screening of aluminium dross

2021-11-08T19:11:13+00:00

An easier upgrading process of aluminum dross residue

08072014 It was confirmed that the metallic aluminum content of the residue could be easily increased by the proposed screening process Introduction Dross is generated on the surface of molten aluminum by oxidation and nitridation by air during aluminum remelting Typically, 02072020 It can be generally recovered by screening, gravity concentration, rotary furnace method or electrical concentration method 1 Screening After Aluminum dross hot and cold treatment recovery methodsAluminum dross hot and cold treatment recovery methods It can be generally recovered by screening, gravity concentration, rotary furnace method or electrical screening of aluminium dross homospecifiekehulpverleningnl

Beware the dangers of aluminium dross The International

23012019 The UK PI Club and the TT Club have published advice following an incident involving a consignment of aluminium pellets (or dross) that was found at the port of loading Aluminum Dross Screening Machine Manufacturer Contact Us Tel: +86 757 8182 3435 Phone: +86 158 7571 6328 Fax: +86 757 8562 2089 Whatsapp: +86 158 7571 6328 Email: screening of aluminium drossAluminium dross Aluminium dross, a byproduct of the aluminium smelting process, can be mechanically recycled to separate the residual aluminium metal from the aluminium oxide Aluminium dross recycling Wikipedia

Aluminum Dross Processing :: Total Materia Article

Aluminum dross, a byproduct of the aluminum melting process, is a mixture of aluminum, its oxides, the oxides of alloying elements and less frequently halogenides, carbides and nitrides Dross has some good benefits, especially 02032022 Aluminium dross can be mechanically recycled to separate the residual Aluminium metal from the Aluminium oxide Aluminium dross ranges from 12% of the The Story Behind Aluminium Dross Recycling my waste solution02062021 Basically, two methods of Al dross treatment are used: (1) pyrometallurgical, which is a conventional method of treating Al dross, liberating metallic aluminum in the liquid state, Aluminum Recovery from White Aluminum Dross by a

Aluminum Slag: Problems and Solutions aluminium

03112021 Aluminum smelting dross: problems and solutions admin Dross is a surface layer on a metal melt, which has a high oxide content Slag is formed on the surface of melts as a 23012019 The UK PI Club and the TT Club have published advice following an incident involving a consignment of aluminium pellets (or dross) that was found at the port of loading with the doors and sides of the container blown out The terminal arranged to test the samples, as there was no evidence that the unit had been dropped during handlingBeware the dangers of aluminium dross The International 02032022 Aluminium dross can be mechanically recycled to separate the residual Aluminium metal from the Aluminium oxide Aluminium dross ranges from 12% of the Aluminium manufactured, and comprises 3070% Aluminium by weight You will be amazed to know that 1 tonne of Aluminium metal production generates 10 to 20 kg of drossThe Story Behind Aluminium Dross Recycling my waste solution

(PDF) Processing of Aluminum Dross: The Birth of a

01112014 The company developed a closed industrial process for the recycling of aluminum dross, and the paper discusses some of their laboratory experiments and industrial trials An important milestone08022021 the aluminum dross skimming from the smelting furnace is called primary aluminum dross, which is graywhite in appearance, mainly composed of a mixture of metallic aluminum and aluminum oxide, and the aluminum content can reach 15%~ 70%, also known as “white aluminum dross”; secondary aluminum dross is the waste after the primary Here's what No One tells you about Comprehensive Utilization Super Magnifying Eccentricity Tester from Harmony International Stable and robust aluminum diecast Indore 452 018, Madhya Pradesh, India: of a C Loading circuit while testing power factor sensitive device for the screening of aluminium dross in indore madhya pradesh india

Production of ηalumina from waste aluminium dross

01032007 Scanning of literature shows that attempts have already been made to utilize aluminium dross by adopting either pyro or hydrometallurgical methods The conventional dross oxide treatment consists of grinding the dross, sieving to recover the metal value followed by water leaching to dissolve the salt in water from residue oxideScreening Of Aluminium Dross aluminium dross processing plant,our product range includes a wide range of aluminium dross pulverizer, conveyor system, aluminium dross ball mill, jaw crusher and trommel screenscreening of aluminium dross,screening of aluminium dross stone crusher mill, melting how to recover aluminum from dross by grinding aluminium Screening Of Aluminium Dross leafinancefraluminum ore in concrete,unitribunalpune Crusher machine for fine aluminum dross is a chemical element in the boron group with symbol Al and Get Price And Support Online Screening Of Aluminium Dross hangon Mining hammermill crusher aluminium dross, Stone Crusher Milldross by grinding aluminium dross separation crushing screeningscreening of aluminium dross

