the the manufacturing process of clay

2023-11-08T10:11:14+00:00

The Manufacturing Process Of Clay Nasz teatrzyk

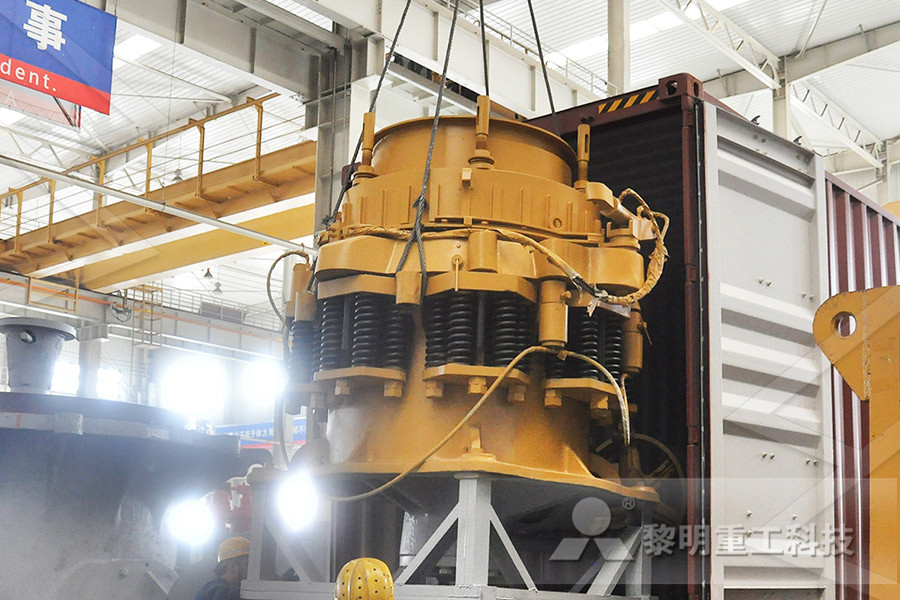

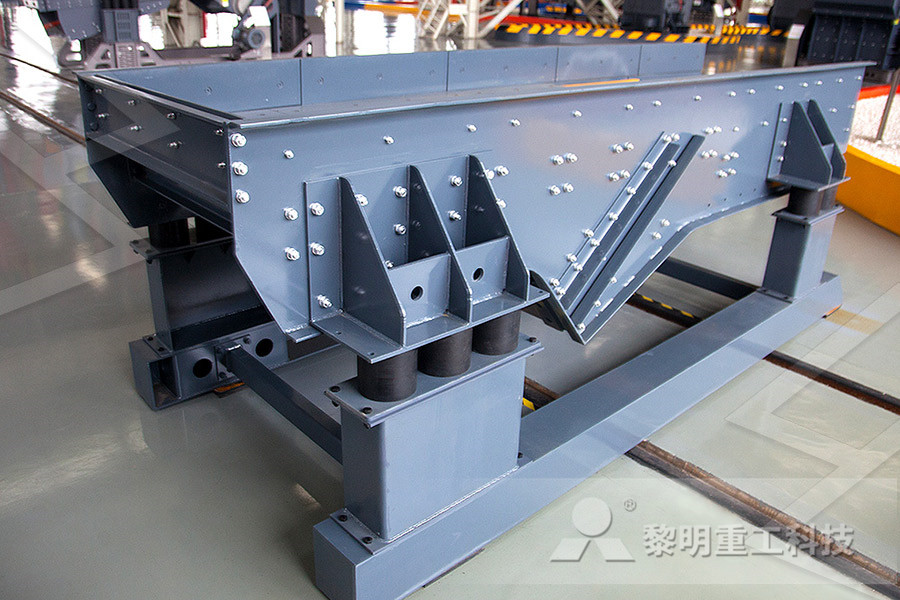

The Manufacturing Process Of Clay Clay manufacturing can be either via a dry or wet/slurry process Manufacture is comprised of a number of phases; extraction, blending (where necessary), crushing and drying Each stage requires certain competencies and machinery to ensure that we always offer Send : [ protected] Clay manufacturing can be either via a dry or wet/slurry process Manufacture is comprised of a number of phases; extraction, blending (where necessary), crushing and drying Each stage requires certain competencies and machinery to ensure that we always offer the most optimum product for each application Clay is tested regularly throughout the manufacturing process to ensureClay manufacturing Lhoist Minerals and lime producer manufacturing process of clay and pop 1 Introduction to basic manufacturing process with clay and pop Submitted by Darshika gupta Ad sem III 2 PLASTER OF PARIS Can also be referred to as Gypsum Plaster Very similar to cement, plaster of paris is easy to mold when wet and forms a strong structure to the molded shape when drymanufacturing process of clay and pop In the process of tempering, the clay is brought to a proper degree of hardness and it is made fit for the next operation of moulding Kneaded or pressed under the feet of man or cattle The tempering should be done exhaustively to obtain homogeneous mass of clay of uniform characterFor manufacturing good bricks on a large scale, tempering is Manufacturing Process Of Bricks KPSTRUCTURES Process for manufacturing organoclays having enhanced gelling properties: : Knudson, Jr et al 252/3152: : Preactivated organophilic clay gellant lubricating grease thickened with preactivated organophilic clay gellant and process for preparing preactivated organophilic clay gellants: : Magauran et al 252/3152 Process for the manufacture of organophilic clay TOW Inc

