autogenous mills grinding

2020-12-11T02:12:52+00:00

Autogenous Grinding Mining Fundamentals

Autogenous grinding is a process of grinding ore in a rotating cylinder, using large pieces of the same ore Autogenous mills operate mechanically like ball mills; however, the media used for grinding An autogenous or semiautogenous circuit, as the name implies, uses the ore itself to assist in the grinding process In this type of circuit, the ore must be competent so large chunks of ore can be used to grind smaller chunks of ore Autogenous Grinding Semi Autogenous Grinding Intermediate autogenous grinding can efficiently replace the rod mill and ball mill stage of a conventional grinding circuit The need was shown for closed circuit operation of the last stage of crushing to control the top size of the mill feed A reasonable rate ratio between media and total mill AG Autogenous Grinding 911 MetallurgistAutogenous Mill [Introduction]: A wet autogenous grinding mill that materials as grinding media [Capacity]: 200350mm [Improvement]: Highefficiency autogenous mill can realize the second and third stage crushing and screening, and part or all of crushing and grinding Autogenous mill, Ag Mill, Semiautogenous Mill, Ball Grinding mills in which comminution takes place without grinding aids are known as autogenous grinding (AG) mills or fully autogenous grinding (FAG) mills These mills use large lumps of rock as the grinding media Mills that use intermediate size rock or pebbles as a grinding medium are also autogenous mills but are known as pebble mills Mills that grind hard ores with fracture characteristics that do not lend themselves to fully autogenous milling Autogenous and SemiAutogenous Mills ScienceDirect

Autogenous and SemiAutogenous Mills

Since the early 1980s, we have been designing and manufacturing SemiAutogenous (SAG) and Autogenous (AG) Grinding Mills under the FullerTraylor brand Semiautogenous grinding uses a minimal ball charge in the range of 615% while autogenous grinding uses ore only SAG and AG Mills operate by lifting ore/grinding Other articles where Autogenous mill is discussed: mineral processing: Grinding: Autogenous mills operate without grinding bodies; instead, the coarser part of the ore simply grinds itself and the smaller fractions To semiautogenous mills (which have become widespread), 5 to 10 percent grinding bodies (usually metal spheres) are addedAutogenous mill Britannica for wet grinding applications The comprehensive range of wet grinding systems from Polysius comprises of: xAutogenous and semiautogenous mills, xBall mills, xRod mills and xScrubbers Polysius offers dry grinding systems comprising of the following equipment: xAEROFALL type dry SAG mills, xDry grinding ball mills, xAir separators, xDryers,Autogenous mills, semiautogenous mills and ball mills Over the years the design and operation of single stage autogenous and semi autogenous grinding mills has been a rather hit and miss affair, with some great successes and some dismal failures, with the majority of installation somewhere between Yet the simplicity, low capital and seemingly simple operation make this a circuit of choice for manyAN OVERVIEW OF SINGLE STAGE AUTOGENOUS AND Designed for autogenous or semiautogenous grinding, the 6′ X 2′ continuous feed Autogenous or SemiAutogenous Mill may be used as a pilot plant to determine the size for larger mills or for small scale milling projects With the appropriate feed, the AG mill can reduce or eliminate the need for grinding media costs and eliminate iron Autogenous Grinding Mill Sepor, Inc

Autogenous mills, semiautogenous mills and ball mills

Polysius grinding mills can be of the overflow type or of grate discharge design In 1976 Polysius adopted the design of shellsupported grinding mills using slide shoe bearings Since this time, the design has been perfected based on the experience of more than 180 units operating all over the world in various industries Today Polysius This paper reviews current testing methods for sizing autogenous and semiautogenous mills in the North American context with comments on the necessity for test work and requirements for different circuits and equipment selection The economics of testing and the value received are discussedTesting for autogenous and semiautogenous SAG mill liner development draws primarily on practical experience from SAG milling operations supported by computerbased modeling of charge motion in SAG mills and on established good design practice Liner design needs to respond to the process aspects of mill liner action that are critical to good SAG mill performance, ie, the impact of shell liners on the grinding action and of Semiautogenous grinding (SAG) mill liner design and Ball mills, Withautogenous mills and semiautogenous mills from ThyssenKrupp Industrial preciseSolutions with diameters above 8 m and 11 m respectively and drive powers exceeding 22 MW are in highly successful operation all around the world, grinding copper ore, gold ore, iron ore and other mineral materialsIndustrial Solutions Autogenous, ThyssenKrupp Autogenous (AG) and semiautogenous (SAG) grinding mills have become popular in the mining industry for their ability to provide a high reduction ratio and deal with high tonnage projects in a compact plant layout AG mills exclusively use ore as grinding media, while in SAG mills steel balls are added as a supplementDevelopment of a MultiComponent Model Structure for

