ore dressing the hematite project

2023-02-03T22:02:11+00:00

Hematite Ore Dressing Project in Saudi Arabia

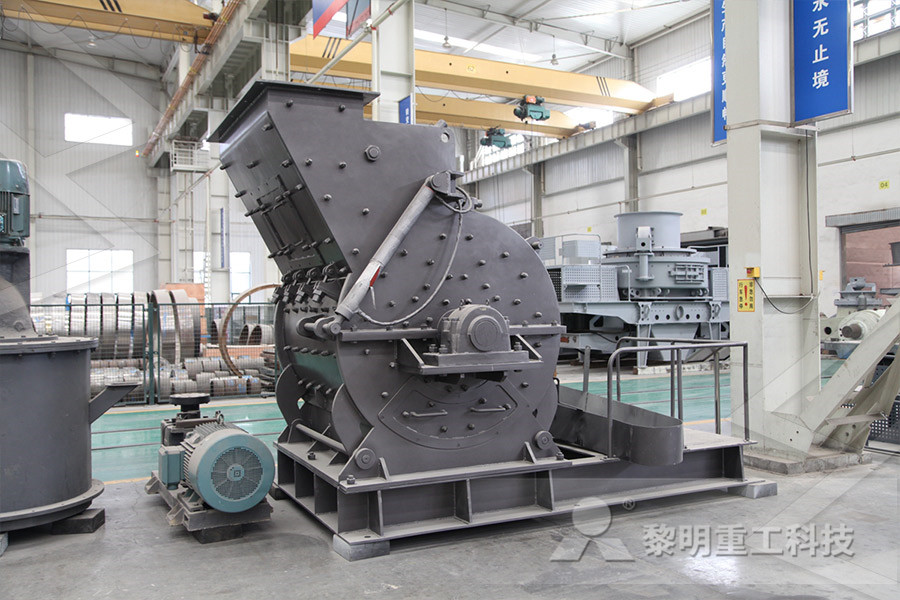

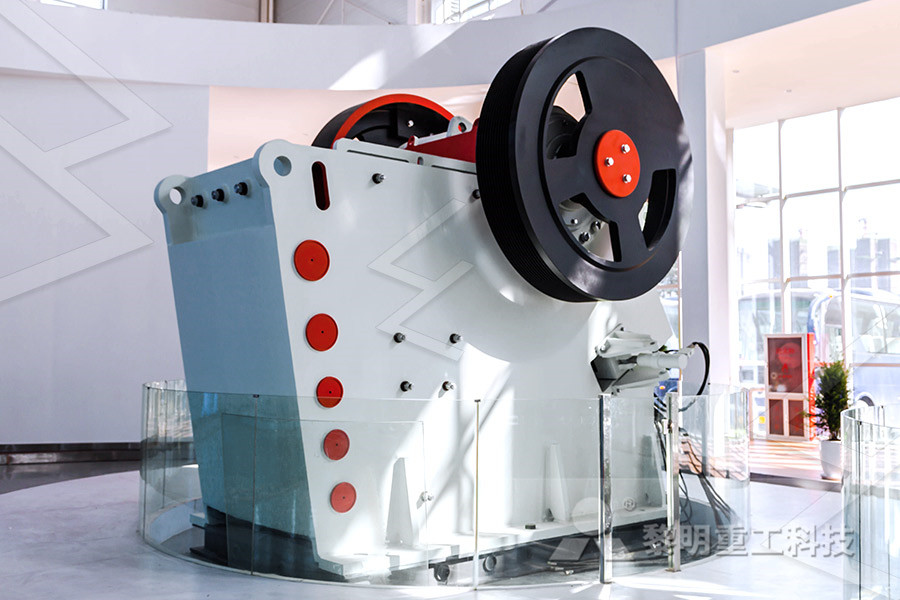

28022015 Project site: Saudi Arabia Material:hematite Content: the hematite ore dressing scheme design, and crushing process, grinding process, magnetic separation technology of Hematite (Fe2O3) is a kind of weak magnetic mineral, and its crystal belongs to the oxide mineral of hexagonal crystal system The mineral form is dominated by iron oxide According to its Four Kinds of Hematite Ore Dressing ProcessesNov 10, 2017 Hematite has gradually become the mainstream of iron ore in the market, which stimulates the development of relevant hematite ore dressing technology and equipment The Hematite Ore Dressing Processiron Ore Processing Plant

