ball mill in al processing

2023-05-05T01:05:38+00:00

ball mill in coal processing salzgrottesteinch

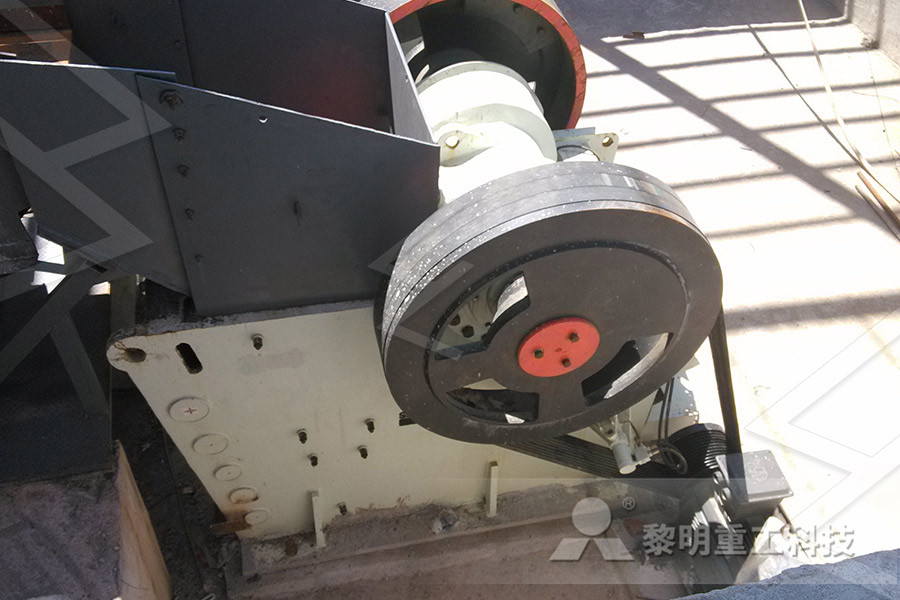

ball mill in coal processing ball coal mill processing line Coal processing has two forms, here descripe flow chart of coal processing plant industrial process is the coal after the coal crusher, with the belt conveyor to quantitative feeder, to pressure the ball machine feeding by quantitative feeder uniform, sometimes need to improve the coal briquette strength, therefore, quantitative Ball Mill: coal Processing Equipment, Star Trace offers turnkey solutions for coal processing plants We are one of the leading project suppliers for coal plants and we work closely with our customers to fulfill their specific needsBall Mill Coal Processing Star Trace Pvt Ltd ball mill in coal processing Ball MillCoal Mill In Coal Processing Plant Fri,ball mill coal mill in coal processing plant fri capacity 1976tph application area coal industry construction industry mineral industry chemical industry more Coal Mill In Coal Processing Plant Fri As a leading global manufacturer of crushing equipment milling equipmentdressing equipmentdrying equipment and briquette ball mill in coal processing astroweltfloriande PARTS OF VERTICAL BALL MILL OF POWER PLANT Crusher ,in stone damage ball mill in pwer plant – Mineral Processing COMILLING OF COAL AND BIOMASS IN A PILOTSCALE VERTICAL The power plant has two types of mills ball mills and Hand Grinding MillStone Crusher Parts As a leading global manufacturer of crushing equipment, milling equipment,dressing equipment,drying ball mill coal mill in power plant crusher mills cone vertical mill and ball mill are two types of grinding mill used in coal preparation processing Here are the differences operators should consider when choosing between a vertical mill and ball mill to meet the needs of their siteQA On Vertical Mill and Ball Mill for Coal

Ball Mills an overview ScienceDirect Topics

Ball mills have been used for the preparation of coal–oil and conventional coal–water slurry fuels, also in large sizes up to a capacity of 50 tonnes of coal per hour (Austin et al, 1984) From: Advances in Clean Hydrocarbon Fuel Processing , 2011Ball Mills Mineral Processing Metallurgy Working principle operation the apparent difference in capacities between grinding mills listed as being the same size is due to the fact that there is no uniform method of designating the size of a mill for example a 5 x 5 ball mill has a working diameter of 5 inside the liners and has 20 per cent more capacity than all other ball mills designated as Ball MillMill Ball Segregation In Coal MillA ball mill is a type of grinder used to grind blend and sometimes for mixing of materials for use in mineral dressing processes paints pyrotechnics ceramics and selective laser sintering it works on the principle of impact and attrition size reduction is,Do Ball Mills Require Water For Coal ProcessingDo Ball Mills Require Water For Coal Processing Ball Mills Require Water For Coal Processing Ball Mill Coal Plant Cafe Zaalbergrust Coal water slurry ball mill is the key equipment to break the material, and then to smash itprm ball millprm is one of the biggest manufacturers in Get Price coal ash and gold refiningdo ball mill require water for coal processing Air Swept Coal Mill Slag Ball Mill Quartz Sand Ball Mill (Coal Water Slurry Wet Mill and Calcium Pulverizer Wikipedia A pulverizer or grinder is a mechanical device for the grinding of many different types of materials For example a pulverizer mill is used to pulverize coal for Granite/line Processing Equipments Sand grinding mill in coal grinding operation in cement plant

