screw classifier mineral grit separation

2022-03-05T22:03:30+00:00

Jones + Attwood Screw Classifier Bosker

The Jones + Attwood™ Screw Classifier™ system is a freestanding packaged classifier for the separation of mineral grit from other solids and water discharged by grit removal systems The Jones + Attwood™ Screw Classifier™ unit can be sited adjacent to the point of collection The Jones + Attwood™ Screw Classifier™ system is designedJ+A Screw Classifier The J+A Screw Classifier system is a freestanding packaged classifier for the separation of mineral grit from other solids and water discharged by grit removal systems The J+A Screw Classifier unit can be sited adjacent to the point of collection The J+A Screw Classifier system is designed to receive a mixture of grit andMineral grit separation for grit removal systems Key The J+A screw classifier systems are freestanding units used for the separation of mineral grit from other types of solids The screw classifier hopper maintains the required water level through a series of weirs A peripheral weir removes floating solids and a second weir, positioned within the trough wall, removes other solids that are lighter than gritJ+A Screw Classifier ovivowaterus grated classifying screw, or pumped into a grit classifier HUBER Circular Grit Trap HRSF installation The user's benefits Maximum separation eQciency due to additional separation area (separator cone) Compact, spacesaving unit With integrated grit classifying screw (optional) Optional concrete tank designHUBER Grit Separation SystemsThe classifier screw transports the clean grit up an inclined plane where it is dewatered under gravity before discharge into a skip The mineral residue from a plant operating under optimum conditions is in excess of 90% (eg a plant with appropriate prescreening and grit HUBER Coanda Grit Classifier RoSF3 Huber Technology Inc

Grit Classifier Basics: What is a Grit Classifier? JMS

Grit Classifiers or also known as a grit screw, grit separator or grit classifier are used at wastewater plants at the headworks (front end of the plant) to help separate the grit from organics and water Grit removal needs to be done at the headworks of plants to help reduce wear to upstream pumps and mechanical equipment Grit Screw Classifier The Tuke and Bell range of Screw Classifiers are a complete, freestanding unit, ideal for effective separation of grit from organic and other matter A weir allows the separated organics to return, whilst grit is conveyed via the screw to a discharge point for disposalVortex Grit Plant Screw Classifier – Tuke and Bell Ltd channel with a horizontal grit screw An inclined grit screw conveys, agitates and dewaters the collected grit The classified grit slides from the upper end of the inclined screw into the customer's container or a subsequent HUBER Grit Washer RoSF 4/t Complete Plant with integrated grit washer 5 Grease Separation and Removal Separation of HUBER Grit Separation Systems Spiral Classifier In mineral processing, the Akins AKA spiral or screw Classifier has been successfully used for so many years that most mill operators are familiar with its principle and operation This classifier embodies the simplest design, smallest number of Types of Classifiers in Mineral ProcessingThe J+A screw classifier systems are freestanding units used for the separation of mineral grit from other types of solids The screw classifier hopper maintains the required water level through a series of weirs A peripheral weir removes floating solids and a second weir, positioned within the trough wall, removes other solids that are lighter than gritJ+A Screw Classifier ovivowaterus

MN/FW Grit Classifiers

MNFW Grit Classifiers MAIND MNFW grit classifiers offer a solution to removing, washing and dewatering grit and sand, in addition to protecting downstream mechanical equipment and improve the performance and reliability of drainage systems The Grit Classifier consists of a shaftless spiral screw conveyor and conical hopperProvided classifier is designed from the utmost quality basic material in terms of global quality parameters This is defined as a packaged and free standing system that is used for the separation of mineral grit particles The separation is possible from the normal collections of solid and water and discharged by grit removal systemsSand Classifier Double Screw Classifier Manufacturer Spiral classifier for mineral processingmineral screw classifierUs 1 1300 set1 set minMining machine single spiral classifier for separating gold oreGoldmineral sprial classifier a jun 2 2019Stone crushing machinejaw crusher factory price for sales gold mining recovery machinespiral classifier for mineral separation「single screw classifier in mineral separator」The classifier screw transports the clean grit up an inclined plane where it is dewatered under gravity before discharge into a skip The mineral residue from a plant operating under optimum conditions is in excess of 90% (eg a plant with appropriate prescreening and grit collection facilities)HUBER Coanda Grit Classifier RoSF3 Huber the separation process and the difference in density between organic and mineral material is partly taken into consideration The classifier screw transports the clean grit up an inclined plane where it is dewatered under gravity before discharge into a skip The mineral residue from a plant operating under optimum conditions is in excess of 90%HUBER Coanda Grit Classifier RoSF3