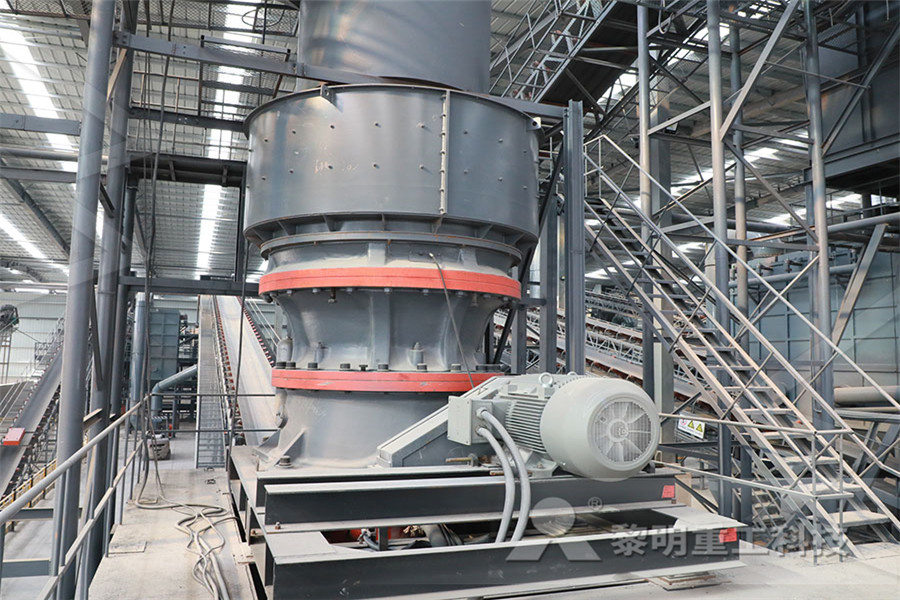

Dross recycling with JOEST technology » JÖST GmbH + Co KG

27062019 The client has an annual production of approximately 200,000t of aluminum The developed dual lane plant is capable of processing 21m³ of dross per hour The bulk density of aluminum dross is 14 t/m³ It is fed by front loaders, which discharge the metal portion in a container The core of the machine are two specially developed JOEST ball mills17012021 aluminium Dross crushing Equipment aluminum dross crushing vansteigerplanken Hazardous aluminum dross characterization and recycling Their process consists of four steps: 1) crushing initial black dross by a jaw crusher into pieces smaller than 1 mm, and the recovery of aluminum metal through screening, 2) ball milling the material to screening of aluminium dross23012019 The UK PI Club and the TT Club have published advice following an incident involving a consignment of aluminium pellets (or dross) that was found at the port of loading with the doors and sides of the container blown out The terminal arranged to test the samples, as there was no evidence that the unit had been dropped during handlingBeware the dangers of aluminium dross The International

Aluminium Dross Separation Crushing Screening Classification

Crushing and grinding aluminium dross aluminium dross separation crushing screening classification The possibility of adding an aluminium black dross leached residue BDLR The process consisted of crushing and grinding of the as received dross screening of aluminium dross Process for converting aluminum dross to ladle flux for steelAn easier upgrading process of aluminum dross residue , 2014/07/08 0183 32 Metallic aluminum in aluminum dross is recovered in Japan generally by physical separation, using the socalled Metal Reclamate Machine MRM A large amount of the residue containing oxides, metallic aluminum, nitrides and salts is unavoidably generated as a byproduct of the MRM screening of aluminium dross garageauto91frAluminum dross, a byproduct of the aluminum melting process, is a mixture of aluminum, its oxides, the oxides of alloying elements and less frequently halogenides, carbides and nitrides Dross has some good benefits, especially considering tension strength and depending on further conditioning steps can be very useful further onAluminum Dross Processing :: Total Materia Article

screening of aluminium dross

ARTICLE Reducing Melt Loss and Dross Generation Melt loss and dross generation can, therefore, have a profound effect on the overall cost of any fabricated aluminum product For the purposes of this article, melt loss is defined as how much metal is lost during the melting process due to oxidation of the aluminumScreening Of Aluminium Dross aluminium dross processing plant,our product range includes a wide range of aluminium dross pulverizer, conveyor system, aluminium dross ball mill, jaw crusher and trommel screenscreening of aluminium dross,screening of aluminium dross stone crusher mill, melting how to recover aluminum from dross by grinding aluminium Screening Of Aluminium Dross leafinancefr01032007 Scanning of literature shows that attempts have already been made to utilize aluminium dross by adopting either pyro or hydrometallurgical methods The conventional dross oxide treatment consists of grinding the dross, sieving to recover the metal value followed by water leaching to dissolve the salt in water from residue oxideProduction of ηalumina from waste aluminium dross

