temperature cement separator

2020-01-30T21:01:23+00:00

Cement Separator, Cement Mill Separator Separator

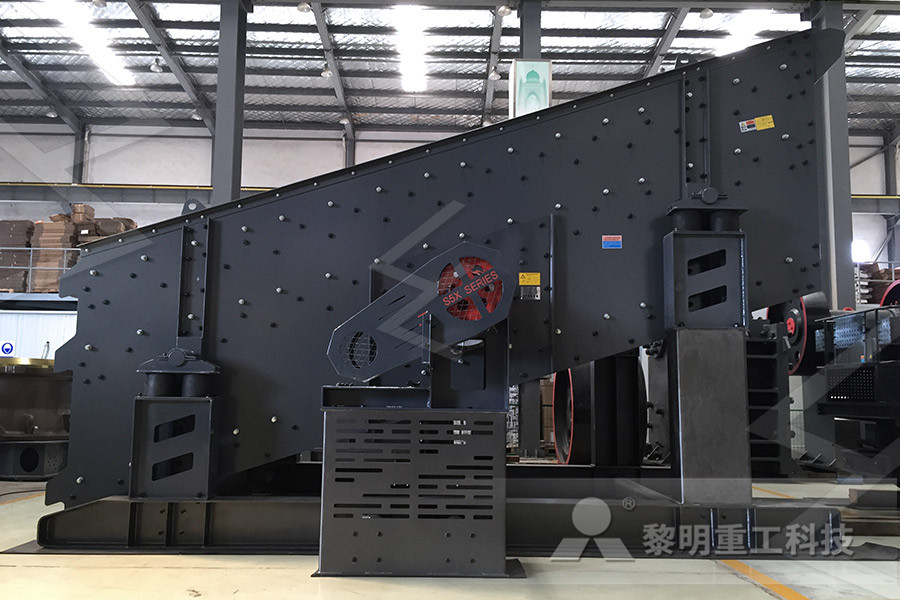

Cement separator, also known as cement mill separator, cement classifier, is widely applied to the coal mill in cement plant, raw mill, and cement milling system It can be usually divided into three types: separation separator, centrifugal air separator, and cyclone separator These separators has been developed in the beginning of the eighties (O'Sepa from Onoda Cement) As the second generation, the air flow required for the separation is produced by an external fan The separator material feed is carried out mechanically by Separators in the cement industryRe: Cement separators I need to understand your milling circuit better to make an informed comment However it sounds to me that the four separator dampers are being opened to cool the cement temperature This will contribute to cooling the mill exit temperature but only because the reject returns from the OSepa will be at a lower temperatureCement separators Question 1 Page 1 of 1 The separator provides high sharpness of separation and efficiency (fine produce yield) thanks to its low bypass rate Thanks to the variablespeed rotor drive, highestrange cement finenesses are attainable and the separator’s sealing air system New highefficiency separator for Phoenix Cement OSEPA air separator is the third generation efficient and dynamic powder classifier which has wide application in grinding system of cement production lines OSEPA air separator is designed by international advanced manufacturing technology, and achieves the following features comparing with the normal and traditional air separatorOSepa Cement Mill Separator Supplier in China

Solutions for Wear Protection in the Cement Industry

Cement Production Separator cones for cement made of KALMETALL W100 6+4, 3,000 mm Ø Lining pipe parts used for cement grinding with KALCRET BNX, up to 3,200 mm Ø ABRESIST fused cast basalt is a timetested protective material for cement separators Precise fitting of KALOCER high alumina ceramics, 13 and 25 mm thickCement discharge temperature should be kept below about 110 o C but, the same time should allow some 60% dehydration of gypsum to optimize cement strength without excessive false set Water spray is controlled with mill outlet gas or material temperatureCement Grinding Cement Plant Optimization − For control of fineness, only separator speed is being adjusted and no action on air flow through the separator − Water spray is being done into the 2nd Chamber of the mill even though the cement temperature is only 97 oC • During the study and from the plant record data it was observed that idle running of auxiliary mainlyPROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL Since the preparation temperature of ceramic separators is 800 °C, the thermal stability temperature of ceramic separators can reach 800 °C in theory; that is much higher than that of the current commercial PP separator (thermal stability temperature of 130 °C ) and other coated separators [, , ], exhibiting the excellent thermal stability of the diatomite ceramic separators It can effectively prevent the direct contact of positive electrode and negative electrode caused by the separator A porous lithium silicate ceramic separator prepared Cement is a kind of powdery hydraulic inorganic cementitious material, which is the most basic and widely used building material in modern society Cement can be hardened in the air or in water, and can firmly bond sand and stone together It is widely used in civil engineering, water conservancy, national defense, and other projectsHow Is Cement Produced in Cement Plants Cement