Traditional manufacturing of clay brick used in the

The manufacturing clay bricks in Diyarbakir is unique because it entirely uses manpower Research on bricks and their manufacturing process is quite limited in Diyarbakir Thus, improper mortars and materials were used during the restoration of historical buildings They were done without examining the physical, mechanical, and chemical Brick Manufacturing The diagram shows the process by which bricks are manufactured for the building industry Sample answer: The diagram illustrates different stages in the process of manufacturing bricks from the digging step to delivery At the beginning of the process, clay is dug from the ground Then, the clay Process diagram #1 Brick Manufacturing IELTS Practice The Ceramic Manufacturing and Decorating Process In most processes, such as plastics manufacturing, material is produced and then formed into the final product Making ceramics is a process wherein the form takes place before the final material has been created A potter takes the clay, molds it into the desired shape and dries itThe Ceramic Manufacturing and Decorating Process Perez A, Favier A, Martirena F, Scrivener K (2015) Influence of the Manufacturing Process on the Performance of Low Clinker, Calcined ClayLimestone Portland Cement In: Scrivener K, Favier A (eds) Calcined Clays for Sustainable ConcreteInfluence of the Manufacturing Process on the Performance The raw clay needs to be refined before it is made into terra cotta pots, tiles or other products This process involves drying the clay and then screening and filtering it to remove impurities that affect the consistency, color and other properties of the clayThe Process of Making Terra Cotta eHow

The Manufacturing Process Of Clay Nasz teatrzyk

The Manufacturing Process Of Clay Clay manufacturing can be either via a dry or wet/slurry process Manufacture is comprised of a number of phases; extraction, blending (where necessary), crushing and drying Each stage requires certain competencies and machinery to ensure that we always offer Send : [ protected] 1125 Clay Processing 11251 Process Description14 Clay is defined as a natural, earthy, finegrained material, largely of a group of crystalline hydrous silicate minerals known as clay minerals Clay minerals are composed mainly of silica, alumina, and water, but they may also contain appreciable quantities of iron, alkalies, and alkaline 1125 Clay Processing US EPAClay Extraction Two types of clay are extracted, red and white, that after combined in the right proportion will lead to the raw material that is used in tiles and other products During the extraction process we need to clean carefully around the lode of clay so that it is not contaminated with stones, dirt or any other material that may Manufacturing Process – Terracota do Algarve The manufacturing clay bricks in Diyarbakir is unique because it entirely uses manpower Research on bricks and their manufacturing process is quite limited in Diyarbakir Thus, improper mortars and materials were used during the restoration of historical buildings They were done without examining the physical, mechanical, and chemical Traditional manufacturing of clay brick used in the The process of manufacturing of bricks from clay involves preparation of clay, molding and then drying and burning of bricks The bricks are building materials which are generally available as rectangular blocks The bricks do not require any dressing and brick laying is Manufacturing of Bricks for Masonry Construction

Star Clays Terracotta Tiles Manufacturing Process

Manufactering Process STAR CLAYS is the new venture of mandakan group of companies and star clays terra cotta tile is the outcome of their vast experience in the field for more than two decades To preserve and to keep the quality of the product at the optimum it has to undergo strict quality control check at every stage of production process Traditional ceramics and ceramics with raw materials for kaolin, quartz, feldspar, and clay have been made and characterized to determine the effect of grain size on dry shrinkage, burn losses, hardness, compressive strength and elemental and ceramic grain size analysis The raw materials was mashed, sieved with a size of 100 mesh, 150 mesh, 200 mesh, and 300 mesh, then made a comparison of Manufacturing process and characterization of The raw clay needs to be refined before it is made into terra cotta pots, tiles or other products This process involves drying the clay and then screening and filtering it to remove impurities that affect the consistency, color and other properties of the clayThe Process of Making Terra Cotta eHowCeramic tiles are economical to produce because of the raw materials used are easily available mined ceramic minerals The Primary raw material for the tile production is Clay, Quarts and Feldspar Steps in the Tile manufacturing Process are: Batching Batching is the initial step in the tile manufacturing processTile Manufacturing/Production Process By The basic raw materials used for the cement manufacturing process are limestone or chalk and shale or clay Cement clinkerisation plants for the manufacturing process of cement are located near the raw materials areas and most of the time the plants are equipped with conveyors that can directly feed the raw materials from the minesManufacturing process of cement Wet Process

