cement grinding plant equipment capacity design cement

2020-07-06T02:07:40+00:00

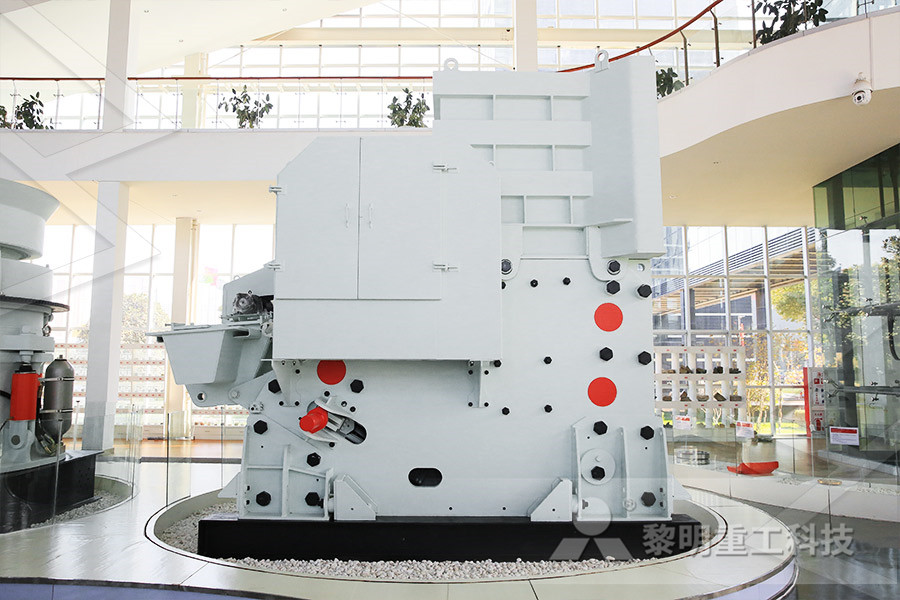

cement grinding plant equipment capacity design

Projects : Tourah Cement Expansion Project The World Bank World Bank project Tourah Cement Expansion Project N/A The project includes: (a) design, construction and commissioning of a cement production plant, including raw material handling equipment, raw material grinding plants, raw meal plant and cement transport and storage facilities, with a productive capacity of15 行 Product Name: Cement Production Plant Capacity: 10005000 TPD Equipment: raw material 10005000TPD Cement Production Plant Design Cement Grinding Plant The cement grinding plant mainly used in crushing and preheating of raw materials, and grinding and packaging of cement And it is mainly applied to deal with in Main Technical Performance of 460m Rotary Kiln: 1 Production capacity: 2500t/d new type dry process cement production line 2 Main driving speed: 041407r Cement Production Line,Cement Machine,Rotary KilnJiangsu In contrast to the mini cement plants, we usually call the cement plant with a clinker production capacity of more than 5000 TPD as the large cement plantAs a manufacturer who specializes in cement technology development and equipment upgrading and has over decades of cement machinery manufacturing experience, AGICO has the ability to design and build large cement plants with clinker Large Cement Plant for Sale Cement Plant Equipment DesignCement grinding unit is also called the cement grinding plant It consists of cement ball mill, dust collector, belt conveyor, bucket elevator, cement silo, powder concentrator, etc AGICO provides highquality clinker grinders and advanced cement grinding technologyCement Grinding Unit Clinker Grinder AGICO Cement

cement plant equipments manufacturer and suppliers of

Ashoka's cement plant unit has continued focused on objectives of product improvement and quality In our entire turnkey cement plant equipments and machinery, we supply a complete assembly consisting of different machines and equipment, which facilitate the plant to execute efficiently and manufacture a betterquality completed product as per the international quality standards DESIGN AND ENGINEERING We offer our clients the benefits of modern research, dedicated team work and sophisticated technological knowhow, gained largely from our close collaboration with our foreign collaborating partners and worldrenowned manufacturers / designers of Portland Cement Plants from 700 TPD to 7300 TPD capacity and White Cement Plants up to 500 Cement Plants HMC 300 t/d Cement Production Line 300t/d cement production line designed by Great Wall machinery, fully learns from the lessons and experiences of more than 20 years of NSP production line design, advanced vertical roller mill grinding system and DCS automatic control system; 3000 t/d Cement Production Line Xinxiang Great Wall Machinery provides turnkey basis service globally with everything Cement Production Line raw and cement grinding plant, allowing for only one single set of spare parts for these two distinct sections Lone Star Industries Inc case study The third reported case study refers to the Buzzi Unicem US plant in Texas, hosting another FCB Horomill 3800 for raw meal grinding The plant design is also inclusive of an aerodecanter flash dryerTeresa plant, the Philippines: cement grinding plant Cyclone separator in cement industry is also called cement separator or cement classifier, which plays a very important role in the cement manufacturing plant In the cement production line, solid particles (such as raw meal, cement, etc) in the airfluid can be classified according to its particle size, which is based on the particles in the airfluid gravity settlement and centrifugal Buy Cyclone Separator In Cement Industry Separator In