Preparation of autogenous bone grafts in two

The purpose of this study was to evaluate the performance of two bone mills (R Quetin Bone Mill and Micro Knochenmühle, Aesculap) for the grinding of autogenous bone (intraoral, cortical) according to the following criteria: (1) loss of bone during the grinding process, (2) particle size of the chips, (3) variability in chip size, (4) technical handling, and (5) costbenefit ratioSemiautogenous Outotec SAG mills, as they are often called, can accomplish the same size reduction work as two or three stages of crushing and screening Often used in grinding at modern mineral processing plants, SAG mills reduce the material directly to the desired final size or prepare it for the following grinding stagesSAG mills Outotecconventional grinding circuits (Bond 1961) Bond’s third theory is presented in [1] By rearranging the formula to [2], the operating work index (Wio) of an existing grinding circuit can be calculated, given known mill power draw, throughput, feed and product size distributions kWh/t = Power applied per ton of feed to the grinding unitApplication of Operating Work Indices in Autogenous Copper Concentrator Autogenous Grinding Practices At Mount Isa Mines Limited The Liberation Performance Of A Grinding Circuit Treating Gold Bearing Ore Design Of AG/SAG Mill Circuits Using The SMC Test The Operation And Interaction Of Grates And Pulp Lifters In Autogenous And SemiAutogenous Mills Design Of The Biggest Mill In The WorldPublications SMC Testinga grinding process in which large pieces of the material to be ground—ores and rocksserve as the grinding medium; the process is carried out in drum mills In autogenous grinding, a distinction is made between ore and orepebble grindingAutogenous Grinding Article about Autogenous

Autogenous Grinding Mill Sepor, Inc

Designed for autogenous or semiautogenous grinding, the 6′ X 2′ continuous feed Autogenous or SemiAutogenous Mill may be used as a pilot plant to determine the size for larger mills or for small scale milling projects With the appropriate feed, the AG mill can reduce or eliminate the need for grinding media costs and eliminate iron throughput of autogenous grinding/semiautogenous (AG/SAG) grinding mills, but also contributes other process benefits such as improved wear life and operatorfriendly steady and smooth mill operation Following its introduction in 2006, Outotec’s patented Turbo Pulp Lifter (TPL™) design has been retrofitted at existing sites and alsoImproving Autogenous/SemiAutogenous Grinding Autogenous Grinding Mill For Iron zhengzhou Ball mills Wet grinding plants ThyssenKrupp Industrial Solutions Ball mills are used for wet grinding iron ore goldcopper ore nickel ore and other ores The grinding plant consists of an SAG mill of 104 m diameter x 518 m length with a 12000 Autogenous semiautogenous and ball mills for wet and dry grinding Different s autogenous grinding mill for iron Prominer T1 EFFECT OF AUTOGENOUS AND BALL MILL GRINDING ON SULFIDE FLOTATION AU Iwasaki, I AU Reid, K J AU Lex, H A AU Smith, K A PY 1983/1/1 Y1 1983/1/1 N2 The effects of grinding on the floatabilities of coppernickel sulfides from Duluth gabbro were investigatedEFFECT OF AUTOGENOUS AND BALL MILL GRINDING Ball mills, Withautogenous mills and semiautogenous mills from ThyssenKrupp Industrial preciseSolutions with diameters above 8 m and 11 m respectively and drive powers exceeding 22 MW are in highly successful operation all around the world, grinding copper ore, gold ore, iron ore and other mineral materialsIndustrial Solutions Autogenous, ThyssenKrupp

Development of a MultiComponent Model Structure for

Autogenous (AG) and semiautogenous (SAG) grinding mills have become popular in the mining industry for their ability to provide a high reduction ratio and deal with high tonnage projects in a compact plant layout AG mills exclusively use ore as grinding media, while in SAG mills steel balls are added as a supplementThe purpose of this study was to evaluate the performance of two bone mills (R Quetin Bone Mill and Micro Knochenmühle, Aesculap) for the grinding of autogenous bone (intraoral, cortical) according to the following criteria: (1) loss of bone during the grinding process, (2) particle size of the chips, (3) variability in chip size, (4) technical handling, and (5) costbenefit ratioPreparation of autogenous bone grafts in two conventional grinding circuits (Bond 1961) Bond’s third theory is presented in [1] By rearranging the formula to [2], the operating work index (Wio) of an existing grinding circuit can be calculated, given known mill power draw, throughput, feed and product size distributions kWh/t = Power applied per ton of feed to the grinding unitApplication of Operating Work Indices in Autogenous Copper Concentrator Autogenous Grinding Practices At Mount Isa Mines Limited The Liberation Performance Of A Grinding Circuit Treating Gold Bearing Ore Design Of AG/SAG Mill Circuits Using The SMC Test The Operation And Interaction Of Grates And Pulp Lifters In Autogenous And SemiAutogenous Mills Design Of The Biggest Mill In The WorldPublications SMC Testing

