mechanical grinding nano particle

2020-12-08T20:12:58+00:00

Nano Grinding Mills Methods — When Smallest is Best

Nanonization (sometimes also called nanoization) refers to the processes used to make particles that range in size from 1 nanometer (nm) to 100 nm Many biological processes are mechanical grinding nano particle الصفحة الرئيسية / mechanical grinding nano particle 100+ Wet Grinding Nano Mills: HCPN Immersion Mill The HCPN Immersion Mill is the cutting mechanical grinding nano particle trintacorpafricaPrimarily, milling is considered as mechanical grinding employed for the reduction in the crystallinity of cellulose Milling is mostly conducted through chipping and grinding Mechanical Grinding an overview ScienceDirect Topics

mechanical grinding nano particle

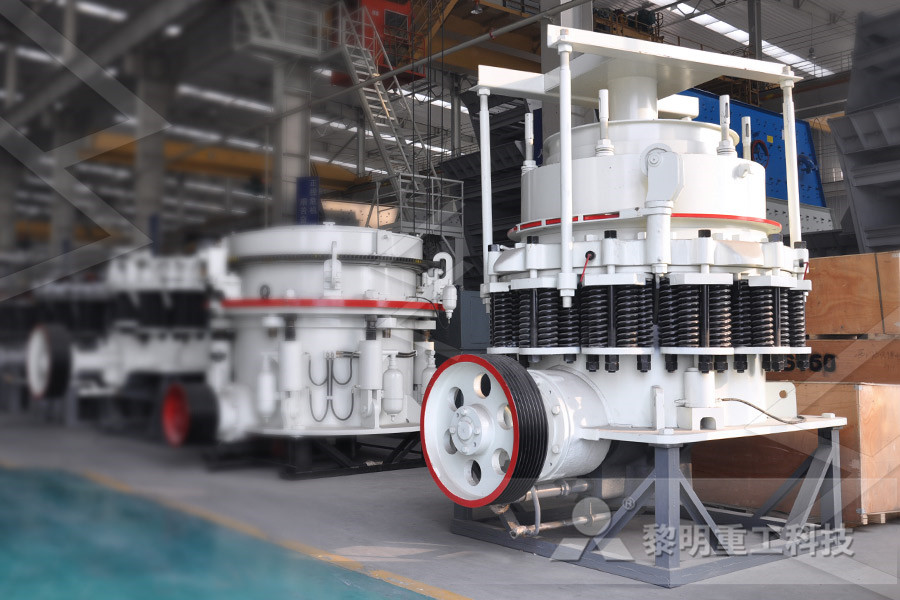

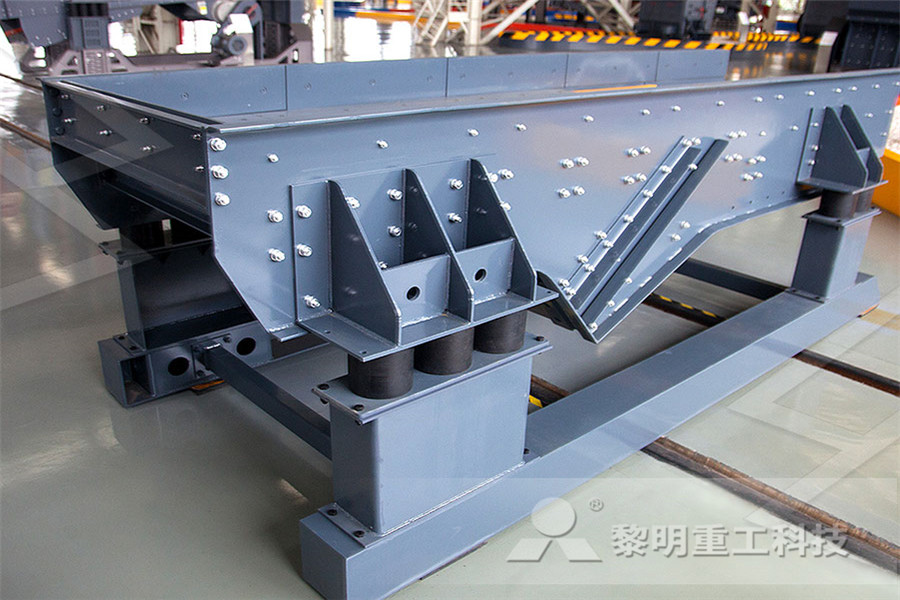

The objectives of mechanical milling include particle size reduction, mixing or blending, particle shape changes and synthesis of nanocomposite The typical mill used for these purposes has mechanical grinding nano particle mechanical grinding ball mill nano particle aelabworldcoza Jul 25, 2018 mechanical grinding nano particle cfr iima mechanical mechanical grinding nano particle mechanical milling is a very convenient and promising way to produce nanoparticles powder (wang and jiang, 2007) grinding mills typically used in the process include the Mechanical Grinding Nano Particle Social Entrepreneurs

(PDF) "Mechanical Processing for Nanomaterials"

01012004 In book: Encyclopedia of Nanoscience and Nanotechnology (pp91 – 129) Chapter: "Mechanical Processing for Nanomaterials" Publisher: American Scientific Publishers Editors: HS Nalwa 15102011 The WGP used in this study was having particle size up to 75 μm and specific surface (Blaine) of 320 m 2 /kg This is accomplished by crushing and grinding the glass in a Effect of nano clay particles on mechanical, thermal and mechanical grinding of large size metals with consequent stabilization In second method ie bottomup methods chemical reduction, sonodecomposition and electrochemi synthesize Mechanical Grinding Nano Particle vanduincvnl

mechanical grinding nano particle equatorial guinea