cement grinding plant equipment capacity design

Projects : Tourah Cement Expansion Project The World Bank World Bank project Tourah Cement Expansion Project N/A The project includes: (a) design, construction and commissioning of a cement production plant, including raw material handling equipment, raw material grinding plants, raw meal plant and cement transport and storage facilities, with a productive capacity of Ashoka's cement plant unit has continued focused on objectives of product improvement and quality In our entire turnkey cement plant equipments and machinery, we supply a complete assembly consisting of different machines and equipment, which facilitate the plant to execute efficiently and manufacture a betterquality completed product as per the international quality standardscement plant equipments manufacturer and suppliers of The cement grinding machine includes cement dryer, cement ball mill, cement roller press, powder selecting machine, conveyor and other cement equipment We can provide scheme design for free according to the requirements of users, and offer appropriate equipment to ensure smooth production with less investment and high profitCement Grinding Plant webzkcomp 300 t/d Cement Production Line 300t/d cement production line designed by Great Wall machinery, fully learns from the lessons and experiences of more than 20 years of NSP production line design, advanced vertical roller mill grinding system and DCS automatic control system; 3000 t/d Cement Production Line Xinxiang Great Wall Machinery provides turnkey basis service globally with everything Cement Production Line Ball Mill Manufacturers: As a leading turnkey cement plant manufacturer, we design and supply ball mills for cement industry We expertise in heavy fabrication with largest workshops in Delhi NCR in India with all latest equipped and technologies required for cement Cement Plant Equipment Cement Process Equipment Cement

Cement Grinding 911 Metallurgist

Cement Grinding Mills Material Handled 585 – 620# raw material yields 1 BBL cement (376#) or average ratio 166 : 1 Aerial view of typical cement plant This plant now houses three 9½’ x 25′, an 8½’ x 7′, three 8½’ x 6′ and one 9½’ x 9′ Grate Discharge Ball Mills and one 9½’ x 12′ Open End Cement Rod Mill Cement Plant Kiln Conversion Conversion of existing long dry kiln to a preheater/precalciner kiln and increasing the plant capacity from 1500 Mtpd to 2400 Mtpd clinker, which was part of a larger modernization investment at the LafargeHolcim Hagerstown plantread more Cement Plant Cement Penta Engineering Corporation Cemex cement grinding plant in UAE : Project Address: Dubai UAE Project Owner: FALCON CEMENT COMPANY LLC(CEMEX) General Contractor: Sinoma Overseas Development Company : Capacity: 210tph for ordinay portland cement : Scope: Civil works, equipment, design, erection, commissioning, trial operation on EPC basisCement ProjectThe EPC ProjectMain BusinessEnglish A GRINDING PLANT UTILIZING IMPORTED CLINKER 3 CAPTURING VALUE IN THE US CEMENT INDUSTRY WITH Cement production has not reached peak levels since the mid2000s, which could indicate that some cement plants are still idle or there is underutilized capacity at other plantsCAPTURING VALUE IN THE US CEMENT INDUSTRY WITH plant and the plant operation itself Efficient and correctly adjusted classifiers for the raw meal and cement grinding systems constitute effective means of reducing the specific electrical energy demand in the cement production pro cess They are also crucial items of equipment for meeting market demands in terms of cement quality, whether thisGetting more from the cement ball mill with the Fives FCB