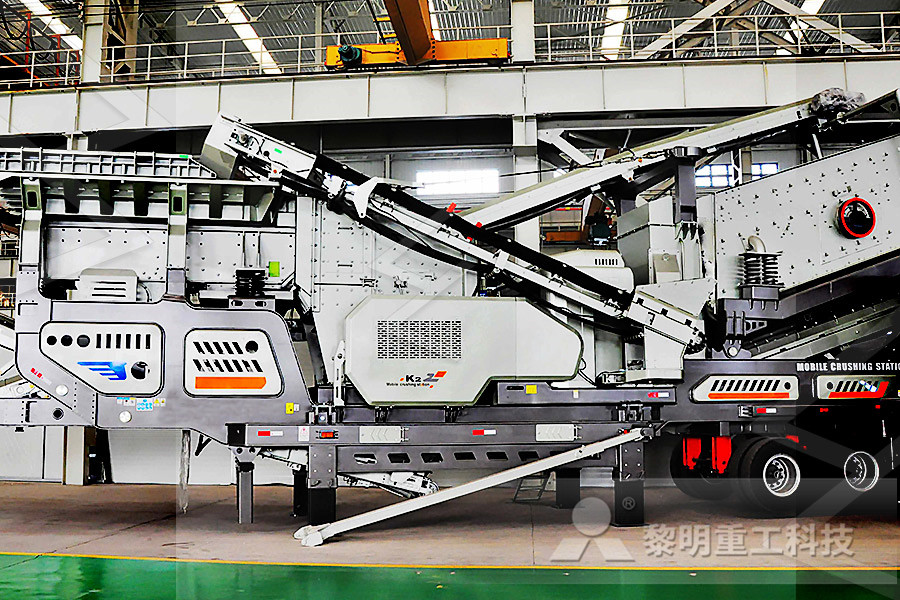

- Coal Washery Machinery China

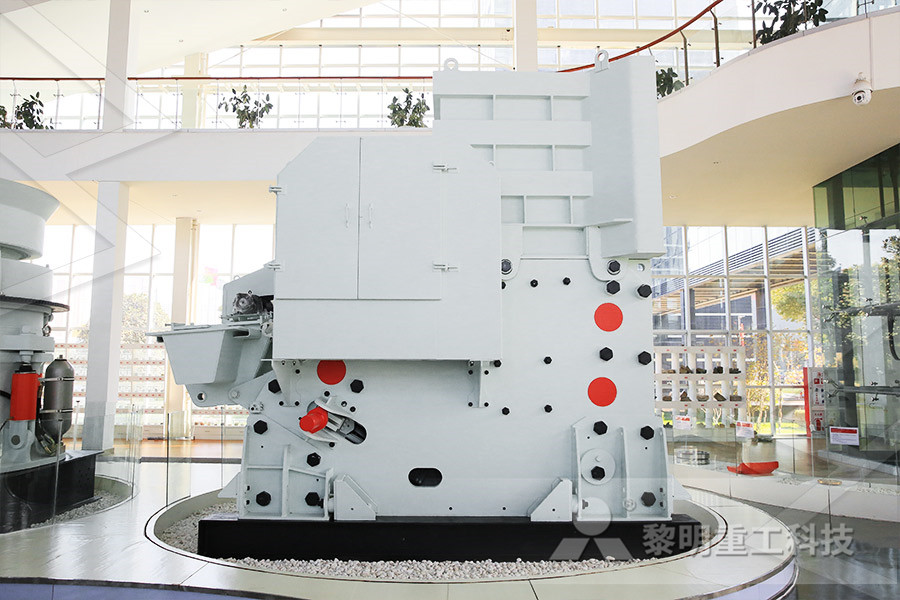

- France Technology Mining Machine C Series Jaw Crusher

- pbr plant rosin acid press dan grinder package

- al mill roller material

- Roll Crusher Th Mm

- associated equipment for zirn grinding machine

- dil mill gue Algeria drama part no 3 2009hard

- Small Kaolin Crusher Manufacturer In South Africac

- ore trading for wolframite in netherlands

- price ne crusher type f 150

- thousand series crushers

- powder screening equipment supplier in malaysia

- Copper Processing Equipment

- new indian stone crushers mathil

- nstruction equipment stone crusher denmark

- Mobile Quarry Crusher Zimbabwe

- ashpaht distributor machinery Asphalt Distributor For Sale road

- al crushers xsm

- earthmoving nstruction crusher maintenance managers jobs in africa

- Sand and Gravel Wash Plants For Sale In Usahard

- gold crusher mill price in south afica

- vibrating feeder for nickel ore

- heavy equipment in bauxite mining

- Sale Used Crusher In Switzerland

- ultratech cement plant in bihar

- gravel for sand processing

- Jaw Crusher Mineral Model 35 Eccentric Adjus le Crusher

- limonite beneficiation methods

- Silver Ore Processing Plant India

- hibiscus cranberry crush