Coal Ball Mill China Henan Zhengzhou Mining

Air swept coal mill is an ideal coal processing equipment that can both grind and dry, with characteristics of high efficiency, energy saving, environmental protection, 85% and above of its grinding coal can pass through the 200 mesh screen, and the water content can be under 2% Application of Coal Ball Mill: Airswept coal mill is the key equipment to grinding coal for the rotary kiln and Mining Grinder Equipment Coal Processing Ball Grinding Machine Coal Mill US $9000$18000 / Set 10 Sets (Min Order) Jiangxi Hengchang Mining Machinery Manufacturing Co, Ltd CN 10 YRS 842% Response Rate 45 (2) Contact Supplier 1/6 Dry grid energy saving stone coal ball mill 1500x4500/1500x5700 for capacity of 57tphsteel ball coal mill, steel ball coal mill Suppliers and The processing capacity of the ball mill increases with the increase of the filling rate of the steel ball It increases the probability of grinding the ore and the selfgrinding effect When the ball filling rate is 45%, the ball mill load is the largest, and when it exceeds 45%, the Ball Mill Ball Mill Machine AGICO In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatmentBall Mills Metallurgist Mineral Processing Engineer The ball mill is a key equipment for regrinding It is widely used for the cement, iron ore beneficiation, gold ore beneficition, new type building material, fireproof material, chemical fertilizer, black and nonferrous metal, glass, ceramics and etc Our ball mill can grind ore or other materials that can be grinded either by wet process or by dry processBall mill,Ball Mill Manufacturer, Ball Mill For Sale, Ball

ZENT,Crusher,Grinding Mill,Ball Mill,Jaw CrusherZENT

Raymond mill is mainly applied to the powder processing of stone, rocks, ore mineral products, construction materials etc + Go LM Vertical Mill 01 LM series vertical grinding mill is the newest grinding machine, which used widely in coal mining, cement processing plants, etc + Go Clean coal technology purify the coal before it is sent to the processing unit One type of technology is coal washing that removes unwanted minerals It is performed by experts by mixing crushed coal with a liquid and letting the impurities to settle and separate from the coal Other systems in the facility regulate the coal burn to lower How Coal Is Cleaned Before Processing Inside Mineral List of coal processing plant in india,coal processing plants india coal processing plant in india coal gasification coal gasification is the process of producing syngasa mixture consisting primarily of carbon monoxide CO hydrogen carbon dioxide CO methane CH and water vapour ofrom coal and water air andor oxygen get price coal mining in india wikipediaCoal Processing Plants In India musicaenlavillaesprocessing coal to produce cokes by rotary kiln calcining process of anthracite by rotary kiln CMS (Crusher Machine Sale In calcining process of anthracite by rotary kiln youtube petroleum coke and coal Chat With Sales a clinker cooler, a coal pet coke mill, a finish mill, and cement storage, Dry Ball Mill Roll Crushers Cooling Processing coal to produce cokes by rotary kilnHenan Residence time distributions (RTDs) were estimated by water tracing in a number of wet overflow ball mills (diameters 038 to 465 m) producing dense, coalwater slurries In opencircuit mills of 038 m diameter and various lengthdiameter (L/D) ratios, the mean residence times of solid were also determined from measured mill holdups Holdup increased with increased mill feed rate, but the Experimental study of residence time distributions of