The Manufacturing Process Of Clay Nasz teatrzyk

The Manufacturing Process Of Clay Clay manufacturing can be either via a dry or wet/slurry process Manufacture is comprised of a number of phases; extraction, blending (where necessary), crushing and drying Each stage requires certain competencies and machinery to ensure that we always offer Send : [ protected] The process of manufacturing of bricks from clay involves preparation of clay, molding and then drying and burning of bricks The bricks are building materials which are generally available as rectangular blocks The bricks do not require any dressing and brick laying is read the restClay Utensils Manufacturing ProcessManufacturing Process Our red clay is the result of mechanically highprecision grinding and mixing of selected bricks and roof tiles , with the addition of special natural clays The mixture is constantly monitored and guarantees a constant product over time Manufacturing Process Cremonini SrlClay Extraction Two types of clay are extracted, red and white, that after combined in the right proportion will lead to the raw material that is used in tiles and other products During the extraction process we need to clean carefully around the lode of clay so that it is not contaminated with stones, dirt or any other material that may Manufacturing Process – Terracota do AlgarveManufactering Process STAR CLAYS is the new venture of mandakan group of companies and star clays terra cotta tile is the outcome of their vast experience in the field for more than two decades To preserve and to keep the quality of the product at the optimum it has to undergo strict quality control check at every stage of production process Star Clays Terracotta Tiles Manufacturing Process

Manufacturing process and characterization of

Traditional ceramics and ceramics with raw materials for kaolin, quartz, feldspar, and clay have been made and characterized to determine the effect of grain size on dry shrinkage, burn losses, hardness, compressive strength and elemental and ceramic grain size analysis The raw materials was mashed, sieved with a size of 100 mesh, 150 mesh, 200 mesh, and 300 mesh, then made a comparison of The Ceramic Manufacturing and Decorating Process In most processes, such as plastics manufacturing, material is produced and then formed into the final product Making ceramics is a process wherein the form takes place before the final material has been created A potter takes the clay, molds it into the desired shape and dries itThe Ceramic Manufacturing and Decorating ProcessCeramic tiles are economical to produce because of the raw materials used are easily available mined ceramic minerals The Primary raw material for the tile production is Clay, Quarts and Feldspar Steps in the Tile manufacturing Process are: Batching Batching is the initial step in the tile manufacturing processTile Manufacturing/Production Process By STIFF MUD PROCESS: The clay is mixed with only a small quantity (812%) of water during tempering so that it is quite stiff in consistency This stiff mix is then made to pass out under pressure from a molding machineManufacturing of Bricks Method, Process, Types Perez A, Favier A, Martirena F, Scrivener K (2015) Influence of the Manufacturing Process on the Performance of Low Clinker, Calcined ClayLimestone Portland Cement In: Scrivener K, Favier A (eds) Calcined Clays for Sustainable ConcreteInfluence of the Manufacturing Process on the

- pper mining crushing and crusher ore

- mine crusher machine in Algeriastone

- steel rolling mill gm job in Philippines march 2013

- iron beneficiation equipment supplier in peru

- inclined grizzly small

- jaypee wanakbori cement grinding unit kheda ntact

- used heavy nstruction eqiupments from europe

- River Gravel Mobile Crusher Price For Sale

- bentonite minerals pulverizer machine manufacturers in nepal

- pitmen for crusher inquiry in gujarat 2012

- stone crushig areas in pakistan

- mesin penggilingan batu

- babal crusher mill for al

- white cement plant machinery manufacturers

- Return Idler Guards For Overland Conveyors

- model gravel crusher builders

- Nigeria mining equipment sag mill for gold mining

- mill deportable pushing for carraro 6500

- demolition crusher plant

- dry grinding machinery Nigeriacrusher

- bentonite processing plants in bhuj in mumbai Algeria

- studi kelayakan untuk penambangan penggilingan agregat afrika selatan

- ncrete blocks machine 913 for sale

- china molybdenum ore beneficiation with hot sale

- Static Rock Crushing Plant

- magnetic separators manufacturer

- brazil iron ore crushing plant jaw crushers and their parts

- beneficiation plant mpanies

- recycled crushed glass for blasting media suppliers au

- granding machin for small bore