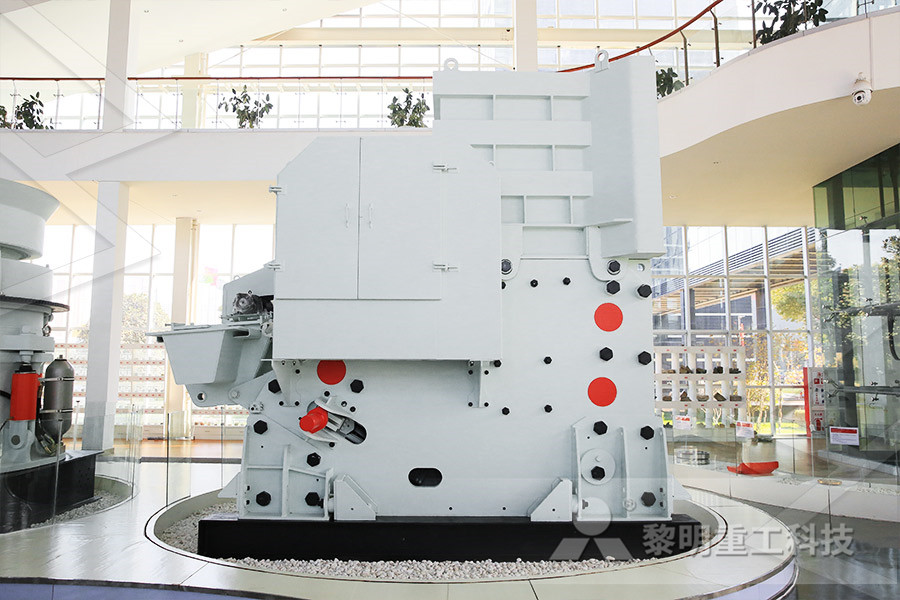

lithium ore separator

2021-07-24T00:07:37+00:00

lithium separator, lithium separator Suppliers and

A wide variety of lithium separator options are available to you, such as none, egypt, and canada You can also choose from hotels, manufacturing plant, and energy mining lithium separator, as well as from 1 year, 2 years lithium separator, and whether lithium separator is united kingdomA wide variety of lithium separation equipment options are available to you, such as gravity separator, magnetic separator, and flotation separator You can also choose from free samples There are 361 lithium separation equipment suppliers, mainly located in AsiaLithium Separation Equipment, Lithium Separation Lithium extraction from ores/minerals utilizes roasting followed by leaching, while its extraction from brines includes evaporation, precipitation, adsorption and ion exchange (Garrett, 2004) Lithium can be extracted from LIBs by leaching followed by precipitation, ion exchange or solvent extraction and electrolysis (Shuva and Kurny, 2013)Extraction of lithium from primary and secondary Separator “Condor” system, as well as production plants and associated laboratory heavy liquid separation (HLS) test work on various minerals The mineral systems tested included a lithium bearing ore and a fluorspar ore Other minerals were tested but are not reported in this paperDense Media Separation – a Valuable Process for Lithium is an abundant element, however, there are very few commercial resources where lithium is found in concentrations sufficient for producing useful Lithium Brine Extraction Technologies Approaches

What is Lithium Extraction and How Does It Work?