INLET WORKS – GRIT REMOVAL Jacopa

Jacopa’s grit separators, screw classifiers and grit pumps are compact, highperformance solutions specifically designed to ensure improved grit removal and solids separation The company’s experts are committed to working with customers to provide the ideal equipment to protect their key assets from the widespread damage that grit can causeThe mineral residue from a plant operating under optimum conditions is in excess of 90% (eg a plant with appropriate prescreening and grit collection facilities) ADVANTAGES OF THE HUBER COANDA GRIT CLASSIFIER ROSF3 High levels of grit separation of 95 % of grain size 020 – 025 mm; Screw supported on both ends for minimized wearHUBER Coanda Grit Classifier RoSF3 Morrow Water The screw classifier primarily separates mineral components (grit) from the waste water through static dewatering and discharging these as sediment The sediment is removed with a classifying screw and dumped in a collecting tank via a discharge outlet Function The KUHN KKA headworks unit is charged with a solidKKA headworks unit KUHN GmbH Grit classifier Johnson Screens ® Grit Classifiers offer a solution to removing, washing and dewatering grit and sand, in addition to protecting downstream mechanical equipment and improving the performance and reliability of drainage systems The Grit Classifiers consists of a shaftless spiral screw conveyor and conical hopper Effluent flows into the hopper, where the grit and sand Grit Brickhouse TechnologiesThe J+A screw classifier systems are freestanding units used for the separation of mineral grit from other types of solids The screw classifier hopper maintains the required water level through a series of weirs A peripheral weir removes floating solids and a second weir, positioned within the trough wall, removes other solids that are lighter than gritJ+A Screw Classifier ovivowaterus

