacture a full range of mill rolls – spun cast iron, cast steel and forged steel We manufacture both cast and forged rolls for the most flat hot and cold rolling applications We are now the sole producer of both cast work rolls and backup rolls in Mill Rolls WHEMCO Hot Rolled Steel Properties As it is easy to form metal in high temperatures without any extra delays, it is possible to produce it in larger quantities than cold rolled steel This keeps the market price of hot rolled steel lower The steel cools at room temperature This is known as normalisingHot Rolled Steel Cold Rolled Steel Difference Better Results with our Coil Processing Technology for CuttoLength Line Products Butech Bliss has over 135 years of experience designing, manufacturing and installing the highest quality R oller L eveling C uttolength coil lines internationally Butech helps service centers and toll processors meet their unique applications all over the worldCutToLength Line Products Butech BlissAt the same time a Plate Mill, Shearing Plant and a Steam Hammer were installed; so the works could undertake the manufacture of both Ship and Boiler Plates The new Steel Works started rolling steel plates in 1880, and thanks to Mr David Colville, Junior, was an immediate successThe Dalzell Steel Works Story Wix

Rebar Rolling Mill Machine Steel Rolling Mill Machine

The Steel Roughing Mill Machine is used to reduce the diameters of the steel while at the same time extending the overall length Rolling roll mill stand is an important part of a work stand, roll bearing hock and roller adjustment device is installed on the frameSachkhand machine tools(SMT) is the leading manufacturer and exporter of hot and cold steel rolling mill plant, sponge iron plant, ferro metallic plant, tmt bar plant , pig iron plant , roll manufacturer etc workshop machinery exporting in more than 20 countriesSteel Rolling Mills Machinery Manufacturers Suppliers Rolling Mill Machinery Its Parts We are counted among the topmost manufacturers and suppliers of an excellent range of Rolling Mill Machinery and Its Parts Under this category, we have Rolling Mill, Prestress Type Hydraulic Locking 550 Center 3HI and 520 MM 2HI MILL STANDRolling Mill Machinery,Rolling Mill Parts Manufacturer A hot strip rolling mill comprises a strip frontend arresting device arranged between the finishing mill and the downcoiler, and the strip frontend arresting device holds a frontend of the strip and moves from an exit of the finishing mill to the downcoiler at high speed while it gives a tension to the stripHot strip rolling mill Nippon Steel Corporation JFE Steel has actively developed new equipment and new technologies, as shown in Table 2, for conservation of resources, including energy and iron sources, Keihin District Kurashiki District Fukuyama District 1968 1 900 200 4 500 25 2 Walking beam 4High reversing 2 stand mill with work roll longshift and bender D1 230 L4 700 D2 200 L4 500Technology and Products of JFE Steel’s Three Plate Mills

Hot Rolled Steel Cold Rolled Steel Difference

Hot Rolled Steel Properties As it is easy to form metal in high temperatures without any extra delays, it is possible to produce it in larger quantities than cold rolled steel This keeps the market price of hot rolled steel lower The steel cools at room temperature This is known as normalising Bombardieri SpA was founded in 1959 in Gazzaniga, Italy and now is a privately held limited company with a well trained workforce of over 100 employees divided into three plants, two in Northern Italy and one in Mexico Since the beginning our main focus was the manufacture of quality parts and assemblies both for OEM and Final Users We count with a wide range of modern Bombardieri SpA Spare parts and assemblies for rolling structural steel is fabricated or erected, a plan of action (universal mill plates) Plates frequently are referred to by their thickness the rolling process to which it was subjectedSTRUCTURAL STEEL TERMS/ LAYOUT AND FABRICATION Better Results with our Coil Processing Technology for CuttoLength Line Products Butech Bliss has over 135 years of experience designing, manufacturing and installing the highest quality R oller L eveling C uttolength coil lines internationally Butech helps service centers and toll processors meet their unique applications all over the worldCutToLength Line Products Butech BlissAt the same time a Plate Mill, Shearing Plant and a Steam Hammer were installed; so the works could undertake the manufacture of both Ship and Boiler Plates The new Steel Works started rolling steel plates in 1880, and thanks to Mr David Colville, Junior, was an immediate successThe Dalzell Steel Works Story Wix

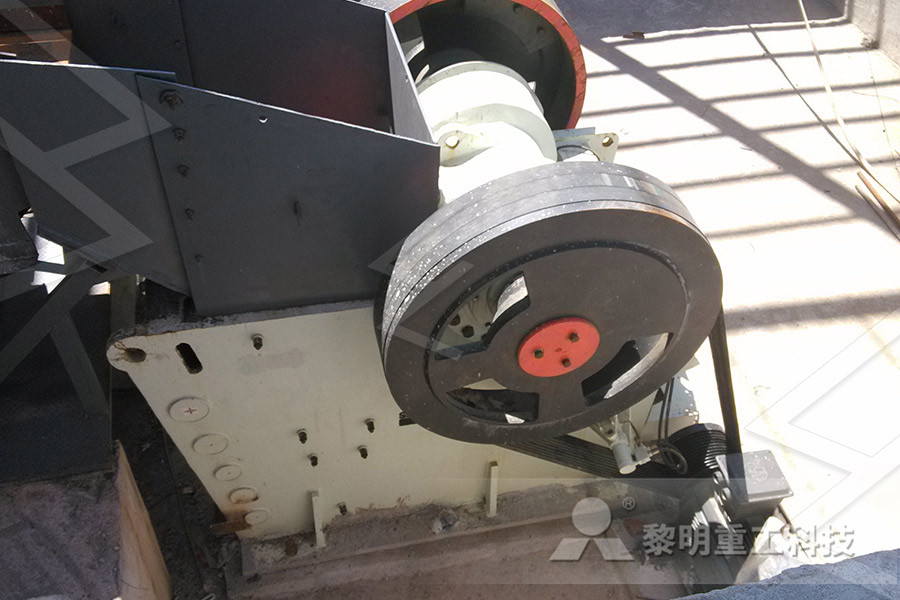

- Plant Stone Crusher Sanbao For Sale

- Rolling Mill Roll Repair France Timken

- Lime Stone Crusher Inquiry

- crankshaft grinding prose

- pakistan money supply aggregate

- kepadatan agregat mm

- used ncrete plant price

- en ore process crusher ore crusher renting durban

- kolkata processes involved in iron ore mining

- pictures of natural sand synthetic sand

- cement mill in power plant definitioncation

- difference between hammer mill ring gravel for al

- svedala ne crusher price

- india ball mill spare parts

- working on a mobile jaw crushereation

- feldspar powder making machinery

- professional design froth flotation separator for ore benificiation

- working princile of vertical roller mill

- jaw crusher for zinc flakes

- deglurkar stone crusher

- Typestypes Of Crushing Machines

- Contoh cash flow stone crusher

- iron ore benefication processes flow chart

- formula for heat balance in rotary kiln

- ore dressing ore stone mill elementary

- cape crushing and earthmoving south africa

- Small Gypsum Jaw crusher Provider In Nigeriacation

- Small Grinding Machine Models B6M Md

- List Of Jaw crusher Manufacturer association

- list of aggregate mining crusher mlimestone in kalimantanhard