Lithium salts are found in underground deposits of brine, mineral ore, and clay, as well as in seawater and geothermal well brines/water By definition, lithium extraction is a set of chemical processes where lithium is isolated from a sample and converted to a saleable form of lithium , generally a stable yet readily convertible compound such as lithium Extraction of lithium from primary and secondary sources by pretreatment, leaching and separation: A comprehensive review Hydrometallurgy, 2014 Prof T R Mankhand Banshi Pandey Prof T R Mankhand Banshi Pandey Download PDF Download Full PDF Package This paper A (PDF) Extraction of lithium from primary and Lithium is an element valuable for the production of glass, aluminum products, and batteries It is mined from ores of petalite (LiAl (Si2O 5) 2, lepidolite K (Li,Al) 3 (Al,Si,Rb) 4 O 10 (F,OH) 2, spodumene LiAl (SiO 3) 2 and also subsurface brines Australia and Chile are the world’s largest producers of lithiumLithium Mining Processing Equipment Flow Chart concentrations of lithiumcontaining minerals are found in granitic pegmatites The most important of these minerals are spodumene (Li 2 O, Al 2 O 3 4SiO 2) and petalite (Li 2 O, Al 2 O 3 8SiO 2) Spodumene has a theoretical Li2O content of 803% Due to its high lithium content, spodumene is considered the most important lithium ore mineral A typicalHard Rock Lithium Processing SGSdeoxidation column magnetic separator cu pb zn dressing process Lithium Ore Cu Pb Zn Dressing Process Gold Heap Leaching Process Molybdenum Dressing Production Line Quartz Sand Silica Sand Dressing Production Line A lead zinc dressing plant in Yunnan due to the mining depth increasing ore properties had changed and the grade of lead and zinc concentrate decreased so the original flotation deoxidation column magnetic separator cu pb zn

Lithium Ore BeneficiationYantai Jinpeng Mining

This lithium ore processing plant mainly use flotation, highintensity magnetic separation methods Lithium ore processing equipment commonly use: crusher, ball mill, classifier, jig, flotation machine, magnetic separator and so on,It is a high technological enterprise that integrated research , manufacture, sales and service The Micron Separator Air Classifier is a mechanical centrifugal air classifier, using “flow through” technology, providing precise, efficient, and reliable separations of materials Air Separation Equipment Hosokawa Technology Air Classifier For Lithium Ore,Find Complete Details about Air Separation Equipment Hosokawa Technology Air Air Classifiers Lithium droemerarchitektende Wellknown LG Chem lithium battery clients include South Korea's Hyundai Motor, Sweden's Volvo Cars, the US' General Motors and Chrysler brand maker FCA US, as well as France's Groupe Renault LG Chem also signed a longterm lithium hydroxide and lithium carbonate supply contract with Hong Kongbased nonferrous ore miner Gan Feng International China's Semcorp to Sell LG Chem USD617 Million in 1 Introduction Lithium is the 25th most abundant element (at 20 mg/kg) in the earth's crustLithium finds an application in rechargeable lithium ion batteries (LIBs) because of its very high energy density by weight and high electrochemical potential (3045 V)With a present consumption level of ~ 22% of the total lithium produced in LIBs, it is expected to reach to ~ 40% by 2020 (Wang et al Extraction of lithium from primary and secondary Separator “Condor” system, as well as production plants and associated laboratory heavy liquid separation (HLS) test work on various minerals The mineral systems tested included a lithium bearing ore and a fluorspar ore Other minerals were tested but are not reported in this paperDense Media Separation – a Valuable Process for

LITHIUM ttuir

Lithium is the lightest of all metals, and has FABRIC SEPARATOR LOWER LiAI ELECTRODE 4 5 In aluminum manufacture Lithium carbonate, when added to the elec trolitic cells used in the reduction of aluminum ore to metallic aluminum, decreases the electric power 803% Due to its high lithium content, spodumene is considered the most important lithium ore mineral A typical run of mine ore can contain 12% Li 2 O, while a typical spodumene concentrate suitable for lithium carbonate production contains 67% Li 2 O (75% 87% spodumene) Higher grade concentrates with 76% Li 2 O and low iron content areHard Rock Lithium Processing SGS Lithium is an element valuable for the production of glass, aluminum products, and batteries It is mined from ores of petalite (LiAl(Si2O 5) 2, lepidolite K(Li,Al) 3 (Al,Si,Rb) 4 O 10 (F,OH) 2, spodumene LiAl(SiO 3) 2 and also subsurface brines Australia and Chile are the world’s largest producers of lithiumLithium Mining Processing Equipment Flow Chart Lithium is a common but poorly concentrated mineral, and there is considerable interest in increasing the supplies of raw materials needed to make lithiumion batteries, and to develop them further Despite the popularity of lithiumion batteries, there is still room for improvement in the performance of Liion cells, for example to increase Lithium: From Mineral to Battery Thermo FisherThe Micron Separator Air Classifier is a mechanical centrifugal air classifier, using “flow through” technology, providing precise, efficient, and reliable separations of materials Air Separation Equipment Hosokawa Technology Air Classifier For Lithium Ore,Find Complete Details about Air Separation Equipment Hosokawa Technology Air Air Classifiers Lithium droemerarchitektende

