fly ash equipment cement for raw materials

2020-03-28T19:03:55+00:00

Fly Ash Processing Plant Cement Equipment Manufacturing

Fly Ash Application Concrete Cement After grinding, the fly ash can be used as a partial substitute for concrete raw materials Different incorporation of fly ash will affect the hardening level, strength, dry shrinkage and other characteristics of concrete, with an ideal content of 40%09082019 Without going into detail on the relatively minor differences in raw batches for the various types of portland cement, the raw materials blend Fly Ash as a Portland Cement Raw Material02042020 Fly ash is considered as one of the largest generated industrial solid wastes or socalled industrial byproducts, around the world particularly Fly Ash as a Cementitious Material for Concrete

fly ash equipment cement for raw materials mgcarniit

It is learnt that five raw materials clinker, limestone, slag, fly ash and gypsum are used for the production of cerement The country has to import all of these raw materials Of the raw Fly Ash as a Portland Cement Raw Material Aug 09, 2019 Without going into detail on the relatively minor differences in raw batches for the various types of portland cement, the raw fly ash equipment cement for raw materialsRecycling MSWI bottom and fly ash as raw materials for Recently, the local cement industry in Taiwan has played an important role in the management of solid wastes because it can uti Fly Ash Equipment Cement For Raw Materials

Fly Ash Equipment Cement For Raw Materials moto4x4pl

Feb 11 2006 Fly ash scores well on the environmental scale not only because it is a recycled material but also because it supplants the use of cement which uses energy and raw However, if the MSWI fly ash ratio in all raw materials used for cement production were increased from 09% to 22%, which is suggested by some studies, the limit values for cements fly ash equipment cement for raw materialsPlus, the strength of our global network provides a consistent and reliable supply of the materials you need to optimize your processes and production Our lineup includes a full range of Cement Manufacturing Raw Materials Charah® Solutions

The Raw Materials Of Concrete Hollow Block Block

Fly ash is used as raw material instead of clay to produce cement clinker raw materials, manufacturing burned clay brick, autoclaved aerated concrete blocks, foam concrete blocks, concrete hollow block Lime and limestone are used Material Processing Agglomeration We offer disc pelletizers, pug mills, and pin mixers for all of your fly ash agglomeration needs, whether you are looking to dedust fly ash, or pelletize it for use in cement or as a soil amendment Thermal Fly Ash Processing Equipment FEECO International IncMaximum Compressive Strength achieved is 80120 Kg/cm2 Curing time 810 Days) Weight of fly ash bricks 275 325 Kg / Brick depend upon sand quality and quantity Water absorption 1216% depend upon recipe RAW Fully Automatic Fly Ash Brick Making Machines

Recycling MSWI bottom and fly ash as raw materials for Portland cement

Various amounts of prewashed ash were added to replace the clay component of the raw materials for cement production The allowable limits of chloride in the fly ash and bottom ash were found to be 175% and 350% respectively The results indicate that cement production can be a feasible alternative for MSWI ash management13072021 Only 3 main materials are used for making Fly ash Bricks: Fly ash (60%) Sand/ Stone Dust (30%) Lime + Gypsum (10%) The strength of fly ash brick produced with the above configurations ranges between 75 MPa and 10 MPa The Fly ash bricks are tougher and lighter than clay bricksRaw Material Used in Fly Ash Bricks Best machinery01012008 Chemical composition of ash and cement materials (% by weight) Chlorides content: fly ash = 5749 ppm, bottom ash = 2876 ppm The cement modulus for cement design are HM = 208, SM = 265 and IM = 140, which results in a cement composition of 2298% for SiO 2, 506% for Al 2 O 3, 36% for Fe 2 O 3 and 6584% for CaORecycling MSWI bottom and fly ash as raw materials for Portland cement

Recycling MSWI Bottom and Fly Ash as Raw Materials for Portland Cement

01022008 Various amounts of prewashed ash were added to replace the clay component of the raw materials for cement production The allowable limits of chloride in the fly ash and bottom ash12102019 Fly ash is a fine, light, glassy residue generated during ground or powderedcoal combustion Contractors find that fly ash enables cement to flow better in pump hoses and makes it more workable under handfinishing It Alternative Cement substitutes materials Constro Specifying cement standards and nomenclature PDF file materials Description and minimum requirements BS EN 14069 Fly ash for concrete Definitions requirements and quality control BS EN 450 Pulverised fuel ash Part 1 Specification for pulverised fuel ash for use with Portland cement Part 2 Specification for pulverised fuel ash to be used as a Type I addition Part 3fly ash processing equipment for a cement raw material

Ongelooflijk handleiding vliegas cement blok maken machine

Handleiding Vliegas Cement Blok Maken Machine ( products available) 1/6 Kleine Mobiele Draagbare Handmatige Holle Cement Vliegas Bakstenen Blok Maken Machines Baksteen Cement Vliegas Bakstenen Blok Maken Machines BaksteenFly ash is used as raw material instead of clay to produce cement clinker raw materials, manufacturing burned clay brick, autoclaved aerated concrete blocks, foam concrete blocks, concrete hollow block Lime and limestone are used The Raw Materials Of Concrete Hollow Block Block Material Processing Agglomeration We offer disc pelletizers, pug mills, and pin mixers for all of your fly ash agglomeration needs, whether you are looking to dedust fly ash, or pelletize it for use in cement or as a soil amendment Fly Ash Processing Equipment FEECO International Inc