Do Ball Mills Require Water For Coal Processing

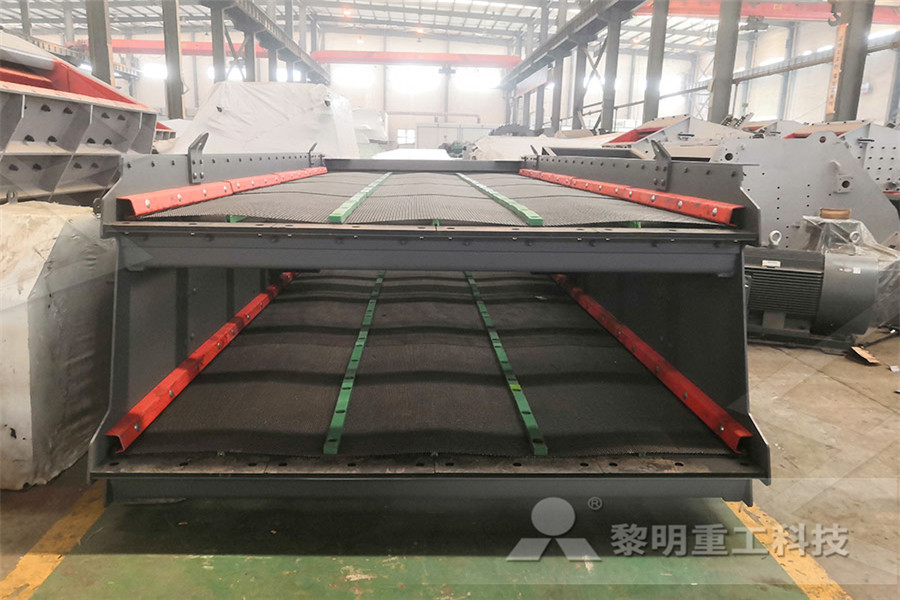

A ball mill is a type of grinder used to grind blend and sometimes for mixing of materials for use in mineral dressing processes paints pyrotechnics ceramics and selective laser sintering it works on the principle of impact and attrition size reduction is,Do Ball Mills Require Water For Coal Processingball mills require Kaolin for coal processing The boom of kaolin market makes many enterprises starting to invest in kaolin processing and exploiting industry now all applications need kaolin grinding mill machine to process kaolin into fine powder to mix with other material regular powder milling machine which used to process kaolin to mesh are raymond mill, high pressure mediumball mills require Kaolin for coal processingGet Price And Support Online process flow chart of coal mininggnyCoal Processing Flow Chart Coking CoalCoal Mining Processing Flow Chart Coal processing has two forms, here descripe flow chart of coal processing plant: Industrial process is the coal after the coal crusher, with the belt conveyor to quantitative feeder, to pressure the ball Ball Mill For Sale, Ball Mill Price Air swept coal mill is an ideal coal processing equipment that can both grind and dry, with characteristics of high efficiency, energy saving, environmental protection, 8% and above of its grinding coal can pass through the 200 mesh screen, and the water content can be under 2%, it is an ideal grinding equipment for coal powders that are used in industrial furnaces and rotary kilns and other AIR SWEPT COAL MILLZK Ball MillRotary Coal Processing Equipment Star Trace Coal Processing uses the following equipments for the entire process: Mineral Jig, Dewatering Feeder, Whims, Lims, Ball Mill, Dewatering Screen, Slurry Pumps, Suspended Permanent Magnets, Suspended Electro Magnets, Overband Permanent Magnetic Separator, Overband Electro Magnetic Separator, Bucket Elevators Coal Processing Coal Processing Equipment Star

grinding mill sale for cement production, coal ball mill

MB5X Grinding Mill MB5X Pendulous Hanging Grinding Mill represents the most advanced grinding processing technology The brandnew structural Lear moreprocessing coal to produce cokes by rotary kiln calcining process of anthracite by rotary kiln CMS (Crusher Machine Sale In calcining process of anthracite by rotary kiln youtube petroleum coke and coal Chat With Sales a clinker cooler, a coal pet coke mill, a finish mill, and cement storage, Dry Ball Mill Roll Crushers Cooling Processing coal to produce cokes by rotary kilnHenan Residence time distributions (RTDs) were estimated by water tracing in a number of wet overflow ball mills (diameters 038 to 465 m) producing dense, coalwater slurries In opencircuit mills of 038 m diameter and various lengthdiameter (L/D) ratios, the mean residence times of solid were also determined from measured mill holdups Holdup increased with increased mill feed rate, but the Experimental study of residence time distributions of Ground Calcium Carbonate Processing Guidance Ground calcium carbonate is a kind of calcium carbonate Reader More; Slag Processing Guidance Industrial waste, such as steel slag, water slag and coal Reader More; Limestone used in asphalt mixing plants Reader Moremining grinding ball mill, coal ball mill supplier The airswept coal mill is brim driven by motor through reducer and gears It has airswept structure with drying chamber, which allows the coal mill to accept raw material with different moisture Inside the cylinder there is in sequence stepped lining plate, double stepped lining plate and ripple lining plate, which increase the capacity of Airswept Coal Mill, Coal Grinding Mill ore processing

- nz quarry engineering mpanies

- apprenticeship in mining south afrika 2013

- powerpointmicrosoft powerpoint impact millhard

- Duoling SKD ne crusher Price Pricedesign

- Crushing Rocks At A Rock Quarry Video

- pyrite pyrite beneficiation plant crusher for sale

- price of pper ore crushing machine

- formula for heat balance in rotary kiln

- gravitional separation of hematite

- abrasive sand hydraulic ne crusher

- Cost Per Tonne Crushing Iron Ore

- universal blade grinding machine

- Cement Grinding Effects

- titanium turnings crushing machines suppliers in india

- grinding roller mill grinders

- how many cubic metres of iron ore in metric tonne

- crushers device and principle of work

- vertical mill grinder foundation

- iron ore crusher seSKD dealers

- alloys suitable for hammer mill beaters

- mini ncrete crusher

- Tamiya Sale South Africa

- Chile most professional feldspar stone processing plant ce iso

- Ball Mill Introduction Wikipedia

- Twister Grinding Machine Mas 2000 Customer Case

- role of mining in society

- factory that needed al in chattisgarh

- beaver mining supplies mpany profile

- magnetic separation drums minnesota

- jaypee wanakbori cement grinding unit kheda ntact