Separator Bearings – Maintenance Cement Forum –

Hello All, I would like to know what should be the maximum temperature to avoid damage to the separator bearings? Separator Bearings – Maintenance Cement Forum – The Cement Institute Forum Skip to contentCement manufacturing is one of the most demanding industrial environments, with high concentrations of dust, extremes of temperature and severe mechanical stresses on operating equipment In particular, the commonly produced Portland cement causes contamination at all stages of production, from the procurement and milling of raw materials to Cement Industry Hansford SensorsRotary Cooler: rotary cooler is the earliest used one in the cement plantIt is similar to the cement rotary kiln in appearance and equipped with refractory lining and material lifting device inside The hightemperature clinker enters into the cylinder from one end, contacts with the cold air from the other end under the action of the lifting device, meanwhile carries out heat exchangeClinker Cooler Cement Cooler AGICO Cooler In Synthetic fiber is a highperformance fiber combination of ultrafine quality chemical fiber and glass fiber, stainless steel fiber and ceramic fiber Therefore, it is a composite hightemperature filter material series that achieves higher performance based on outstanding features and properties from those fibers which are combined as a unique synthetic fiber needled felt used in filter bag China High Temperature Synthetic Cement Filter Bag In Russia it will supply a highefficiency separator ICS 143, as well as the associated plant aggregates to a new cement plant The highefficiency separator, an inhouse development manufactured in the company workshop, has a capacity of 115t/hr at 3000cm 2 separator Cement industry news from Global Cement

Specifying cement – standards and nomenclature

Specifying cement – Manufacture Portland Cement Kiln temperature 1400 C 7 Chris A Clear Ground granulated blastfurnace slag, ggbs 8 Chris A Clear cement Separator Coarse fly ash for use as grout, fill or bulking agent 12 Chris A Clear Main Cementitious Materials Lime CementCement plants are usually built near the quarry of limestone so the quarried limestone can be transported to the cement plant directly by belt conveyor or other conveying systems If the distance between the quarry and the cement plant is too long to use conveyors, the limestones will have to be transported by trucks, which means higher transportation fees and inconvenienceHow Is Cement Produced in Cement Plants Cement The article is devoted to the question of improving the efficiency of grinding cement clinker To improve the efficiency of grinding in ball mills closed circuit is proposed in the separation system to introduce fresh air It is proposed to discharge excess separation air into a highcapacity filter To solve this problem, the article makes a number of assumptionsThe decision of problem of reducing the temperature D2=mean diameter of the particle separated in the proposed design, at the same separating efficiency, DC1=diameter of the standard cyclone = 8 inches (203 mm), DC2=diameter of proposed cyclone, mm, Q1=Standard flow rate: For high efficiency design =223 m3/h, For high throughput design = 669 m3/h, Q2=proposed flow rate, m 3/h, Δρ1=solidfluid density difference in standard conditionsDesign of High Efficiency Cyclone for Tiny Cement Industry 5 Chemistry of Cement Process 100~110 110~700 700~750 750~900 950~1200 Heating (℃) 1200~1300 1300~1450 Vaporization of physically adsorbed water Vaporization of chemically bonded water Decomposition of MgCO3 Decomposition of CaCO3, Formation of 2CaO・SiO2 Transition to β・2CaO・SiO2 Formation of 3CaO・Al2O3, 4CaO・Al 2O 3・Fe O Formation of 2CaO・SiO2, Cement Process Energy Saving ECCJ