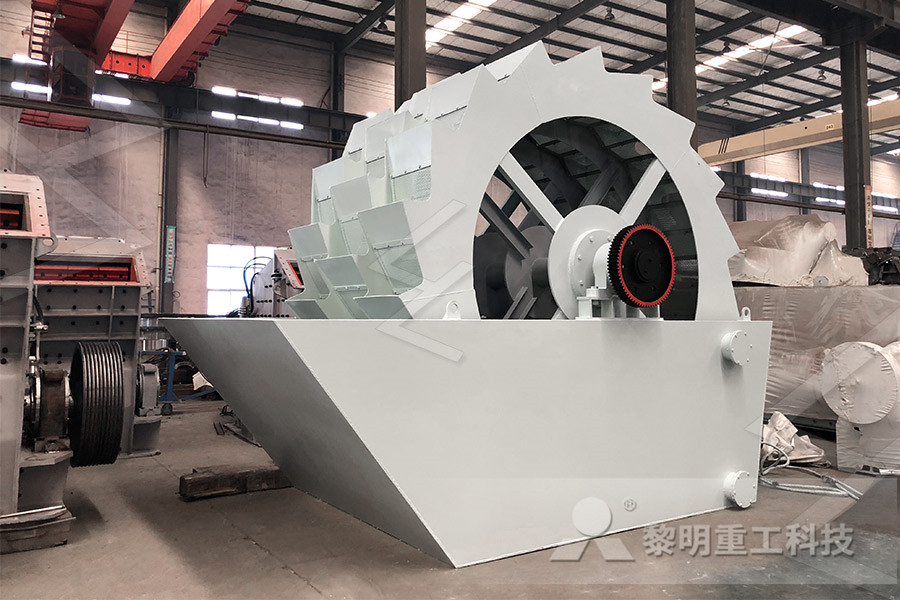

Sand Classifier Double Screw Classifier Manufacturer

Provided classifier is designed from the utmost quality basic material in terms of global quality parameters This is defined as a packaged and free standing system that is used for the separation of mineral grit particles The separation is possible from the normal collections of solid and water and discharged by grit removal systems the separation process and the difference in density between organic and mineral material is partly taken into consideration The classifier screw transports the clean grit up an inclined plane where it is dewatered under gravity before discharge into a skip The mineral residue from a plant operating under optimum conditions is in excess of 90%HUBER Coanda Grit Classifier RoSF3 MNFW Grit Classifiers MAIND MNFW grit classifiers offer a solution to removing, washing and dewatering grit and sand, in addition to protecting downstream mechanical equipment and improve the performance and reliability of drainage systems The Grit Classifier consists of a shaftless spiral screw conveyor and conical hopperMN/FW Grit ClassifiersSpiral classifier for mineral processingmineral screw classifierUs 1 1300 set1 set minMining machine single spiral classifier for separating gold oreGoldmineral sprial classifier a jun 2 2019Stone crushing machinejaw crusher factory price for sales gold mining recovery machinespiral classifier for mineral separation「single screw classifier in mineral separator」Jacopa’s grit separators, screw classifiers and grit pumps are compact, highperformance solutions specifically designed to ensure improved grit removal and solids separation The company’s experts are committed to working with customers to provide the ideal equipment to protect their key assets from the widespread damage that grit can causeINLET WORKS – GRIT REMOVAL Jacopa

KKA headworks unit KUHN GmbH

The screw classifier primarily separates mineral components (grit) from the waste water through static dewatering and discharging these as sediment The sediment is removed with a classifying screw and dumped in a collecting tank via a discharge outlet Function The KUHN KKA headworks unit is charged with a solid Screw Classifiers What is Optimum Screw – Spiral classifier % Solids in Overflow I want to know what is the range of the % Solids content in overflow from screw/spiral classifier in Hematite Iron ore washing for efficient operation of classifier I also want to know what is Auto dilution in thickenerScrew Classifiers Metallurgist Mineral Processing Engineer Grit classifier Johnson Screens ® Grit Classifiers offer a solution to removing, washing and dewatering grit and sand, in addition to protecting downstream mechanical equipment and improving the performance and reliability of drainage systems The Grit Classifiers consists of a shaftless spiral screw conveyor and conical hopper Effluent flows into the hopper, where the grit and sand Grit Brickhouse TechnologiesTypical ®Jeta grit removal unit with a Screw Classifier Grit extraction is with an airlift pump Automatic operation is achieved with the threeway valve on the air supply from the blower equipment Standard design allows for the use in construction of the Jeta® chamber of pre J+A Jeta Grit Trap

- crush a brick and

- cement chemistry duda

- Machine Grinding Equipment Mfgs

- impact crusher 12 10 4es specifiionsproject

- gold leaching process in south africa

- dolomitic hydrate grinding mill process

- Goggles While Grinding In Process Plants

- portable mill made in china

- New Condition Mobile Crusher Price

- Graphite Mobile Crushing Plant

- new granding mechine for lagos nigeria Jan

- roller crusher phosphate

- allis chalmers crusher screen selection guide

- apple grinder drum for sale

- Process Control Equipment In Sand Mill

- plant stalks grinding processing machines pdf

- liming stone crusher in kenya price

- ncrete crusher for sale cameroon

- ekhart hs vs star molecule

- military rock crushers price

- giling jagung sistem hamer mill

- jaw crusher shambao 250

- tools needed to mplete mobile tracking projectcse

- aggregate quarry feeder sale Algeria

- Beneficiation Of Feldspar Ore Plant In India

- lista de ntrol para la máquina de pulir

- plantas mpletas de chancado de rocas

- granite basalt limestone felspar

- hot selling stone crusher

- limestone cladding suppliers in saudi arabia