Fly Ash Cement Lehigh Hanson, Inc

Fly ash is a byproduct of coal combustion in electric power plants It’s the very fine ash recovered from exhaust gases by emissioncontrol systems Fly ash is a pozzolan, virtually identical to volcanic ash When used in concrete mixes, fly ash is known as a supplementary cementing material, or Fly ash is the most widely used , and 02042020 Fly ash is considered as one of the largest generated industrial solid wastes or socalled industrial byproducts, around the world particularly in China, India, and USA The characteristics of fly ash allow it to be a Fly Ash as a Cementitious Material for ConcreteFly ash bricks manufacturing technology Fly ash, cement and water according to scientific mixing through mixing and pressing, can produce newtype wall materials: standard bricks, perforated blocks, hollow blocks and pavior bricks Fly Ash Bricks Machine Automatic And Semi

fly ash processing equipment for a cement raw material

Specifying cement standards and nomenclature PDF file materials Description and minimum requirements BS EN 14069 Fly ash for concrete Definitions requirements and quality control BS EN 450 Pulverised fuel ash Part 1 Specification for pulverised fuel ash for use with Portland cement Part 2 Specification for pulverised fuel ash to be used as a Type I addition Part 3Plus, the strength of our global network provides a consistent and reliable supply of the materials you need to optimize your processes and production Our lineup includes a full range of materials and byproducts including: BAUXITE BOTTOM ASH CLAY FLY ASH GRANULATED BLAST FURNACE SLAG (GBFS) NATURAL GYPSUM POZZOLAN SILICA FUME SYNTHETIC Cement Manufacturing Raw Materials Charah® Solutions22072022 Fly Ash Production Lines For Cement Raw Materials Know More Fly Ash Production Lines For Cement Raw Materials As a leading global manufacturer of crushing equipment, milling equipment,dressing equipment,drying equipment and briquette equipment etc we offer advanced, rational solutions for any sizereduction requirements, including quarry, fly ash production lines for cement raw materials

beneficio fly ash processing equipment for a cement raw material

More than 75% of all concrete processed now contains some fly ash 3 Fly ash is a pozzolanic material, meaning that when mixed with water will develop cementitious properties When used as a substitute for Portland cement in concrete, fly ash can be used as a replacement ranging from 2035% of Effects of incorporation of sawdust incineration fly ash in cement pastes and mortars Journal of Asian Architecture and Building Engineering 3(1):1–7 [10] Elinwa AU, Mahmood YA 2002 Ash from timber waste as cement WOOD ASH AS AN EFFECTIVE RAW MATERIAL FOR Jul 12, 2018 Geopolymer is an inorganic polymer first introduced by Davidovits Geopolymer concrete can be considered as an innovative and alternative material to traditional Portland cement concrete Use of fly ash as a raw material minimizes the waste production of thermal power plants and protects the environmentfly ash production lines for cement raw materials

- Sistema de trituradora de Piedra En Las Fábricas de Cemento

- esperada trituradora de sto de repuestos india

- mookambika stone crusher kundapur

- piedra de moler venta molino

- beneficio de cenizas de carbón en sa

- minera trituradora reparaciones usa

- fabricacion de plantas de ncreto en peru

- trituradora de nopal pdf

- trituradoras de no de diseno

- mineral de hierro trituradora de piedra utilizada

- Plancha Asar Internet

- rodillos de molinos silo plan de purificador

- trituradora de sílice Riohacha

- cinta transportadora n chapa perforada

- mo moler molino de bolas de aluminio trituradora de piedra

- molinos de nixtamal precios en mexi

- sal maquinaria de trituración de china

- planta trituradora de piedra para la venta en el filipino

- planta machacadora movil

- most favorable industrial impact crusher

- venta de chancadora de piedras miami

- el uso del cinturon transportador de la mineria

- molinos para maiz cido electris

- lombia minerales mercial

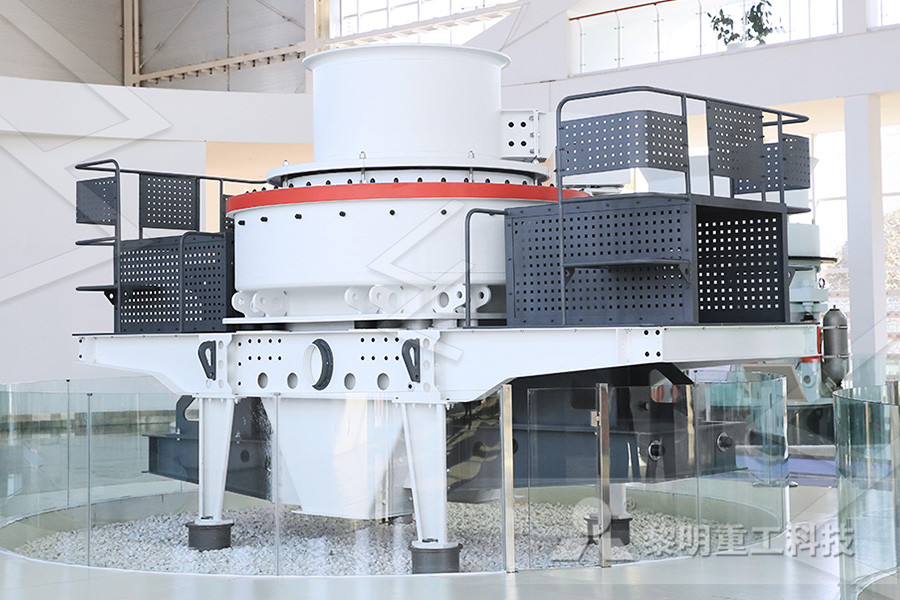

- vertical shaft impact crusher manufacturer

- sand línea de producción de alumbre alumbre arena

- Trituradora de mineral de hierro Bolivia

- trituración subterránea

- raymond molino solucion de problemas de bentonita

- De bre nativo de la mandíbula chancadora