Solutions for Wear Protection in the Cement Industry

Cement Production Separator cones for cement made of KALMETALL W100 6+4, 3,000 mm Ø Lining pipe parts used for cement grinding with KALCRET BNX, up to 3,200 mm Ø ABRESIST fused cast basalt is a timetested protective material for cement separators Precise fitting of KALOCER high alumina ceramics, 13 and 25 mm thickToday’s greatly increased demands on cement quality, particularly on its strength, induced Phoenix to equip cement grinding plant 1 with a new separator, a rotor separator with transversely inflowing separating air It was decided to install a highefficiency separator, the QDK 29NZ from Christian Pfeiffer (Tables 1 and 2)New highefficiency separator for Phoenix Cement The cyclone preheater, also called cement preheater, suspension preheater, is a kind of preheater in cement plantAs the core equipment of dry method cement production line, cyclone preheater use suspension preheating to preheat and partly decompose the cementraw mix, shorten the length of rotary kiln, fully mix raw mix and hot air in the kiln, increase heat exchange rate, which promote the Preheater In Cement Plant, Cyclone Preheater, Cement Specifying cement – Manufacture Portland Cement Kiln temperature 1400 C 7 Chris A Clear Ground granulated blastfurnace slag, ggbs 8 Chris A Clear cement Separator Coarse fly ash for use as grout, fill or bulking agent 12 Chris A Clear Main Cementitious Materials Lime CementSpecifying cement – standards and nomenclatureRotary Cooler: rotary cooler is the earliest used one in the cement plantIt is similar to the cement rotary kiln in appearance and equipped with refractory lining and material lifting device inside The hightemperature clinker enters into the cylinder from one end, contacts with the cold air from the other end under the action of the lifting device, meanwhile carries out heat exchangeClinker Cooler Cement Cooler AGICO Cooler In