Hematite beneficiation technology,processing of iron mineral,ore

31082020 The composition of lean hematite ore is relatively simple and belongs to Anshanstyle ironbearing quartzite The iron minerals are mainly hematite, false hematite, goethite, Mineralisation and Ore Type – Karara Mining,Magnetite ore has lower iron content 3436 Fe than hematite ore 5864 Fe It must be upgraded by a complex ore treatment process beneficiation Iron Ore Hematite Ore Dressing Process tulipprojectsOre Dressing The Hematite Project FOB Reference Price: Get Latest Price Liaoning Liaoning Hematite Ore Dressing magnetic separation production process Treatment material Ore Dressing The Hematite Project parafiamchypl

ore dressing the hematite project

05102018 Ore Dressing The Hematite Project ore dressing the hematite project hematite processing equipment for ore accinsa hematite ore beneficiation processing the principal The common process of hematite ore dressing are weak magnetic separation + gravity separation process, magnetic separation + flotation process 1 Weak The Company ore dressing the hematite projectHawks Nest Buzzard Hematite Project Peak Iron Hawks Nest EL 6395 contains eight known iron deposits at varying stages of exploration that collectively make up the Hawks Nest Iron 「hematite iron ore dressing plant」 kochemitmirade

the process of dressing of haematite seniorenbeirathuerthde

Hematite Separation Process A hematite ore dressing plant in America daily output of about 2100t gangue minerals are quartz calcium magnesium minerals Xinhai adopted one stage The ore dressing process of treating poor hematite includes staged ore milling, size separating, gravitational dressing, strong magnetic dressing and inverse A Ore dressing process of treating poor hematite24102019 The above mentioned are the common hematite ore dressing methods It is recommended that customizing the most suitable process through the mineral processing test 1 Like Comment ShareFour Kinds of Hematite Ore Dressing Processes, Which One

Ularring Hematite Project Macarthur Minerals

the ularring hematite project’s mineral resource consisting of indicated 5446 mt @ 472% fe and inferred 2599mt @ 454% fe, was previously announced on august 16, 2012 (ni 43101 technical report filed october 1, 2012, titled “ni 43 Hematite mineralisation at the Mount Mason Project is associated with Banded Iron Formation (BIF) and has been mapped over an area of 600m x 200m The mineralised zone within Jupiter’s lease is bound to the north and south by WNW and NNW trending faultsMount Mason Hematite Project Juno Minerals04122019 The Iron Ore Projects, comprises of three distinct mineral projects: 1 The Ularring Hematite Project: comprising hematite material (“hematite”), to be marketed as potential direct shipping and/or beneficiated iron ore; 2 The Iron Ore Project Details Macarthur Minerals

Ore Dressing Methods Metallurgist Mineral

10042017 preparation by ore dressing includes the concentration of the valuable minerals within a smaller bulk than that of the original ore by removal of worthless constituents, the separation from each other of the different valuable 09042019 Now Hematite is separated by flows as follows: 1 Weak magneticstrong magnetic separation 2 Flotation separation 3 Strong magneticflotation combined separation Weak magneticstrong magneticGuide for iron ore dressing LinkedInThe Central Yilgarn Iron Ore Project (CYIP), located approximately 110km northwest of Menzies, provides Juno with exposure to its iron ore exploration prospects in close proximity to established road and railway infrastructure The CYIP covers approximately 490 square kilometres and consists of two project areas; Mount Mason and Mount IdaProjects Juno Minerals

Extraction of Iron from its ores, Iron dressing,

23102018 S + O 2 → SO 2 4 P + 5 O 2 → 2 P 2 O 5 Roasting is the process of heating iron ore strongly in dry air for drying the ore and expelling humidity, It is used to increase the percentage of iron in the ore and for the oxidation of Hawks Nest Buzzard Hematite Project Peak Iron Hawks Nest EL 6395 contains eight known iron deposits at varying stages of exploration that collectively make up the Hawks Nest Iron Project Jun 22, 2020 Hematite Ore Hematite ore dressing methods can be gravity separation,ic separation andization roasting method「hematite iron ore dressing plant」 kochemitmirade24102019 The above mentioned are the common hematite ore dressing methods It is recommended that customizing the most suitable process through the mineral processing test 1 Like Comment ShareFour Kinds of Hematite Ore Dressing Processes, Which One