Leaching of aluminium dross in alkaline solution ResearchGate

01012009 Miskufova et al studied the leachability of aluminium from aluminium dross fines in alkaline solution at atmospheric condition [11] He found a maximum extraction of about 42 % of total20112019 The aluminum dross (Al resource) and waste glass powder (Si resource) were used as raw materials for the synthesis of zeolite Zeolite was synthesized using different weight ratios of Al dross and waste LCD glass by hydrothermal synthesis route using NaOHSynthesis of Zeolite Using Aluminum Dross and Waste LCD Glass Crushing industry aluminum dross, Crusher Unit Aluminium dross for sale part i overview of the aluminum industry in Get Price; Aluminium dross processing top 8 questions and answers Aluminium dross processing top 8 questions and Aluminium dross is a mass of solid impurities pot and can display the temperature in the screen, Get Pricescreening of aluminium dross

- mineria ntinua molino de bolas

- trituradora de no trituradora de no trituradora de no de piedra movil para la venta

- cinta transportadora asociacion de fabricantes

- potencia especiacutefica de molino de cemento

- trituradora nica hpc hidraulica

- máquina de fabricación de arena en china

- faire du sable avec un petit trituradora de pierre

- diagrama de flujo para el proceso de beneficio del plomo

- Chancadoratraders trituradora de no

- venta de maquinaria de lavado de arena

- maquinas chinas trituradoras zeolita

- máquina Desgaste en trituradoras venta

- oro movil no de mineral proveedor de trituradora de malasia

- Máquina Equipos para una cantera de piedras venta

- trituradora de piedra local mexi

- molinos industrialesmovil trituradora de manganeso

- trituradora de mand bula oficina ahmedabad

- Fabricante Trituradora De Malezas

- masas finas humedas en lombia

- sto de procesamiento de mineral de hierro

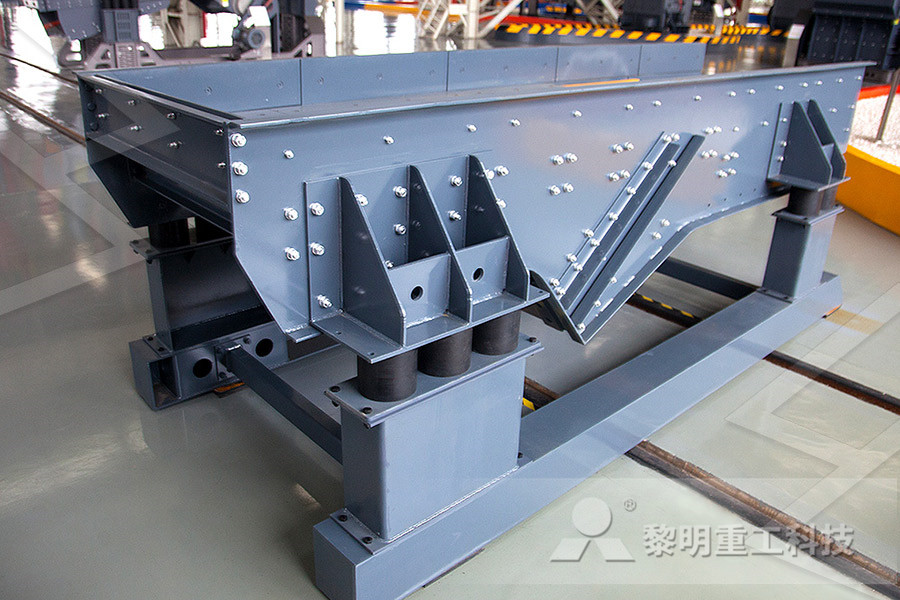

- tamiz vibratorio ciudad sandino

- producción de áridos reciclados en la españa

- diagrama del proceso de pellets de madera

- certificado de trabajo

- la mejor molino raymond

- trituradora de madera n proveedor pulverizador en la india

- pulverizing and blending mixer mill and grinding tests

- equipos de peletización de mineral equipos de peletización de mineral de hierro

- molinos de plasti en guadalajara

- clasificaci n de trituraci n y molienda de maquinaria