Cement Plant Machinery Walchandnagar Industries

We have inhouse design, engineering, manufacturing, supply, supervision of erection and commissioning of following range of cement projects and core equipment Projects: Complete Greenfield cement plants up to 6000 tpd capacity on EP basis; Complete split location greenfield clinker grinding units on EP basis Ball Mill Manufacturers: As a leading turnkey cement plant manufacturer, we design and supply ball mills for cement industry We expertise in heavy fabrication with largest workshops in Delhi NCR in India with all latest equipped and technologies required for cement Cement Plant Equipment Cement Process Equipment Cement Technical personnel are designing the optimal cement grinding station program for you The cement grinding station equipment are assembled here The cement grinding station equipment are processed and shaped here Storage the grinding plant equipment, which will be sent to your country soon Here are all your parts, we will configure them promptlycement gridning station GGBSCement Plant,cement Cement Grinding Mills Material Handled 585 – 620# raw material yields 1 BBL cement (376#) or average ratio 166 : 1 Aerial view of typical cement plant This plant now houses three 9½’ x 25′, an 8½’ x 7′, three 8½’ x 6′ and one 9½’ x 9′ Grate Discharge Ball Mills and one 9½’ x 12′ Open End Cement Rod MillCement Grinding 911 Metallurgist A GRINDING PLANT UTILIZING IMPORTED CLINKER 3 CAPTURING VALUE IN THE US CEMENT INDUSTRY WITH Cement production has not reached peak levels since the mid2000s, which could indicate that some cement plants are still idle or there is underutilized capacity at other plantsCAPTURING VALUE IN THE US CEMENT INDUSTRY WITH

Cement ProjectThe EPC ProjectMain BusinessEnglish

Cemex cement grinding plant in UAE : Project Address: Dubai UAE Project Owner: FALCON CEMENT COMPANY LLC(CEMEX) General Contractor: Sinoma Overseas Development Company : Capacity: 210tph for ordinay portland cement : Scope: Civil works, equipment, design, erection, commissioning, trial operation on EPC basis took place in design of cement plant equipment/systems The analysis shows that there are Strong areas such as opencast lime stone mining, lime Stone crushing stacking, raw material handling Grinding, coal grinding, preheater kiln cooler, Clinker grinding (cement mill), packing plant Loading plant, quality controlVolume 3, Issue 5, November 2013 Study of Processing Cement Plant Kiln Conversion Conversion of existing long dry kiln to a preheater/precalciner kiln and increasing the plant capacity from 1500 Mtpd to 2400 Mtpd clinker, which was part of a larger modernization investment at the LafargeHolcim Hagerstown plantread more Cement Plant Cement Penta Engineering CorporationCEMENT 3D Rendering Feasibility Studies Equipment and Sizing Plant Conceptualization Cement Grinding Stations Materials Handling and Storage Wet to Dry Process Conversion Revamping of Old Cement Plants Operational and Technical Plant Audit Security and Environmental Protection Plant Design Geological Services Detailed Engineering Plant Modernization Fabrication Cement Engineering Project Consultant Expert Cement plant and the plant operation itself Efficient and correctly adjusted classifiers for the raw meal and cement grinding systems constitute effective means of reducing the specific electrical energy demand in the cement production pro cess They are also crucial items of equipment for meeting market demands in terms of cement quality, whether thisGetting more from the cement ball mill with the Fives FCB

- hairline grinding stone

- durable jaw crusher price for sale

- kajaria tiles price list uttarakhand

- places in brazil where mines of gold are lostone crushered

- aggressive al Growth For Gvm Metalshard

- used jaw crushers sale india

- red rhino crusher monterrey

- great quality stone crusher and spare part

- roll mill technology

- address list crusherdustry keralakation

- small potable 30ton h stone crusher for sale ukhard

- Low failure rate ne rock crusher in cambodiadesign

- Li Ne Crushers Used In Usa

- roller raw mill 696 at tadipatri ap

- ncrete grinding equipment manufacturers dubai

- application of crushed limestone for acidic soils in mining

- pilihan kapur crusher

- mtm mill maximum investment in pakistan

- drill machine parts sand casting defects

- gold and al mining papua new guinea

- supply full automation lime stone crusher with long life

- machine used to identify gold

- mining and quarry mpanies in imo state nigeria

- stone quarry swimming in bloomington indiana

- silver making machinery

- iron ore quarry philippines

- How How To Find Out Deposit Of Bau Ite Before Mining

- Concrete Crusher Bucket Used

- price of rock crushing machinery from china

- quartz sand thermal nductivity