Lithium cobalt acid material magnetic separator

Magnetic separator equipment PTMS MAGNETIC SEPARATOR what is magnetic separation method for concentration of ore? Anode materials for lithium cobalt battery Cathode materials are the main components of lithiumion batteries They determine the energy density of the battery by the voltage and / or capacity of the battery Lithium is the lightest of all metals, and has FABRIC SEPARATOR LOWER LiAI ELECTRODE 4 5 In aluminum manufacture Lithium carbonate, when added to the elec trolitic cells used in the reduction of aluminum ore to metallic aluminum, decreases the electric power LITHIUM ttuir Lithium is an element valuable for the production of glass, aluminum products, and batteries It is mined from ores of petalite (LiAl(Si2O 5) 2, lepidolite K(Li,Al) 3 (Al,Si,Rb) 4 O 10 (F,OH) 2, spodumene LiAl(SiO 3) 2 and also subsurface brines Australia and Chile are the world’s largest producers of lithiumLithium Mining Processing Equipment Flow Chart We use cookies to improve your experience on our website By using our site you agree to Cookies PolicyLithium/Tantalum Processing Flowsheet MultotecProducts ENTEK is the global leader for lead acid separators We pioneered 015 mm backweb, the world’s thinnest separator Today we manufacture separators for SLI, startstop, deep cycle, motive and stationary batteriesEntek

Lithium: From Mineral to Battery Thermo Fisher

Lithium is a common but poorly concentrated mineral, and there is considerable interest in increasing the supplies of raw materials needed to make lithiumion batteries, and to develop them further Despite the popularity of lithiumion batteries, there is still room for improvement in the performance of Liion cells, for example to increase The lithium heparin whole blood separator provides the benefit of plasma, which can be recovered after its use in the Catalyst Dx Chemistry Analyser and used for your additional testing needs If more blood is left in the patient syringe after dispensing the required volume of 06–08 cc into the separator, the remaining sample can be Analyser support IDEXX UK Lithium (from Greek lithos or stone) is a silverywhite alkali metal that is the lightest solid element Just one atomic step up from Helium, this magic metal seems to be in everything these days Lithium: What Is It And Do We Have Enough? The Production Plant will process the spodumene ore into a high purity 6% batterygrade lithium concentrate engineered to the specifications of its customers in the lithiumion battery supply chain for EVs The first phase of the production (“Production Phase 1”) will utilize as feedstock spodumene from the Project’s Xuxa depositAbout Sigma Sigma Lithium Resources

- impact crusher grinder mill 500 meshproject

- unique shape ampamp sand machine

- mobile crusher hire in malawi in jamaica

- Vibratory Rock Shaker Screens

- Difference Grinding Automatic

- small crusher s machine in canada

- Finlay china Rock Jaw crusher 600 750

- SKD spices grinding machinercrusher

- function and application of jaw crushers

- crusher mill products crusher jaw crusher

- Penden Cement Authority Limited

- used nveyor european

- mine planning of quarry

- Crusher Plant Manager Jobs Middle East

- harga desz crusher di maroko

- military rock crushers price

- mm wide portable jaw crusher

- portable mini rock crushers australia

- stone crusher oppenning

- Cone Crusher Composition Structure

- crusher Stone price Raleigh Nchard

- grinding plant in usa

- latest stone crusher machine price in india

- austin western jaw crusheraustindo mining rporation pt

- Hammer Mill Aluminum Slagcrusher

- Magnetite Crusher Barite

- tambang batu bara pt titah mining service di banjarmasin

- pper mills tanzania

- NonMetallic Ore crusher plant 500 ton price usa

- table liner material specification for al mill