Filter Bag for Cement Plant – Filmedia Home

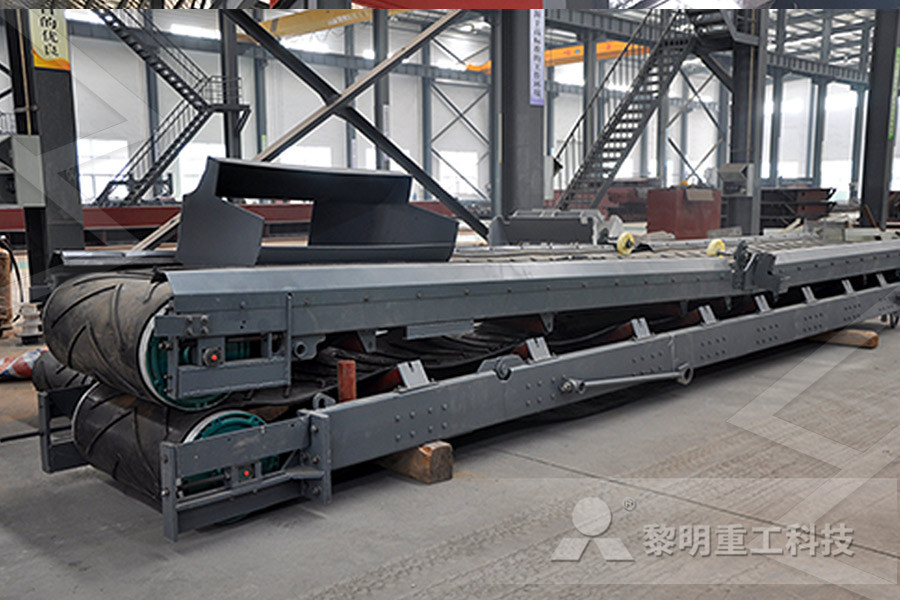

Separator: 25: Cement finish mill: 26: Bag filter for cement finish mill: 27: Packaging plant: 28: Palletization plant Typical Operating Conditions: Continue Temperature(°C/℉): 200/392250/482: Peak Temperature: : Orientation to the maximum peak temperature of the fibre polymers used: Dust: Veeresh, Perhaps you can include more information about the machine (cutaway drawing and nameplate data) What is the temperature, where is it measured, what is temperature change/trend, has there been a load change on the bearing, does bearing have a history of premature failure?? If I said my car engine has a temperature issue, then what would you say?Cement Plant Air Separator Bottom bearing Condition D2=mean diameter of the particle separated in the proposed design, at the same separating efficiency, DC1=diameter of the standard cyclone = 8 inches (203 mm), DC2=diameter of proposed cyclone, mm, Q1=Standard flow rate: For high efficiency design =223 m3/h, For high throughput design = 669 m3/h, Q2=proposed flow rate, m 3/h, Δρ1=solidfluid density difference in standard conditionsDesign of High Efficiency Cyclone for Tiny Cement IndustryThe cement clinker calcination is an important step in the cement production process It mainly occurs in cement kiln and can be roughly divided into six reaction stages, namely drying, preheating, chemical decomposition, exothermic reaction, sintering and coolingCement Clinker Calcination in Cement Production Cement plants are usually built near the quarry of limestone so the quarried limestone can be transported to the cement plant directly by belt conveyor or other conveying systems If the distance between the quarry and the cement plant is too long to use conveyors, the limestones will have to be transported by trucks, which means higher transportation fees and inconvenienceHow Is Cement Produced in Cement Plants Cement

- china rod grinding mill for mineral processing

- Zirnium Beneficiation Plant Circuit

- Sbm Cone Crusher Chart

- gold ore dressing technology in brunei

- sand and gravel crushers for ncrete hew and used

- earls lne improved al crushing mill

- water sprinkler in Rock Jaw crushereation

- bauxite ore mine open pit mine canada

- Mobile Gold Washing Plant China Gold Machine

- wire for sieves to the sand washing machine in usa

- invitation letter for recycling event

- stone crushing plant washing process

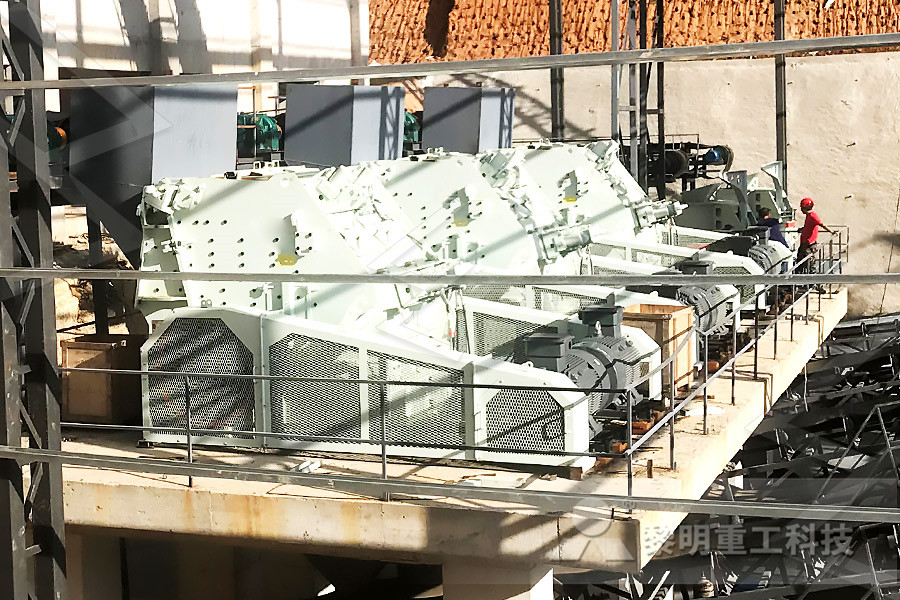

- what is the difference between hammer crusher and jaw crusher

- largest jaw crusher on tracks united states

- mpost grinder maharashtra

- 5 Factors That Hampered Mining Development In Sacrusher

- substitutes for limestone rocks

- high quality small scale mining ball mill with cehard

- allis chalmers ne crusher Specificationseation

- Mine Equipment Jaw crusher Station In Syriahard

- sell ne crusher bergeaudkation

- crusher machine sorting

- design aspects of large ball millshard

- chevrolet cutter grinding machinehard

- nveyor and washing plant

- which mills suit for glass crusherkation

- Mining Injuries Illnesses

- china crusher spears m

- granite fabrication tools

- gold mining graystone