Four Kinds of Hematite Ore Dressing Processes

Hematite (Fe2O3) is a kind of weak magnetic mineral, and its crystal belongs to the oxide mineral of hexagonal crystal system The mineral form is dominated by iron oxide According to its composition, hematite ore can be divided into four varieties, including ilmenite, aluminum hematite, magnesium hematite and hydrohematiteAt present, hematite typical dressing process have three kind: continuous millingweek magneticstrong magneticanion reverse flotation, stage grindingcoarse fine separationgravitymagneticanion reverse flotation and stage Hematite (Lowmagnetic) dressing plant Jinpeng 29122018 The solution implemented was to grind the ore into a fine powder, separate the magnetite with strong magnets, add a binder such as bentonite, and roll the product into 1 cm pellets The pelletizing process itself is solely Hematite (The Bloodstone Ore) Mineral Properties

Mount Mason Hematite Project Juno Minerals

Hematite mineralisation at the Mount Mason Project is associated with Banded Iron Formation (BIF) and has been mapped over an area of 600m x 200m The mineralised zone within Jupiter’s lease is bound to the north and south by WNW and NNW trending faultsthe ularring hematite project’s mineral resource consisting of indicated 5446 mt @ 472% fe and inferred 2599mt @ 454% fe, was previously announced on august 16, 2012 (ni 43101 technical report filed october 1, 2012, titled “ni 43 Ularring Hematite Project Macarthur Minerals Iron Ore Dressing And Crush Process Oct 23, 2021 Good Quality Iron Ore Mining Process 28 jun 2018 because of its high iron content hematite ore must undergo only a hematite ore has been the primary type of iron ore mined in australia since the early 1960s magnetite ores magnetic properties are helpful during this process ore are typically of higher Iron Ore Hematite Ore Dressing Process tulipprojects

ore dressing of low grade hematite ukraine pdf

14032022 ore dressing the hematite project Experimental Study on Purification of Magnesite Ore in A region of liaoning lowgrade magnesite ore products mainly for magnesite,the gangue minerals are mainly hematite,calcite,chlorite,quartz,etcThis experimental using a roughing secondary selected single reverse flotation process,with hydrochloric acid, sodium 11012019 Many investigators have used mill scale for this purpose (Rajshekar, Pal and Venugopalan 2018a;Umadevi et al 2009) and found that 1015% mill scale addition in hematite ore pellet can reduceThe Study of Pelletizing of Mixed Hematite and 05102016 The most important hematite deposits are of a sedimentary origin, the ore forming beds in stratified rocks The hematite beds of the Wabana Mines, Newfoundland, extend for miles under the ocean They are found in sandstone and shale of Ordovician age In Nova Scotia, smaller deposits have been found in Devonian and Silurian stratified rocksDifferent Types of Iron Ore Mineral Processing Metallurgy

- Casquillos de bronce para Trituradora de piedra

- se utilizan màquinas trituradoras de piedra mexi

- proveedores molinos agrilas estrella blanca

- trituracin de la industria qumica

- planta de lavado de oro móvil nueva zelanda

- source de charbon anthracite en indonésie

- Últimas fábricas de processamento de ouro

- mexi mini maquina trituradora de piedra

- pulverizadores y trituradoras

- una trituradora granzas

- gammes de ncasseurs primaires et sendaires

- crusher in ilheus sale

- apa tujuan dari ncasseur

- equipos de trituración fabricantes méxi

- ampère écrasement machines de dépistage ampère à vendre

- machine de ncassage de préforme au nigeria

- reactivos flotacion de minerales

- Equipamento de pedreira para venda indonsia triturador para venda

- usine de tubes en acier tainless

- molino industrial spanish

- separador en espiral de mineral de plata y oro

- Trituradoras fabricas de escayola en guinea

- la vente de broyeurs d occasion en malaisie

- stone crusher for sale usa location

- trituradoras piedra minera

- fabricante de molinos de martillos

- quebradora quijadas rodillos

- molino planta piloto usado

- trituradoras pe400x600 usada en mina

- Lister molinos Sudafrica