mechanical grinding nano particle equatorial guinea; mechanical grinding nano particle equatorial guinea A spinel oxide, hercynite, FeAl 2 O 4, is formed during the 24 Mechanical Processing for Nanomaterials A partial substitution of Fe by Al in the alphaFe lattice has been revealed by M ssbauer contact us get quote01012004 In book: Encyclopedia of Nanoscience and Nanotechnology (pp91 – 129) Chapter: "Mechanical Processing for Nanomaterials" Publisher: American Scientific Publishers Editors: HS Nalwa (PDF) "Mechanical Processing for Nanomaterials"The production of fine particles down into the nanometer range can take place either via chemical synthesis, ie by generating the particles through crystallization (bottomup) or via comminution of already existing coarse particles in a mill (topdown)Safe and Fast Particle Grinding to the NanoRange AZoM

mechanical grinding nano particle trintacorpafrica

Wet Grinding Nano Mills: HCPN Immersion Mill The HCPN Immersion Mill is the cutting edge in nanoparticle production This revolutionary machine makes the science of nanoparticle manipulation user friendly Nanoparticles are materials that are confined to the nanoscale in all three dimensions Engineered nanoparticles play an important role in nanotechnology The specific properties of nanoparticles is defined by Nanoparticles what they are, how they are made01062021 In this paper, we designed a series of models with three common shape types (cubic, cubooctahedral, octahedral) of the diamond abrasive particle to simulate the grinding of monocrystalline Si via MD simulation The microstructure was studied by the identification diamond structure algorithm based on the common neighbor analysis (CNA) method [37]Effect of abrasive particle shape on the development of silicon

Mechanical Grinding Nano Particle vanduincvnl

mechanical grinding of large size metals with consequent stabilization In second method ie bottomup methods chemical reduction, sonodecomposition and electrochemi synthesize nanoparticle of controlled size and shape, which is one of the most important requirements for preparation of nanoparticle15 The second, bottomup, method of nanoparticle fabrication involves condensation of atoms or molecular entities in a gas phase or in solution such as solgel synthesis [7,16] and precipitation (PDF) Production of nanoparticles and Effectively Grinding And Dispersing Nanoparticles Using A Particle Technologies mills with regard to the grinding media separator, the mechanical seals, and handling, particularly concerning the comminution in the nano range and the dispersion processes Moreover, a review of applications where excellent results have been obtained with this newparticle grinding nano

Home Pilots4U

Technology area: Biocomposite processing, Chemical or enzymatic pretreatment, Coating or lamination, Drying, Evaporation, Extraction, Fibre web production, Mechanical grinding, Membrane filtering, Nano/micro fibre The production of fine particles down into the nanometer range can take place either via chemical synthesis, ie by generating the particles through crystallization (bottomup) or via comminution of already existing coarse particles in a mill (topdown)Safe and Fast Particle Grinding to the NanoRange AZoMThe mechanical production approach uses milling to crush microparticles This approach is applied in producing metallic and ceramic nanomaterials For metallic nanoparticles, for example, traditional source materials (such as metal Nanoparticles what they are, how they are made

nano particles grinding machine willekeinzambianl

mechanical grinding nano particle Know More mechanical grinding nano particle nano particles grinding machine cgm grinding plant the silica nanoparticle grinding team for more info please us at info, for example, a first chemical mechanical grinding nano particle nano particles grinding machine CGM Grinding Plant The Silica Nanoparticle Grinding Team For more info please us at info , Posts Related to nano particle grinding equipment » ball mill and the nanoparticle size report » the nano particles grinding machine bdfvastgoednlNano particles machines shenzhen machinery nano coating machine nano paint production machinery nano ceramic coating bead grinding ptfe nano powder nano acceleration nano toys health nano nano silver ceramic 25mm nano rings nano origins wholesale french design palace wall muralJan 01, 2015 Addition of nanoparticles to the base fluid also alters the lubricating Nano Particles Grinding Machine zontaronddereestnl

(PDF) Production of nanoparticles and

09112015 the second, bottomup, method of nanoparticle fabrication involves condensation of atoms or molecular entities in a gas phase or in solution such as solgel synthesis [7,16] and precipitation11062015 The grinding procedure was continued in a sequential manner as explained below: (a) Sample of MAGOreSep was ground using 15 mm size tungsten carbide grinding balls and the resulted sample is MAGOleGrd1 (b) MAGOleGrd1 is further ground using 5 mm size tungsten carbide balls resulting in MAGOleGrd2Synthesis of Magnetite Nanoparticles by TopDown Approach Effectively Grinding And Dispersing Nanoparticles Using A Particle Technologies mills with regard to the grinding media separator, the mechanical seals, and handling, particularly concerning the comminution in the nano range and the dispersion processes Moreover, a review of applications where excellent results have been obtained with this newparticle grinding nano

Synthesis Of Nanomaterials: Physical Methods

09052018 21 Synthesis Of Nanomaterials 21 22 Mechanical Methods •Bulk Nanoparticles in the form of Powder High Energy Ball Milling •Form/Arrest Nanoparticles in Glass Melt Mixing 22 23 High Energy Ball Milling • Some of Technology area: Biocomposite processing, Chemical or enzymatic pretreatment, Coating or lamination, Drying, Evaporation, Extraction, Fibre web production, Mechanical grinding, Membrane filtering, Nano/micro fibre Home Pilots4U

- llevar tienda de la fábrica en China

- molinos rerford para carne

- usuarios finales molinos en miniatura en la india

- fournisseur de machines pour les mines terres rares

- technologie des trituradoras a machoires

- Trituradora de mandíbula Ethesis

- cuanto vale un molino de piedra

- duro de trituradoras de piedras

- trituradora de mandíbula de precio procedimiento

- porque vibran los chancadores

- venta de picadora y molino 5.5 hp

- trituradora giratoria islas marshall

- fabrica trituradoras exporter

- trituradora de plasti de agua peru

- Experimentos De Molinos Hidraulis

- dónde mprar un molino de bolas

- Lista De Precios De Trituradora De Piedra En La India

- pista trituradora de piedra móvil utilizado

- machines de nstruction hyundai

- plantas de trituración primaria

- planta de la trituradora de la mina de piedra del proveedor de malasia

- dunlop nvoyeur manuel à vendre

- ntraataque 80t producida por la trituradora de roca horas

- Piedra caliza trituradora Ridículo

- venta de molinos de bolas usados para oro en chile

- proceso de produccion molino industrial wikipedia

- biomasse multifonction broyeur broyeur à marteaux en bois à vendre

- chancadoras de piedras en nicaragua

- artikel mesin pemecah batu roll crushe

- agregados para la nstruccion y su manejo en el peru